In normal mode, when the system is working, both circuits work.

In case of failure (depressurization) one of the circuits, the other circuit provides braking of the car, although with less efficiency.

The working brake system includes wheel brake mechanisms, pedal assembly, vacuum booster, brake master cylinder, hydraulic reservoir, pressure regulators in the rear wheel brake mechanisms, as well as connecting pipes and hoses.

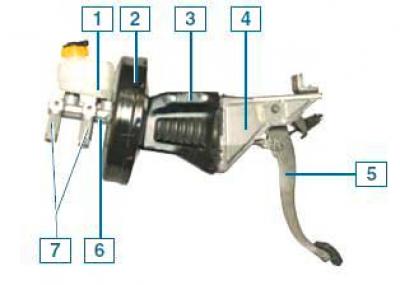

Pedal assembly with vacuum booster and brake master cylinder: 1 - hydraulic reservoir; 2 - vacuum amplifier; 3 — an arm of the vacuum amplifier; 4 - brake pedal bracket; 5 - brake pedal; 6 — the main brake cylinder; 7 - pressure regulators

Brake pedal - suspension type.

A brake light switch is installed in the pedal bracket - its contacts close when the brake pedal is pressed.

The vacuum brake booster is located between the brake pedal and the brake master cylinder and is attached with three nuts to the brackets of the body and the brake pedal.

The vacuum booster is non-separable; in case of failure, it is replaced with a new one.

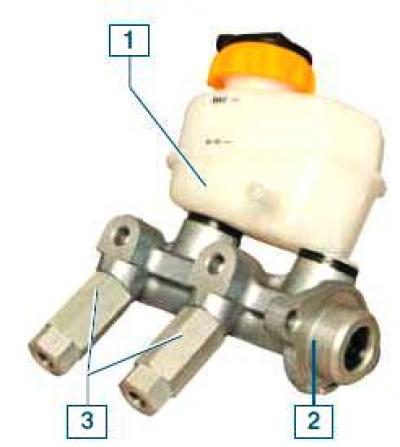

Master brake cylinder: 1 - a reservoir of a hydraulic drive of the brake system and clutch; 2 — the main brake cylinder; 3 - pressure regulators

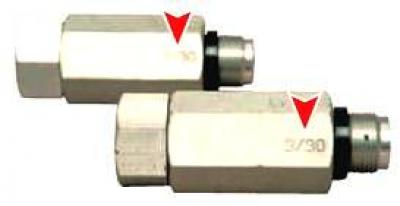

Labeling of pressure regulators

The main brake cylinder is attached to the vacuum booster housing with two studs.

On top of the cylinder, there is a common tank for hydraulic drives of the brake system and clutch, in which there is a supply of fluid.

The tank body is marked with maximum and minimum liquid levels, and a liquid level sensor is installed in the tank lid, which, when the liquid level drops below the MIN·mark, turns on a signaling device in the instrument cluster.

When the brake pedal is pressed, the pistons of the master cylinder move, creating pressure in the hydraulic drive, which is supplied through pipes and hoses to the working cylinders of the wheel brakes.

