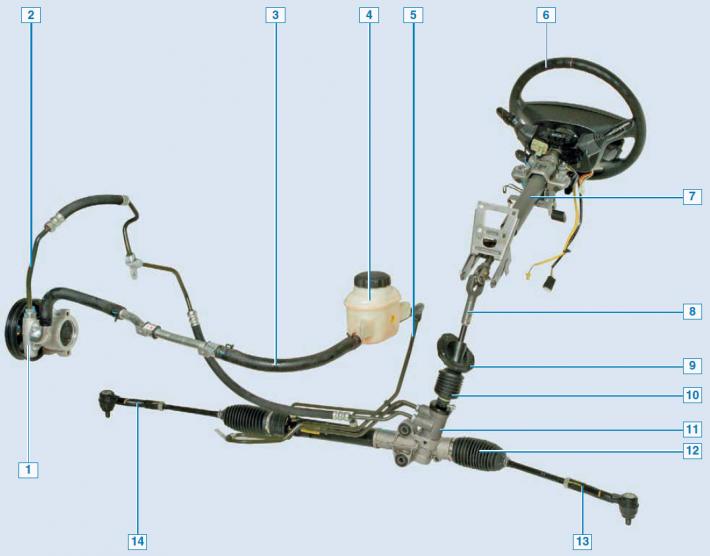

Steering elements: 1 - power steering pump; 2 - discharge line; 3 - filling line; 4 — a reservoir of the hydraulic booster of a steering; 5 - drain line; 6 - steering wheel; 7 - steering column; 8 - intermediate steering shaft; 9 - intermediate shaft seal; 10 - anther hinge; 11 — steering mechanism; 12 — a cover of the steering mechanism; 13 - left tie rod; 14 - right steering rod.

The steering of the car consists of a steering wheel with a built-in airbag, a safety steering column, an intermediate shaft, a steering gear with rods and tips, a pump and a power steering reservoir with pipelines.

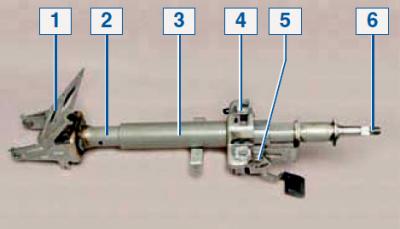

The steering column is attached to the bulkhead with two nuts (above) and two bolts (from below), as well as to the instrument panel frame? two nuts.

Steering column: 1 - bracket for fastening the column to the front panel; 2 - inner pipe; 3 - outer pipe; 4 — an arm of fastening of a column to a framework of the panel of devices; 5 - column tilt adjustment mechanism; 6 - steering shaft.

On the splines of the steering shaft located in the column, a steering wheel is installed, fixed with a central nut.

The steering shaft, through an intermediate shaft having two cardan joints, is connected to the steering gear shaft.

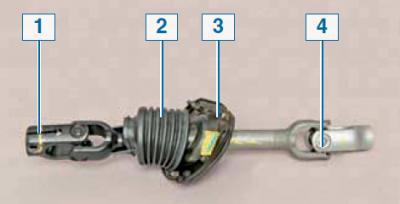

intermediate shaft: 1 - lower cardan joint; 2 - anther; 3 - sealant; 4 - upper cardan joint.

The design of the intermediate steering shaft allows you to change (shorten) its length in a car collision.

In the event of an accident, two plastic pins connecting the parts of the shaft are cut off.

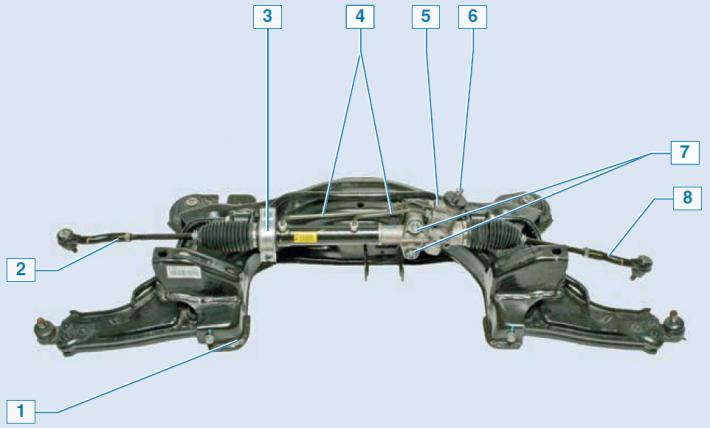

The steering mechanism is of the rack and pinion type. The crankcase of the mechanism is attached to the front suspension subframe with a bolt and stud (with nut), passing through rubber-metal bushings inserted into the crankcase holes, and the crankcase pipe - with a bracket through the rubber cushion. The housings of the steering rod joints are screwed into the threaded holes of the ends of the rail. Tips are screwed onto the outer threaded ends of the steering rods, the ball joints of which are connected to the steering knuckles of the steered wheels.

Steering gear assembly with front suspension subframe: 1 - subframe; 2 — a tip of the right steering draft; 3 - bracket for fastening the crankcase pipe; 4 - connecting tubes of the hydraulic booster; 5 - crankcase mechanism; 6 - pinion shaft; 7 - bolt and nut with crankcase mounting stud; 8 — a tip of the left steering draft.

The length of the tie rod assembly with the tip is changed by rotating the rod with the lock nut loosened. This allows you to adjust the convergence of the steered wheels of the car.

Tie rod with tip: 1 - tip; 2 - anther; 3 — a finger of a spherical hinge of a tip; 4 - locknut; 5 - thrust; 6 - thrust hinge.

The spherical joints of the rod end and the rod itself have a non-separable design and do not require replenishment of the lubricant supply, which is embedded inside for the entire service life.

The hydraulic booster of a steering is built in the steering mechanism.

The hydraulic booster system also includes: a tank, a vane pump, pipes for drain, discharge and filling lines.

The supply of power steering fluid is located in a reservoir located in the engine compartment and fixed on the wall of the battery shelf. To control the liquid level, the translucent body of the tank is marked with MIN and MAX marks.

Power steering reservoir.

The power steering pump is mounted on a common bracket of the engine block, to which the auxiliary drive belt tensioner and the air conditioning compressor are also attached. The pump pulley is driven by a V-ribbed belt from the engine crankshaft pulley.

Power steering pump.

The working fluid from the tank is taken by the pump and supplied under high pressure to the switchgear (distributor), located in the steering gear housing and mechanically connected to the steering shaft.

A hydraulic cylinder piston is fixed on the gear rack of the steering mechanism. When the steering wheel is turned, the switchgear connects one of the hydraulic cylinder chambers to the pump discharge line, and the other chamber to the drain line.

At the same time, the piston of the hydraulic cylinder, due to the pressure difference of the working fluid, moves the rack to the left or right and, through the steering rods and steering knuckle levers, turns the steered wheels of the car. If the hydraulic booster fails, the ability to drive the car remains, but the effort on the steering wheel increases.

On some vehicles, a power steering system is used, which provides variable gain depending on the speed of the vehicle.

At low speeds, the system provides maximum power for easier turning and parking maneuvers.

At high speed, the steering assistance is reduced to improve the vehicle's directional stability. The system performs these tasks by changing the flow of fluid through the pump. Steering control electronics (mounted on the instrument panel bracket, under the glove box) receives signals: about the speed of the car - from the engine control system unit; about the steering angle (for calculating the angular velocity of the steering wheel) - from the sensor located at the bottom of the steering shaft. After processing the signals, the unit issues a control signal to the pump solenoid needle valve, which regulates the flow of the working fluid through the pump.

Location of the power steering pump solenoid valve.