Using a screwdriver, we squeeze out four latches in turn..

... and remove the plastic casing.

Using the E4 head, unscrew the three screws securing the brush holder and the rectifier unit.

Remove the brush holder with voltage regulator.

Solder the stator winding leads from the rectifier block leads.

Remove the rectifier.

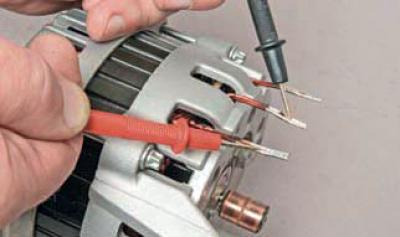

To check the rotor winding for open and short circuit..

... we connect the ohmmeter probes to the slip rings.

We measure the resistance of the rotor winding, which should be in the range of 1.7–2.3 ohms. If the resistance is less than specified, then part of the turns of the rotor winding is closed to each other, if the resistance is very large (tends to infinity), then there is a break in the rotor windings. In both cases, the generator rotor must be replaced.

To check if the rotor windings are shorted to ground..

... we connect the ohmmeter probes to the rotor shaft and alternately to the slip rings.

The measured resistance must be very large (strive for infinity). If the ohmmeter shows a small resistance, then the rotor windings are shorted to ground. In this case, the generator rotor must be replaced.

To check the stator windings for an open..

... with an ohmmeter we alternately measure the resistance between all the terminals of the windings.

If the measured resistance tends to infinity, then there is an open in the stator windings and the generator stator must be replaced.

To check if the stator windings are shorted to ground..

... we connect the ohmmeter probes to the generator case and in turn to each output of the windings.

The measured resistance must be very large (strive for infinity). If the ohmmeter shows a small resistance, then the stator windings are shorted to ground. In this case, the generator stator must be replaced.

To check the "positive" diodes of the rectifier unit..

... connect the red probe ("plus") ohmmeter to the "positive" plate of the block, and black ("minus") - to the output of the "positive" diode.

We measure the resistance. Then we change the probes of the ohmmeter in places and measure the resistance again. If the resistance is the same in both cases, then the diode is faulty and the rectifier unit must be replaced.

Similarly, we check the other two diode circuits of the rectifier.

To check the "negative" diodes of the rectifier unit..

... connect the red probe ("plus") ohmmeter to the "negative" plate of the block, and black ("minus") - to the output of the "negative" diode.

We measure the resistance. We change the probes of the ohmmeter in places and measure the resistance again. If the ohmmeter readings are the same in both cases, then the diode is faulty and the rectifier unit must be replaced. Similarly, we check the other two diode circuits of the rectifier.

Voltage regulator test circuit.

To check the voltage regulator, connect a test lamp (1-5W, 12V) between brushes.

We supply a voltage of 12 V from a DC source: "+" to the "L" terminal and at the same time to the "B+" output of the voltage regulator, "-" to the second output of the voltage regulator. The lamp should light up. When a voltage of 15–16 V is applied, the lamp should go out.

If the lamp is lit in both cases, then the regulator is damaged; if it does not light up, there is an open in the circuit or the contact between the brushes and the regulator leads is broken. In both cases, the regulator should be replaced.

We assemble the generator in reverse order.