To check the health of the hydraulic pusher..

... with a screwdriver we press on it, trying to press the pusher into the socket of the cylinder head (at the same time, the corresponding camshaft cam must be turned to the pusher with the "back of the head", i.e., do not put pressure on it).

In this case, a serviceable hydraulic pusher will move in the cylinder head socket with considerable force, compressing the valve spring. If, with a slight effort, the hydraulic pusher itself is pressed through, it must be replaced.

To do this, remove the camshaft pulley (see Camshaft oil seal replacement).

Head "10" evenly, in several steps (half a turn per pass) we turn off two bolts of fastening of each of five covers of bearings of a camshaft.

Remove the camshaft bearing caps.

First (extreme right) The lid is different from other lids.

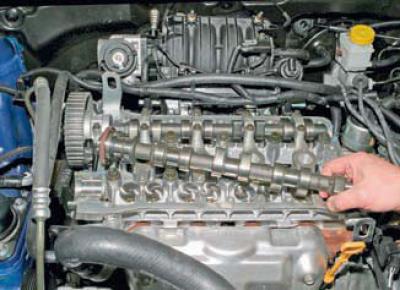

We take out the exhaust camshaft from the beds of the cylinder head.

If necessary, similarly dismantle the intake camshaft.

Remove the seal from the shaft neck.

We take out the hydraulic pusher from the socket in the cylinder head.

Before installation, we lower the new hydraulic pusher into a container with clean engine oil and press the plunger pair of the hydraulic pusher several times until air bubbles stop coming out of the hole in its groove.

Install the hydraulic pusher in reverse order. Other hydropushers are replaced similarly.

Before laying the camshaft in the bed of the cylinder head, apply a thin layer of engine oil to the bearing necks and cams of the shaft.

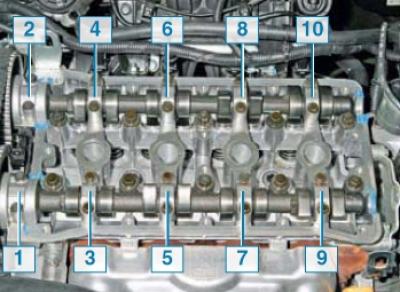

Having laid the shaft, we install the shaft bearing caps in accordance with the order of their designation in the cylinder head and the markings on the outer surface of the caps.

The order of designation of covers in the cylinder head

Cover marking No. 1.

Cap marking No. 6 (in the photo on the left) and No. 9 camshaft bearings.

We wrap the bolts of the shaft bearing caps and evenly, moving from cap to cap, in several stages (gradually increasing the tightening torque) tighten the bolts to the required torque (see Tightening torques for critical threaded connections).

Pressing the camshaft seal (see Camshaft oil seal replacement).

Further assembly is carried out in reverse order.

After replacing the hydraulic pusher, the engine may run with increased noise for a short time until the hydraulic pusher is pumped.