You will need; the same tools as for removing the timing belt, camshaft pulleys (see «Replacing the timing belt and its tension roller»), rear cover of the gas distribution mechanism drive (see «Removal and installation of the oil pump»), cylinder head cover (see «Replacing the cylinder head cover gasket»), as well as the keys «at 12», «at 13», «at 14», torque wrench.

1. Reduce the pressure in the power system if you are working immediately after a trip (see «Reducing the pressure in the power system»).

2. Disconnect the wire from the terminal «minus» battery.

3. Drain coolant (see «Coolant replacement»).

4. Set the piston of the 1st cylinder to the TDC position of the compression stroke (see «Setting the piston of the first cylinder to the TDC position of the compression stroke»).

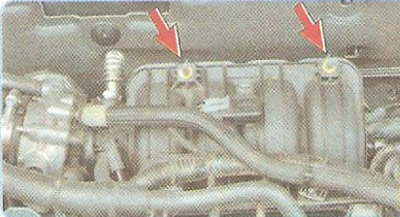

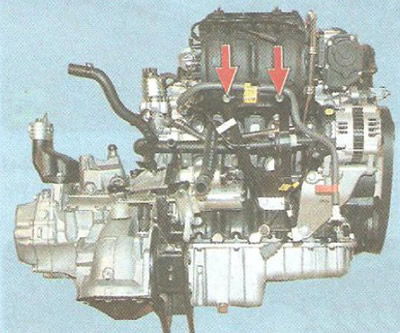

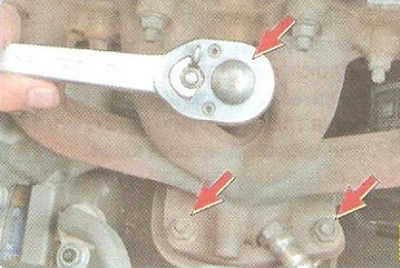

5. Turn out two bolts of fastening of an inlet pipe to a supporting arm.

Note: This is how the bolts for securing the intake pipe to the support bracket are located (for clarity, the power unit is removed).

6. Remove the timing belt and camshaft pulleys (see «Replacing the timing belt and its tension roller»).

7. Remove the rear timing cover (see «Removal and installation of the oil pump»).

8. Disconnect from the throttle assembly the hoses for supplying and draining the coolant, the crankcase ventilation system, the adsorber purge and the air supply pipe (see «Removal and installation of the throttle assembly»).

9. Disconnect the wiring harness connector from the throttle assembly connector (see «Removal and installation of the throttle assembly»).

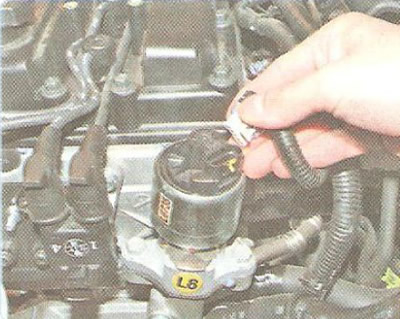

10. Press the plastic retainer of the EGR valve wiring harness block...

11.... and disconnect the block from the valve.

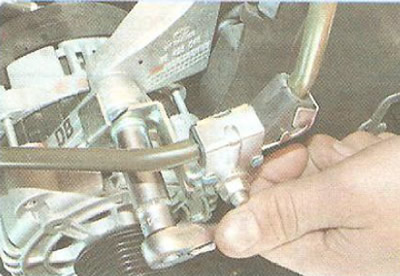

12. Turn away a nut of fastening of an arm of the pipeline of the hydraulic booster of a steering...

13.... move the bracket to the side...

14.... and turn out a hairpin of the top fastening of the generator.

15. Disconnect the wiring harness pads from the injectors, the absolute pressure sensor in the intake pipe and the air temperature sensor in the intake pipe (see «Removal and installation of the fuel rail»).

16. Press the fuel hose end retainers and disconnect the fuel hose from the fuel rail fitting (see «Removal and installation of the fuel rail»).

17. Disconnect from the fittings on the inlet pipe and pneumatic chamber the hoses of the system for changing the length of the inlet pipe (see «Checking and replacing the pneumatic chamber of the inlet pipe damper drive»).

18. Remove the exhaust manifold heat shield (see «Removal and installation of thermal screens»).

19. Disconnect the exhaust manifold and catalytic converter flanges by unscrewing the three flange stud nuts (see «Exhaust manifold replacement»).

