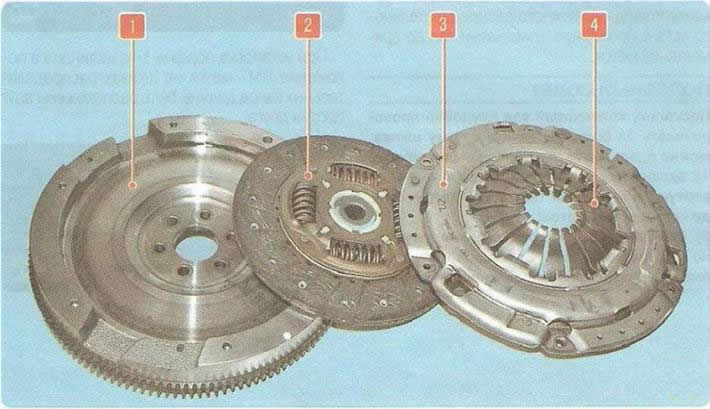

The pressure plate is mounted in a stamped steel casing 3 (pic. 6.1), attached with six bolts to the flywheel 1 of the engine. The driven disk 2 is mounted on the splines of the input shaft of the gearbox and is clamped by a diaphragm spring 4 between the flywheel and the pressure disk.

Pic. 6.1. Clutch: 1 - flywheel; 2 - driven disk; 3 - clutch cover with pressure plate; A - diaphragm spring

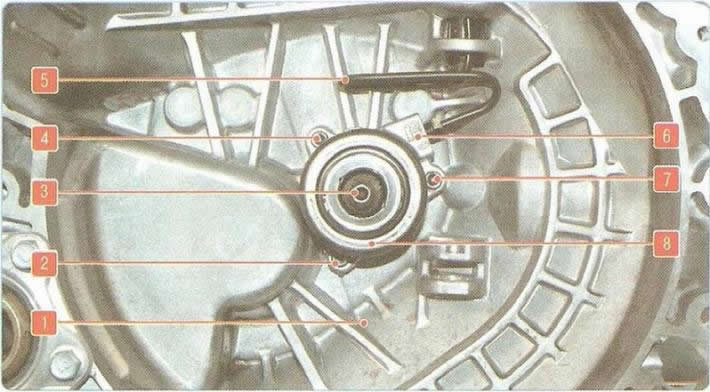

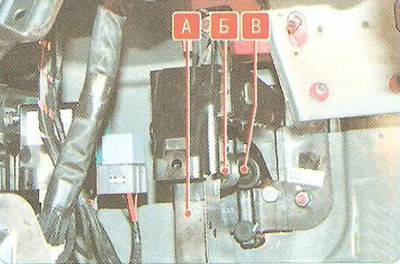

Bearing 8 (pic. 6.2) clutch release is structurally integrated with the working cylinder 6 of the clutch release drive, attached with three bolts to the clutch housing 1.

Pic. 6.2. Bearing and working cylinder of hydraulic clutch release: 1 - clutch housing; 2, 4, 7 - bolts for fastening the working cylinder of the clutch release hydraulic drive; 3 - the input shaft of the gearbox; 5 - intermediate tube of the clutch release hydraulic drive; 6 - working cylinder of the clutch release hydraulic drive; 8 - clutch release bearing

The hydraulic clutch release actuator consists of the following elements...

... the master cylinder installed in the engine compartment...

... working cylinder b (see fig. 6.2), combined with the clutch release bearing...

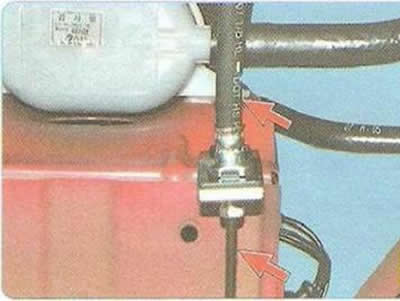

... a pipeline consisting of a tube and a hose (for clarity, the pipeline is shown from below the car)...

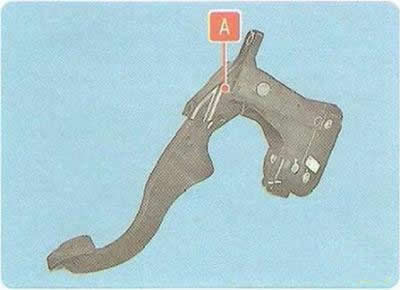

... and a clutch pedal, the bracket of which is attached with nuts to the front end shield of the body. The pedal is returned to its original position by spring A.

The rod B of the master cylinder of the clutch release drive is connected to the pedal A by the pin B inserted into the holes of the pedal and the rod fork and secured against axial movement by a spring retainer.

The master cylinder is connected by a hose to a reservoir mounted on the brake master cylinder (reservoir common to both master cylinders), Clutch release actuator uses brake fluid, Clutch release actuator is adjustable in service.

Helpful Hints: To ensure a long and trouble-free clutch life, do not keep your foot on the clutch pedal all the time. This bad habit is often acquired while learning to drive in driving schools for fear of not having time to turn off the clutch while the car is stopped. In addition to the rapid fatigue of the foot, which is all the time above the pedal, the clutch is, although slightly, but squeezed out, and the driven disk slips and wears out. In addition, although the release bearing is designed to operate in constant rotation mode, when the pedal is pressed a little, it is under increased load, and its life is reduced.

For the same reason, we do not recommend keeping the clutch in the off position for a long time (e.g. in traffic jams). If you do not have to immediately move away, it is better to put the gearbox in neutral and release the pedal.

Clutch slip can be easily determined by the tachometer. If, while driving, with a sharp press on the accelerator pedal, the speed rises sharply, and then drops a little and the car starts to accelerate, the clutch needs to be repaired.