Removing the battery (see Removing the battery). Having loosened the bolt of the terminal connection of the gearbox control rod with the drive input shaft (see Gearbox control drive adjustment), remove the drive shaft from the thrust hole.

Disconnect the wiring harness from the reverse light switch (see Removing the reverse light switch). Removing the vehicle speed sensor (see Removing the vehicle speed sensor and its drive).

Remove the clutch hose adapter from the clutch slave cylinder tube end (see Clutch Hose Replacement).

At the same time, in order to avoid leakage of the working fluid from the reservoir of the hydraulic brake and clutch drives, we pinch the clutch hydraulic hose or insert a plug into the outlet of the hose adapter.

Remove the left mudguard of the engine compartment (see Removing the mudguards of the engine compartment).

Drain the oil from the gearbox (see Changing the oil in the gearbox). Removing the front wheel drive (see Removing the front wheel drives).

We substitute a height-adjustable stop under the engine oil pan, placing a wooden spacer.

Removing the rear support of the power unit (see Replacing power unit supports).

It is possible to dismantle the gearbox in assembly with the gear shift mechanism drive or after removing it.

We remove the gearshift drive assembly with the bracket for the rear support of the power unit. To do this, we disconnect the forks of the output shaft of the drive and the gearshift rod (see Removing the gearshift drive), and then…

... with a "17" spanner, we unscrew the three bolts securing the bracket to the clutch housing.

We remove the bracket for the rear support of the power unit assembly with the gear shift mechanism drive.

Before unscrewing the bolts securing the clutch housing to the engine block, mark their location. This will simplify the subsequent installation of the gearbox, since the clutch housing mounting bolts are different in diameter and length of the rods.

At the top, the clutch housing is attached to the cylinder block with three bolts.

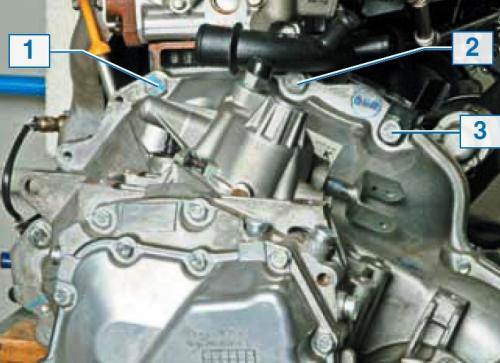

For clarity, we show the location of the bolts of the upper mounting of the clutch housing on the dismantled power unit.

Bolt 1, located under the ignition coils..

... and bolt 3, which also fastens the bracket for the wiring harness, unscrew the head "19".

Bolt 2, located under the inlet pipe of the coolant pump, is unscrewed with a z-shaped key "by 19".

The inlet pipe of the coolant pump interferes with the operation of unscrewing the bolt 2. To give the pipe mobility..

... from the back of the engine with the "10" head, loosen the bolt of its left attachment to the cylinder block (for clarity shown on a dismantled engine).

From the side of the engine crankcase pan, with the "19" head, we unscrew the two bolts of the lower fastening of the clutch housing to the cylinder block, and with the "14" head, three bolts of the lower fastening of the clutch housing to the crankcase pan.

From the side of the gearbox, with the "19" head, we unscrew one more bolt of the lower fastening of the clutch housing to the cylinder block, and with the "14" head, loosen the bolt of the lower fastening of the clutch housing to the engine oil pan.

Having unscrewed the nuts and the bolt securing the base of the fuse and relay mounting block in the engine compartment, we move the block away from the left support of the power unit without disconnecting the wiring harness blocks from the block (see Replacing power unit supports).

With a spanner wrench or a "19" head, unscrew the nut and bolt securing the adapter of the left support of the power unit to the support bracket.

Lowering on an adjustable stop (placed under the engine oil pan) the power unit, removing the pin of the bracket of the left support of the power unit from the hole in the support adapter.

With a "14" head with an extension, we unscrew the three bolts securing the bracket of the left support of the power unit to the clutch housing..

and remove the support bracket.

To facilitate the removal of the gearbox (weighs more than 20 kg), install another adjustable stop under the clutch housing and completely unscrew (from the gearbox side) bolt of the lower fastening of the clutch housing to the engine oil pan.

We remove the gearbox from the engine to the left side member.

We lower the gearbox on an adjustable stop..

...and take it off.

The gearbox can also be removed without disconnecting the gearshift drive and the powertrain rear support bracket from it.

When removing or installing the gearbox, the input shaft of the gearbox must not be supported on the petals of the diaphragm spring of the "basket" of the clutch, so as not to damage them.

Before mounting the gearbox, we apply a thin layer of grease, for example, SHRUS-4, on the splined part of the input shaft.

We check the condition of the two centering bushings pressed into the holes of the cylinder block.

If bushings are missing or deformed, new ones must be installed.

Install the gearbox in reverse order.

After the input shaft of the gearbox is inserted into the splined hole of the driven clutch disc, we send the gearbox to the right until the mating surfaces of the clutch housing, cylinder block and engine oil pan are in full contact. We screw and tighten all the bolts of the clutch housing. We install the supports of the power unit. We finally tighten the clutch housing mounting bolts with the required torques in the following sequence: - tighten the three bolts of the lower mounting to the cylinder block with a torque of 72–74 N·m; - one bottom bolt to the engine sump (next to the hole in the clutch housing under the right front wheel drive) - torque 30–32 N·m; - three more bolts of the lower fastening to the engine crankcase - with a torque of 20–22 N·m.

- we tighten the three bolts of the upper fastening to the cylinder block with a torque of 72–74 N·m.

After installing the gearbox, fill it with oil, adjust the gear shift drive, pump the clutch hydraulic drive.