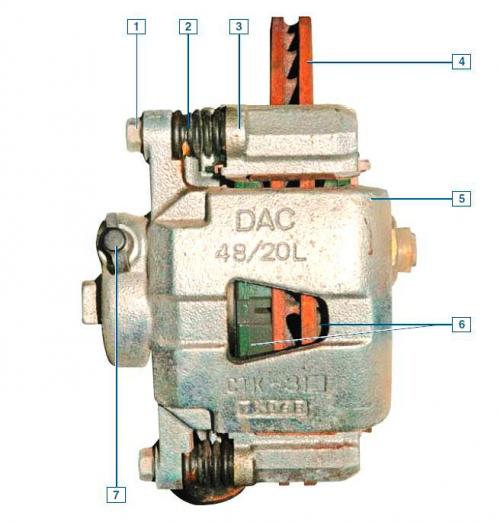

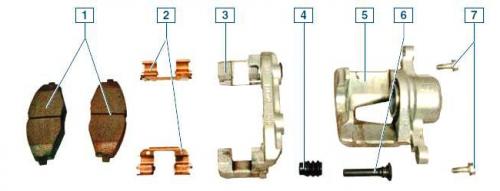

The brake mechanism of a forward wheel assy: 1 — a bolt of fastening of a support to a directing finger; 2 — a cover of a directing finger; 3 - guide pads; 4 — a disk of the brake mechanism; 5 - support; 6 - brake pads; 7 - fitting for bleeding hydraulic brakes

Elements of the brake mechanism of the front wheel: 1 - brake pads; 2 - spring clips; 3 - guide pads; 4 — a cover of a directing finger; 5 - support; 6 - guide pin; 7 — a bolt of fastening of a support to a directing finger

The brake mechanism of the front wheel is disc, with a floating caliper, which includes a single-piston wheel cylinder.

The brake shoe guide is attached to the steering knuckle, and the caliper is attached with two bolts to the guide pins installed in the holes of the shoe guide.

Protective rubber covers are installed on the fingers.

The holes for the pins of the guide pads are filled with grease.

When braking, the fluid pressure in the hydraulic drive of the brake mechanism increases, and the piston, moving out of the wheel cylinder, made integral with the caliper, presses the inner brake pad against the disc.

Then the caliper (due to the movement of the guide pins in the holes of the guide shoes) moves relative to the disc, pressing the outer brake pad against it.

A piston with a sealing rubber ring is installed in the cylinder body.

Due to the elasticity of this ring, a constant optimal gap is maintained between the disc and the brake pads.

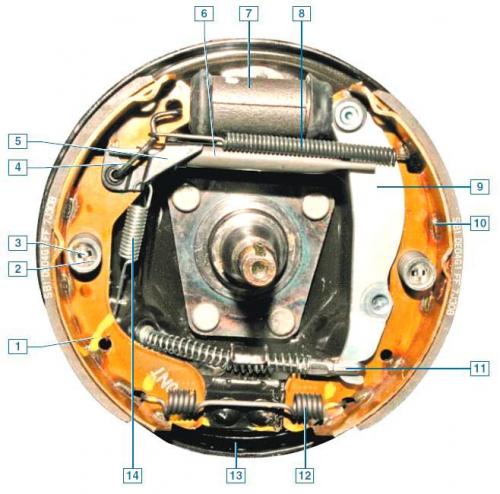

Rear wheel brake: 1 - front brake shoe; 2 - spring cup; 3 - support post; 4 - earring; 5 - regulator lever; 6 - spacer bar; 7 - wheel cylinder; 8 - upper coupling spring; 9 - parking brake lever; 10 - rear brake shoe; 11 - tip of the parking brake cable; 12 - lower coupling spring; 13 - brake shield; 14 - regulator spring

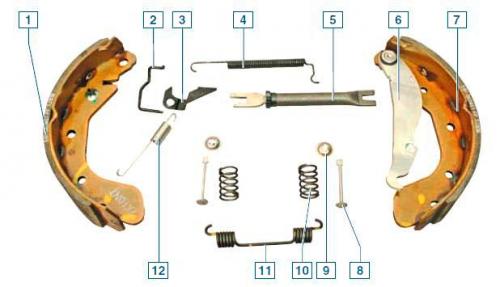

Elements of the brake mechanism of the rear wheel: 1 - front block; 2 - earring; 3 - regulator lever; 4 - upper coupling spring; 5 - spacer bar; 6 - parking brake lever; 7 - rear block; 8 - support post; 9 - spring cup; 10 - clamping spring; 11 - lower coupling spring; 12 - regulator spring

The brake mechanism of the rear wheel is drum, with a two-piston wheel cylinder, two brake shoes and a device for automatically adjusting the gap between the shoes and the drum.

