When the engine is off, the switched on consumers are powered by the battery, and after the engine is started, from the generator.

When the generator is running, the battery is charged.

The car is equipped with a maintenance-free lead-acid starter battery with a capacity of 55 Ah.

The generator is a synchronous alternating current electric machine with a built-in rectifier unit and voltage regulator.

The alternator pulley is driven by a V-ribbed belt from the accessory drive pulley.

The stator and generator covers are tightened with four screws. The rotor shaft rotates in ball bearings installed in the generator covers. Sealed bearings, lubricated in them, designed for the entire service life of the generator. The rear bearing is pressed onto the rotor shaft, and is installed in the cover with a slight interference fit. The front bearing is pressed into the front cover, and the bearing has a sliding fit on the rotor shaft.

The generator stator contains a three-phase winding. The second ends of the phase windings are soldered to the terminals of the rectifier unit, which consists of six silicon diodes (valves) - three "positive" and three "negative", pressed into two horseshoe-shaped aluminum plates-holders in accordance with the polarity (positive and negative on different plates). The rectifier unit is fixed on the rear cover of the generator.

The excitation winding is located on the generator rotor, and its leads are soldered to two copper slip rings on the rotor shaft. Power is supplied to the excitation winding through two brushes that are installed in the brush holder. The brush holder and voltage regulator are mounted on the rear cover of the generator.

The voltage regulator is a non-separable unit; if it fails, it is replaced.

The "minus" of the battery should always be connected to the "mass" of the car, and the "plus" - to the output of the generator. Reverse connection will lead to a breakdown of the generator rectifier unit diodes.

When the generator is running, the battery should not be disconnected, as the resulting voltage surges can damage the electronic components of the circuit.

The starter is a four-brush DC electric motor with permanent magnet excitation, with a planetary gear, a freewheel roller clutch and a two-winding traction relay.

Permanent magnets are attached to the steel body of the starter. The body and covers of the starter are tightened with two bolts. The armature shaft rotates in plain bearings. The torque from the armature shaft is transmitted to the drive shaft through a planetary gearbox, consisting of a central and crown (with internal gear) gears and three satellites on the carrier (drive shaft).

Freewheel mounted on the drive shaft (overrunning clutch) gear.

The traction relay is used to engage the drive gear with the ring gear of the flywheel of the crankshaft of the engine and turn on the power to the starter motor. When the ignition key is turned to the START position, voltage is applied to both windings of the traction relay (pulling and holding). The relay armature retracts and moves the drive lever, which moves the freewheel with the drive gear along the splines of the drive shaft, engaging the gear with the flywheel crown. In this case, the retracting winding is turned off and the contacts of the traction relay are closed, including the starter motor. After the key is returned to the ON position, the holding winding of the traction relay is de-energized and the relay armature returns to its original position under the action of the spring - the relay contacts open and the drive gear disengages from the flywheel.

The defective traction relay is replaced. A starter drive malfunction is detected during inspection after disassembling the starter.

The lighting and signaling system includes two headlights; fog lights; side direction indicators; rear lights; license plate lights; additional brake signal; ceiling lamps for interior and luggage compartment lighting; a sound signal, as well as switches for all these consumers.

Block headlight of cars with sedan and station wagon bodies

Block headlight of a car with a hatchback body

The block headlights of cars with a hatchback body differ from the block headlights of cars with sedan and station wagon bodies.

The headlights of cars with sedan and station wagon bodies are equipped with: halogen low beam lamp, halogen high beam lamp, side light lamp, direction indicator lamp (orange color) and executive mechanism (gear motor) headlight beam direction controller. Unlike them, a double-filament halogen high / low beam lamp is installed in the hatchback headlight.

Fog lights are installed in the front bumper.

The fog lamp has a halogen lamp, the direction of the light beam of which is adjusted by a screw.

The rear lights of cars with all three types of bodies are different from each other.

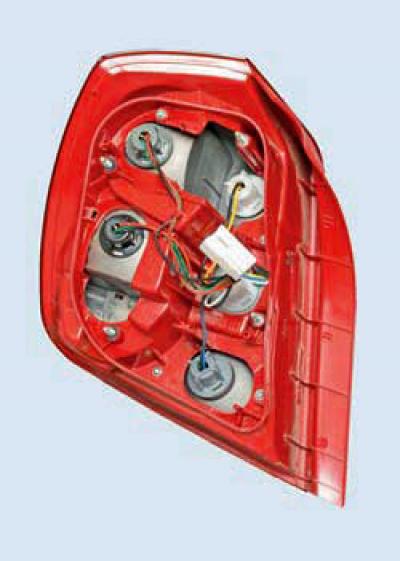

sedan tail light

hatchback tail light

station wagon tail light

The following lamps are installed in the rear lamp: two-filament brake signal and side light; direction indicator (orange color); fog light; reverse light. Lanterns on cars with sedan and station wagon bodies are installed on the rear fenders. The taillights of a hatchback vehicle consist of two parts: one is mounted on the rear wing, the other is on the tailgate. The sedan's headlight has two double-filament bulbs (21/5 Tue): one is a brake signal and side light, the second is side light, but it only turns on the 5 W thread when the side light is turned on.

