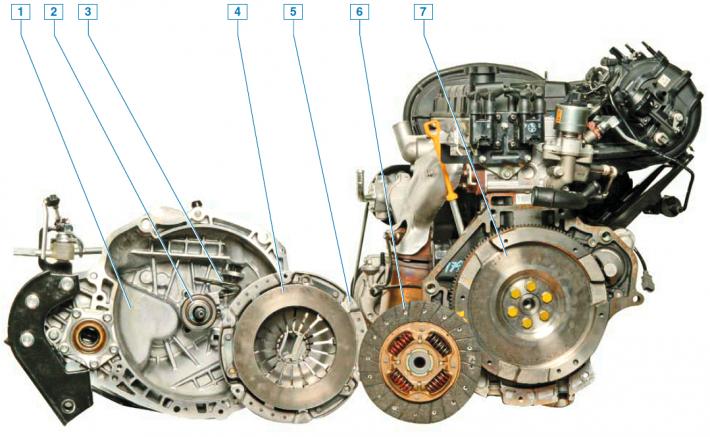

Clutch elements: 1 - clutch housing; 2 - hydraulic drive cylinder with clutch release bearing; 3 — a tube of the working cylinder of a hydrodrive of coupling; 4 - pressure plate; 5 - clutch cover; 6 - driven disk; 7 - flywheel.

casing (basket) clutch: 1 - diaphragm spring; 2 - casing; 3 - elastic steel plates; 4 - pressure plate.

Driven clutch disc: 1 - friction linings; 2 - torsional vibration damper; 3 - idle damper; 4 - hub.

The clutch is single-disk, dry, with a central spring of the diaphragm type. Located in an aluminum crankcase integrated with the manual transmission crankcase and attached to the cylinder block.

The clutch cover is connected to the engine flywheel with six bolts.

By three pairs of elastic steel plates, the casing is connected to the pressure (leading) disk. This node (it is also called the "basket" of the clutch) the assembly is balanced on the stand, so it is replaced entirely. A diaphragm spring is installed in the casing.

Replacing the "basket" is necessary when the annular wear of the pressure spring petals, and if the ends of the petals are not at the same level. We reject the "basket" with a decrease in the effort on the pedals when the clutch is turned off, which indicates a large wear on the surface of the pressure plate or "draft" of the spring.

The driven disk with a spring damper of torsional vibrations is located on the splines of the input shaft of the gearbox between the flywheel and the pressure plate. Two disc friction linings are riveted on both sides to a spring plate, which, in turn, is riveted to one of the two damper plates.

The spring plate has a wavy shape. When the clutch is engaged, the friction linings compress the spring plate, which contributes to a smoother engagement of the clutch.

A disk hub is installed between the damper plates. Damper springs are installed in the grooves of the hub and damper plates.

The damper plates are connected by bearing pins. In the disc hub, opposite the support pins, there are cutouts that allow the hub to rotate within certain limits relative to the damper plates, while compressing the damper springs.

This allows you to reduce dynamic loads in the transmission when starting the car and when shifting gears. An idle damper is located on the hub of the driven disk in a plastic case, which serves to dampen torsional vibrations and eliminate knocks in the gearbox when the engine is idling.

The driven disk is replaced when the axial runout of the linings is more than 0.5 mm, oiling, cracking, scuffing or uneven wear of the linings, weakening of the rivet joints, and also if the distance between the working surface of the lining and the head of the rivet is less than 0.3 mm.

Clutch release drive? hydraulic. The force in it from the pedal to the clutch release bearing is transmitted through the working fluid. The hydraulic drive consists of the main and working clutch cylinders connected by a pipeline. The reservoir of the hydraulic drive of the clutch is common with the reservoir of the hydraulic drive of the brake system.

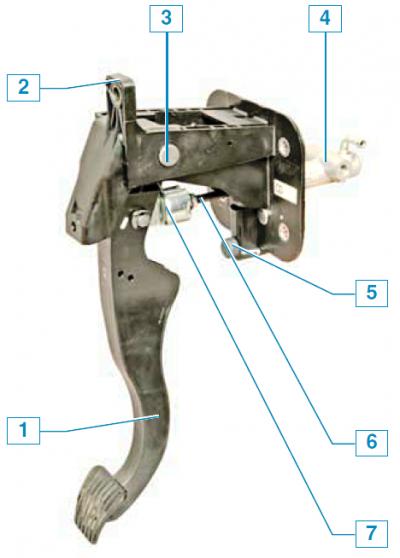

Elements of the clutch pedal assembly: 1 - pedal; 2 - bracket; 3 - pedal axis; 4 - clutch master cylinder; 5 - pedal stroke limiter; 6 - pusher rod; 7 - pusher fork

The clutch pedal is mounted on the axis of the pedal assembly bracket. The pedal is connected by a pusher to the clutch master cylinder piston. To eliminate squeaks in the pedal assembly, the pusher fork is connected to the rod by an elastic connection - through a damper.

Clutch master cylinder assembly with pusher

Pusher fork elements: fork; rubber damper; pad; screw; plastic cup

The working cylinder of the hydraulic drive is made as a single unit with the clutch release bearing and is located inside the clutch housing. The slave cylinder body is attached to the clutch housing.

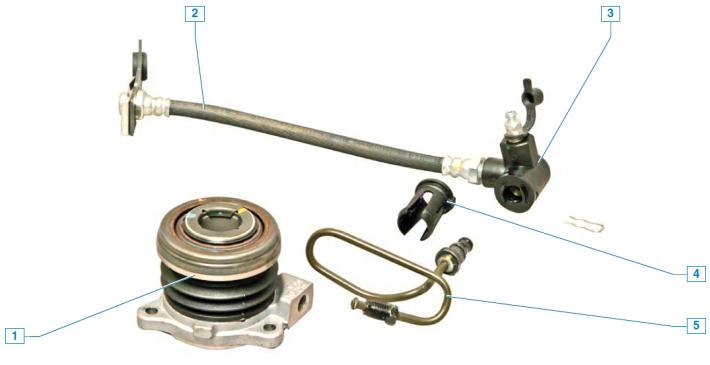

Elements of the hydraulic clutch: 1 - assembly of the working cylinder and clutch release bearing; 2 - hose; 3 - adapter; 4 - sleeve; 5 - tube

The piston of the working cylinder is connected to a bearing that can move along the input shaft of the gearbox. Spring (covered with a rubber corrugated cover), located between the cylinder body and the bearing race, constantly presses the bearing against the clutch "basket" diaphragm spring.

Clutch disengagement occurs as follows. When the pedal is pressed in the hydraulic system of the drive, the pressure of the working fluid is created, as a result of which the piston of the working cylinder moves the clutch release bearing along the axis of the gearbox input shaft.

The bearing presses on the petals of the "basket" diaphragm spring.

The spring, deforming, ceases to press the "basket" pressure plate against the flywheel. In this case, the driven disk moves away from the flywheel, as a result of which the engine crankshaft and the gearbox input shaft can rotate independently of each other. When the clutch pedal is released, the bearing returns to its original position, while the diaphragm spring again begins to press on the pressure plate, which, in turn, presses the driven disc against the flywheel - as a result, the transmission of torque resumes.