- elevated (compared to usual) noise:

- difficult gear shifting;

- spontaneous disengagement or fuzzy engagement of gears;

- oil leakage through seals and gaskets.

In addition, the gearbox is removed to replace the clutch, flywheel and rear engine crankshaft oil seal.

An automatic transmission is removed for almost the same reasons as a manual transmission, except for the need to replace the clutch and flywheel, which in this case are absent. Removal and installation techniques for manual and automatic transmissions are almost the same and are described using the example of a manual transmission. The difference lies in the design of the gearbox control drive.

Helpful Hints: The work of removing and installing the gearbox is very laborious, so be sure to first make sure that its malfunctions are not caused by other reasons (insufficient oil level, defects in the clutch drive, loosening of the gearbox, etc.).

The gearbox is quite heavy and its shape is not comfortable to hold, so we recommend removing the gearbox with an assistant.

You will need: keys «at 12», «at 14», «at 19», pliers.

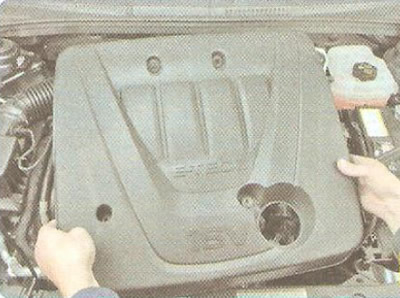

1. Remove the decorative engine cover (see «Removal and installation of a decorative casing of the engine»).

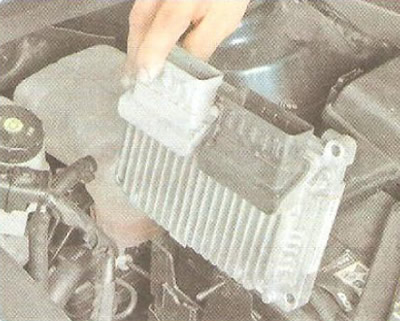

2. Remove the electronic engine control unit (see «Removal and installation of the electronic engine control unit»).

3. Remove the fuse and relay mounting block (see «Removal and installation of mounting blocks»).

4. Remove the battery (see «Removing and installing the battery»).

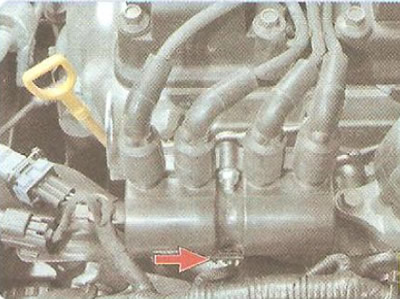

5. Disconnect the wiring harness connector from the ignition coil leads.

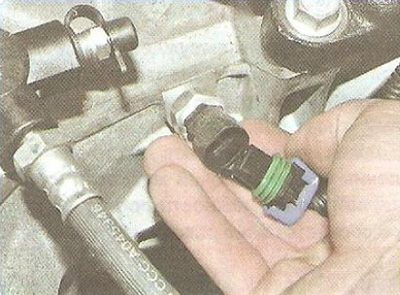

6. Disconnect the wiring harness connectors for the crankshaft position sensor and the oxygen concentration sensor. Remove the pads from the bracket on the gearbox by squeezing the antennae of their holders.

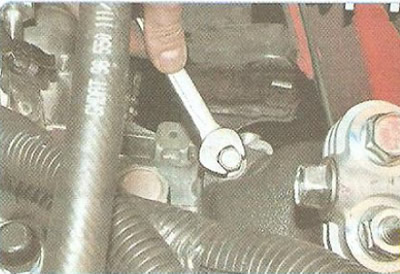

7. Squeezing the fasteners, disconnect the wiring harness pads from the speed sensor...

8.... and reverse light switch.

9. Drain coolant (see «Coolant replacement»).

10. Drain the gearbox oil (see «Checking the level, topping up and changing the oil in a manual transmission»).

11. Squeeze the antennae of the clamp that secures the outlet hose of the heater radiator to the distribution pipe, slide the clamp along the hose...

12.... and disconnect the hose from the pipe.

13. Squeeze the antennae of the clamp that secures the outlet hose of the radiator of the cooling system to the distribution pipe, slide the clamp along the hose...

14.... and disconnect the hose from the pipe.

Note: Coolant radiator hoses must be disconnected from the water distribution pipe to gain access to the upper transmission mounting bolts.

15. Remove the starter (see «Removal and installation of a starter»).

16. Set aside the wiring harness located on the left side of the engine compartment so that it does not interfere with further work.