The car is equipped with driver and front passenger airbags. The driver's airbag is located on the steering wheel. The front passenger airbag is installed in the instrument panel.

Some cars are equipped with side airbags for the driver and front passenger, which are installed in the backs of the front seats on the side of the doors. The airbag control unit is located in the passenger compartment under the lining of the floor tunnel between the front seats. This unit also controls the driver's and front passenger's seat belt pretensioners.

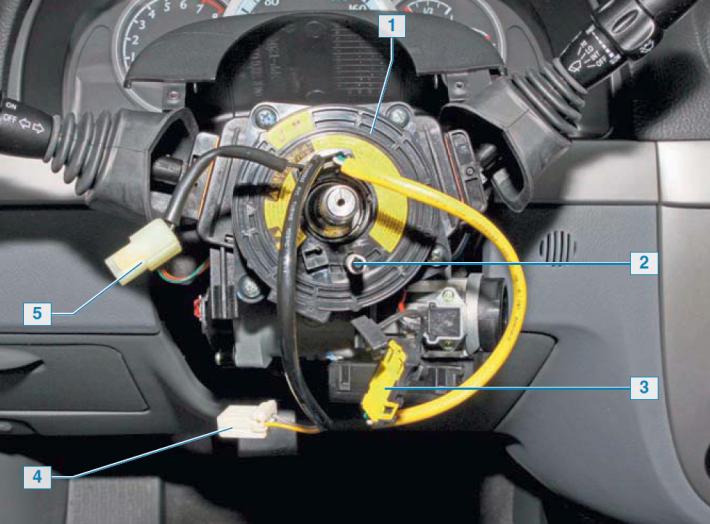

For electrically connecting the airbag, horn switches and audio head unit control unit to the instrument panel wiring harness instead of the conventional sliding contact (to avoid sparking and unintentional airbag deployment) a drum device with a spiral cable was used, operating on the principle of a tape measure.

Drum unit with spiral cable: 1 - body of the drum device; 2 - leash of the drum device; 3 — a block of wires of an airbag; 4 - block of wires of the control unit of the head unit of the sound reproduction system; 5 — a block of wires of switches of a sound signal.

The drum unit is attached to the steering column switch connector. In the cylindrical plastic case of the device, several turns of a metal-plastic tape are spirally laid, which is an electrical conductor. One end of the tape, through wires with pads, is connected to the instrument panel wiring harness. The other end of the tape is connected by wires to the blocks with an airbag, the control unit of the head unit of the sound reproduction system and the horn switches. The drum leash enters the hole in the steering wheel hub. During rotation, the wheel by the leash turns the drum, and with it the tape, which is located in a cylindrical housing either on a larger or smaller radius.

From its middle position, the drum can rotate in each direction until it stops by 3.25 turns. This prevents the tape from breaking when the steering wheel is rotated from neutral to full stop in each direction.

Before installing the steering wheel, it is necessary to set the drum of the device to the middle position, while the leash must be located below.

Locks of all doors are blocked by electric drives. Removal of electric door locks is shown in Ch. Body.

Depending on the configuration, the car may be equipped with power windows for the front doors only, or for all doors.

Removal of power windows is shown in Sec. Body.

The power window motor-reducer consists of a worm gear and a reversible DC motor. A drum with a cable is installed on the output shaft of the gearbox. A slider is fixed on the cable, moving along the guide. Glass holders are attached to the slider with two screws.

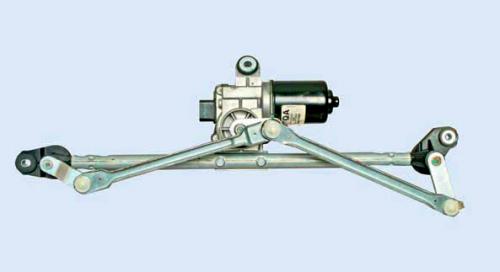

The windshield wiper is installed under the windshield trim.

The electric motor of the cleaner is three-brush, two-speed, with excitation from permanent magnets.

The windshield washer consists of a polyethylene tank with an electric pump, nozzles on the hood and connecting hoses. The washer reservoir is located behind the left front fender. The filler neck of the tank is displayed in the engine compartment.

Cars with hatchback and station wagon bodies are equipped with a tailgate glass cleaner and washer. The cleaner is installed inside the tailgate. The electric motor of the cleaner is two-brush with excitation from permanent magnets.

