To remove the "basket" and the clutch disc, dismantle the gearbox (see Removing the gearbox).

With a spanner wrench or a "11" head, we unscrew the six bolts securing the clutch "basket" to the flywheel. We hold the crankshaft from turning with a mounting blade inserted between the teeth of the flywheel and resting on the rib of the gearbox housing.

First, we unscrew the bolts evenly, no more than one turn per pass, so as not to deform the clutch housing spring. As soon as the action of the diaphragm spring weakens, we unscrew the bolts arbitrarily. When unscrewing the last bolt, we support the "basket" and the clutch disc.

We remove the "basket" and the clutch disc.

Installing clutch..

... we orient the driven disk with the protruding part of the disk towards the pressure plate of the "basket"...... and insert the centering mandrel into the hole of the driven disk.

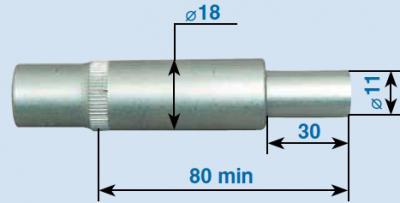

The mandrel can be machined on a lathe from metal, wood, plastic, or made independently by assembling it from two tool heads with suitable diameters and lengths.

Centering mandrel

We introduce the mandrel into the hole of the crankshaft flange and in this position we fix the "basket" of the clutch, evenly (one turn per pass) tightening the bolts.

Finally tighten the mounting bolts to the prescribed torque (see Applications).

Having fixed the "basket" of the clutch, we take out the centering mandrel and mount the gearbox (see Removing the gearbox).