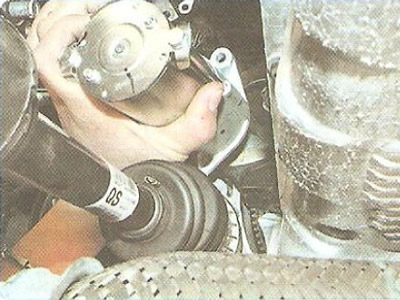

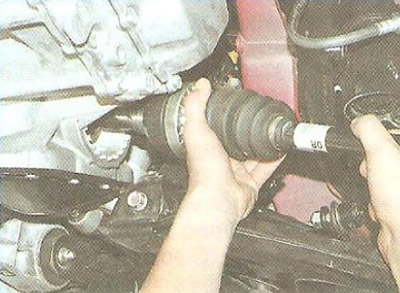

17. Remove the front wheel drives (see «Removal and installation of front wheel drives»).

18. Remove the stopper of the reservoir of the main brake cylinder and pump out, for example, with a large medical syringe, the brake fluid from the section of the reservoir of the main brake cylinder that feeds the clutch release hydraulic drive.

Note: The reservoir shared between the brake and clutch master cylinders consists of three separate sections: two for separate brake circuits and one for the clutch release.

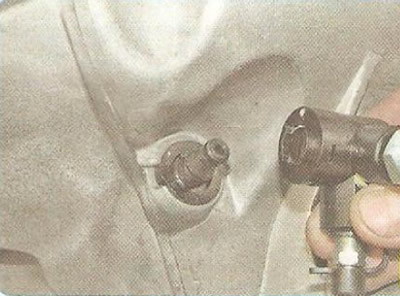

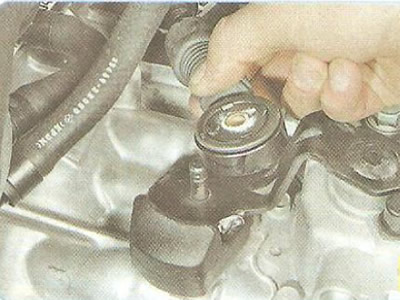

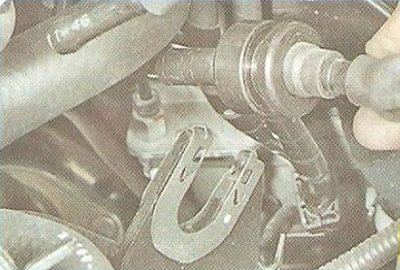

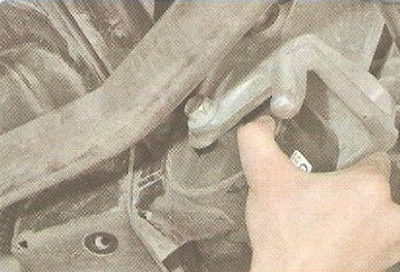

19. Prying off with a screwdriver...

20.... remove the retainer from the hose adapter...

21.... and remove the adapter from the tip of the intermediate tube of the clutch hydraulic actuator.

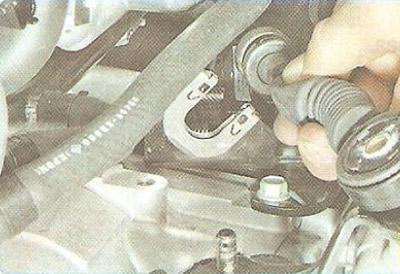

22. Remove the tip of the shift cable from the axle of the gear lever.

23. Take a tip of a cover of a cable from a cut of an arm on a transmission. Move the shift cable to the side.

24. Disconnect the second shift cable in the same way.

25. Take a tip of a cover of a cable from a cut of an arm on a transmission. Move the gear selector cable to the side.

26. Remove the front suspension subframe (see «Removing and installing front suspension subframe»).

27. Support the engine oil sump, using a piece of board as a spacer, and under the gearbox.

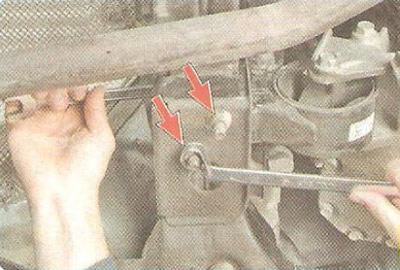

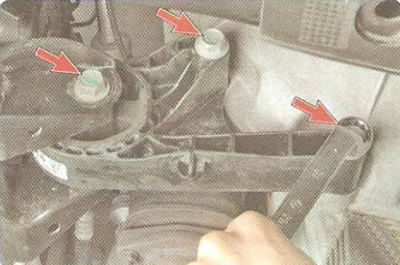

28. Turn away two nuts of bolts of fastening of a support to a subframe of a forward suspension bracket and take bolts up.