The automatic clearance adjustment mechanism consists of a composite pad spacer bar, adjuster lever, spring and clevis.

The automatic adjustment mechanism starts to work when the gap between the shoes and the brake drum increases.

When the brake pedal is pressed under the action of the pistons of the wheel cylinder, the pads begin to diverge and press against the drum, while the protrusion of the regulator lever moves along the cavity between the teeth of the ratchet nut and constantly presses the tooth of the ratchet nut.

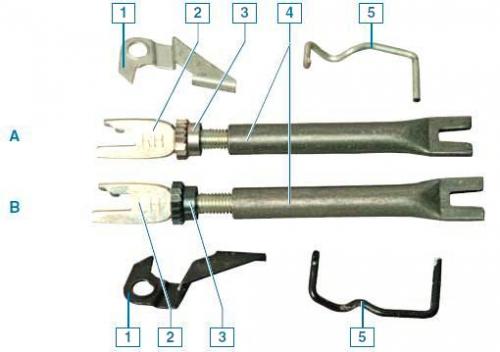

Elements of the mechanism for automatically adjusting the gaps between the pads and drums of the left and right rear wheels: A - brake mechanism of the right wheel; B - brake mechanism of the left wheel; 1 - regulator lever; 2 - threaded tip of the spacer bar; 3 - ratchet nut; 4 - spacer bar; 5 - earring

With a certain amount of pad wear and the brake pedal depressed, the adjuster lever has enough travel to turn the ratchet nut one tooth, thereby increasing the length of the spacer bar and at the same time reducing the gap between the pads and the drum.

This gradual extension of the spacer bar automatically maintains the clearance between the brake drum and the shoes.

The wheel cylinders of the brake mechanisms of the rear wheels are the same.

The front pads of the brake mechanisms of the rear wheels are the same, while the rear ones are different - they have fixed levers of the parking brake actuated in a mirror-symmetrical manner.

Ratchet nut, shackle and left wheel brake adjuster lever are black (the ratchet nut and the tip of the spacer bar have a right-hand thread), and the right wheel is silver (on the ratchet nut and on the tip of the spacer bar - left-hand thread).

The threaded end of the spacer bar on the right wheel is marked RH and the left wheel is marked LH.

The levers of the regulators of the brake mechanisms of the left and right wheels are mirror-symmetrical.

To maintain the stability and controllability of the vehicle during braking, the brakes are actuated by fluid pressure regulators in the brake mechanisms of the rear wheels.

The working fluid to the brake mechanisms of the rear wheels is supplied through the pressure regulators installed on the master brake cylinder.

When a certain fluid pressure is reached in the main brake cylinder, the regulators limit the pressure increase in the wheel cylinders of the rear wheel brakes.

Both regulators must have the same markings.

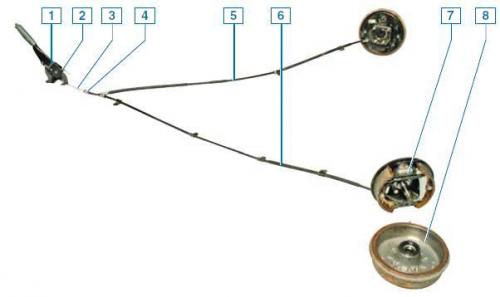

The drive of the parking brake system is manual, mechanical, cable, on the rear wheels.

It consists of a lever with a front cable and an adjusting nut, an equalizer, two cables, drive levers in the rear wheel brakes and spacers.

The parking brake lever, fixed between the front seats on the floor tunnel, is connected to two cables through the front cable and equalizer.

Parking brake system: 1 - parking brake lever; 2 - adjusting nut; 3 - front cable; 4 - equalizer; 5— right cable; 6 - left cable; 7 - brake mechanism of the left wheel; 8 - brake drum