The washer nozzle is mounted on the tailgate and is connected by a hose to the windshield washer pump, which supplies liquid to it. The washer pump on the hatchback and station wagon is reversible, when the pump motor shaft rotates in one direction, the liquid from the reservoir is supplied to the windshield, and when rotated in the other direction, the liquid is supplied to the tailgate glass.

The vehicle is equipped with a battery discharge protection system. If you remove the key from the ignition switch and open the driver's door while the headlights or taillights are on, the headlights and sidelights will turn off automatically. In this case, only the interior lighting does not turn off. The protection system is controlled by a block located on the left under the instrument panel.

For some cars, the manufacturer installs a regular car anti-theft system. The anti-theft system control unit is installed under the floor tunnel lining. The siren is installed in the engine compartment.

The anti-theft system also includes sensors for opening the hood, doors and trunk. In the event of an unauthorized entry into the vehicle interior or engine start, the anti-theft system turns on the siren and all direction indicators for 28 seconds.

Most electrical circuits are protected by fuses. Powerful Consumers (rear window heating element, engine cooling fan, power windows and others) connected via a relay.

The fuses and most of the relays are installed in two mounting blocks, one of which is located on the left, in the engine compartment, and the second in the instrument panel. This block is closed by a cover in the left end of the instrument panel.

Fuses of the mounting block in the engine compartment

| Fuse designation (rated current, A) | Protected elements |

| Ef1 (30) | Fuse circuits F13-F15 and F21-F24 |

| Ef2 (60) | ABS control unit circuits |

| Ef3 (30) | heater fan |

| Ef4 (30) | ignition switch (starter, fuse circuits F5-F8) |

| Ef5 (30) | ignition switch (fuse circuits F1-F4, F9-F12, F17-F19) |

| Ef6 (20) | Cooling Fan Low Speed Relay Power Circuit |

| Ef7 (30) | Rear window heating element |

| Ef8 (30) | Cooling Fan High Speed Relay Power Circuit |

| Ef9 (20) | Power window motors for right front and rear doors |

| Ef10 (15) | Ignition coil, ECU, EGR valve |

| Ef11 (10) | ECU, main relay (ECU Sirius D4) |

| Ef12 (25) | Headlights, position light relay coil |

| Ef13 (15) | Brake light switch, brake lights |

| Ef14 (20) | Power window motor, left front door |

| Ef1 5 (15) | High Beam Lamps |

| Ef16 (15) | Horn, car alarm siren, hood open sensor |

| Ef17 (10) | A/C Compressor Clutch |

| Ef18 (15) | Fuel pump |

| Ef19 (15) | Instrument cluster, interior and trunk lamps, immobilizer status indicator, warning signal, control unit for folding exterior mirrors |

| Ef20 (10) | Low beam lamp, left headlight |

| Ef21 (15) | Oxygen sensors, canister purge valve, phase sensor, ECU (Sirius D4), cooling fan low speed relay coil, cooling fan high speed relay coil, cooling fan control relay coil |

| Ef22 (15) | Injectors, EGR Valve, Fuel Pump Relay Coil (ECU HV-240) |

| Ef23 (10) | License plate lamps, position lamp in the left headlight, position lamp in the left rear lamp, warning signal |

| Ef24 (15) | Fog lights |

| Ef25 (10) | Elements of heating of external rear-view mirrors |

| Ef26 (15) | Central lock control unit |

| Ef27 (10) | Right low beam lamp |

| Ef28 (10) | Position light lamp in the right headlight, position light lamp in the right tail lamp, instrument illumination dimmer, clock, instrument cluster illumination, illumination of the ventilation, heating and air conditioning control unit, illumination of the automatic air conditioning control unit, ashtray illumination, illumination of the headlight beam direction control, head unit illumination, HOLD mode switch illumination, hazard warning switch illumination |

Relay mounting block in the engine compartment

| Designation | Name | Switched circuits |

| K1 | side light relay | Side light bulbs in headlights, side light bulbs in taillights, backlight bulbs for instrument cluster and controls |

| K2 | Horn relay | Sound signal |

| K3 | Main relay of the engine management system | Injectors, oxygen sensors, phase sensor, canister purge valve, fuel pump relay coil, cooling fan high speed relay, cooling fan low speed relay, cooling fan control relay |

| K4 | headlight relay | Headlight bulbs |

| K5 | Fog lamp relay | Fog lamps |

| Kb | A/C compressor relay | AC compressor electromagnetic clutch |

| K7 | Fuel pump relay and ignition coil | Fuel pump motor and ignition coil |

| K8 | Power window relay | Power window motors |

| K9 | Cooling Fan Low Speed Relay | Cooling fan motor |

| K10 | Heated rear window relay | Rear window heating element |

| K11 | Cooling fan high speed relay | Cooling fan motor |