29. Turn out three bolts of fastening of an arm of a back support to a transmission case.

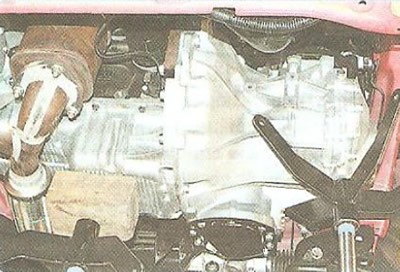

30. Remove the suspension support of the power unit assembly with the bracket moving forward and to the right in the direction of the vehicle.

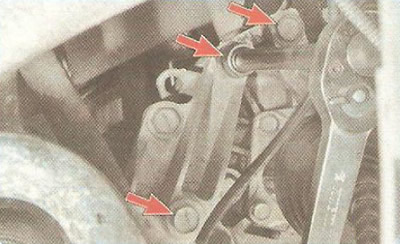

31. Remove the rear bolt..

32.... and two front bolts for fastening the bracket of the left suspension support of the power unit to the gearbox housing.

33. Turn out a bolt of fastening of an arm of the left support of a suspension bracket of the power unit to a pillow of a support and remove an arm.

34. Turn out three bolts of fastening of a forward support of a suspension bracket of the power unit...

35.... and remove the support.

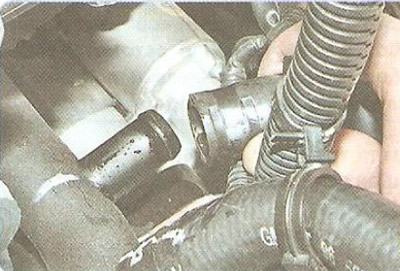

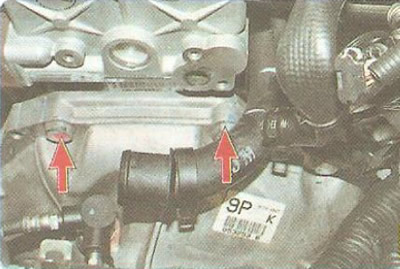

36. Remove the two bolts located at the top of the gearbox housing...

Note: Ignition coil and EGR valve removed for clarity.

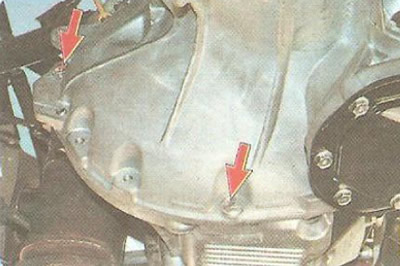

37.... two bolts located at the bottom and left...

38.... a bolt located near the oil filter...

39.... and four bolts securing the gearbox to the engine.

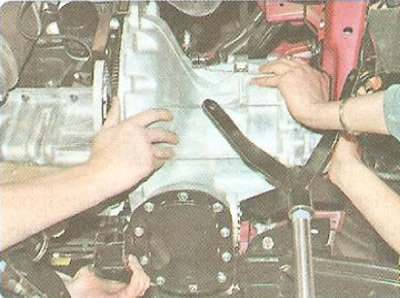

40. Move the gearbox as far back as possible (the input shaft must disengage from the hub of the clutch disc), remove the support from under it and remove the box from the vehicle.

Warning: When removing the gearbox, do not rest the end of the input shaft on the petals of the diaphragm spring, so as not to deform them.

41. Establish a transmission and all removed details and knots in an order, the return to removal.

Helpful Hints: Before installing the gearbox, we recommend lubricating the splines of the input shaft with a thin layer of refractory grease. Check with a special mandrel how the clutch disc is centered (see «Removal and installation of clutch»). Before attaching the front wheel drives to the gearbox, replace the retaining rings on the splined shank of the inner joints with new ones. Otherwise, it is possible to disconnect the drives from the gearbox while driving.

42. Fill the gearbox with oil (see «Checking the level, topping up and changing the oil in a manual transmission»).

43. Fill the working fluid into the reservoir of the main brake cylinder (into its section designed to power the hydraulic clutch release) and bleed the air from the hydraulic clutch release (cm «Bleeding the hydraulic clutch release»).