20. Remove the cylinder head cover (see «Replacing the cylinder head cover gasket»).

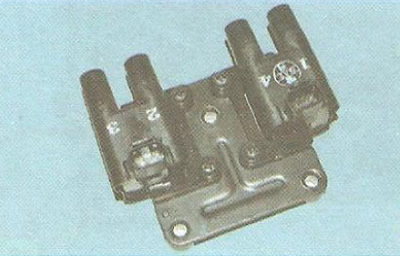

21. Remove the ignition coil (see «Removal and installation of ignition coils»).

22. Disconnect the wiring harness connector from the coolant temperature sensor (see «Checking and replacing sensors and engine control»).

23. Disconnect the coolant hose from the thermostat (see «Removal and installation of the thermostat»).

24. Compress antennae of a collar of a hose of a heater and disconnect a hose from a branch pipe of a heater.

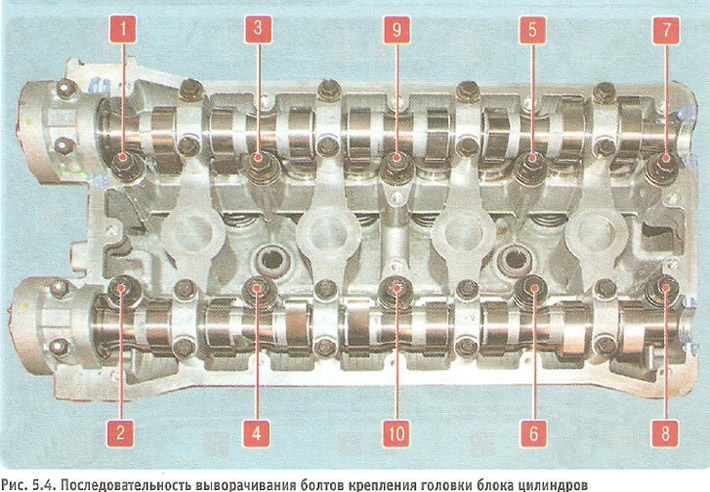

25. Turn out ten bolts of fastening of a head of the block of cylinders in the sequence shown in fig. 5.4, in three steps:

- 1st - unscrew the bolts 1/4 turn;

- 2nd - unscrew the bolts another 3/4 turn;

- 3rd - finally turn out the bolts.

Note: The cylinder head bolts can only be removed when the engine is cold.

26. Remove the bolts...

27.... and remove the cylinder head assembly with the intake pipe and exhaust manifold.

Helpful Hint: Removing the cylinder head is more convenient with an assistant, as it is quite heavy.

28. Remove the cylinder head gasket.

29. Clean mating surfaces (they must be dry and clean) head and cylinder block, remove oil from the threaded holes in the block for the head bolts.

Warning: If the oil is not removed from the threaded holes for the head bolts, cracks may appear in the cylinder block when the bolts are tightened, since the oil is incompressible.

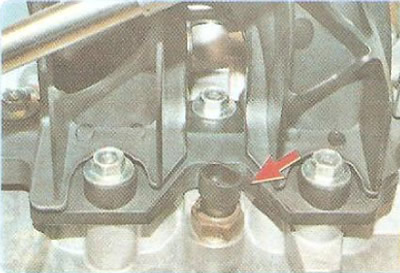

30. Install a new gasket on the cylinder block, centering it over the two guide bushings.

31. Install the cylinder head in the reverse order of removal, taking into account the following:

- be sure to replace the head gasket with a new one, as its reuse is not allowed;

- be sure to replace the head bolts with new ones, as they are deformed when tightened and are not suitable for reuse.

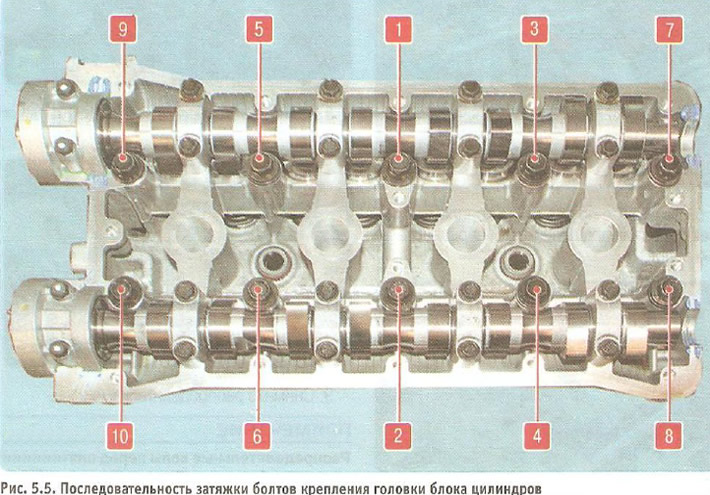

Tighten the bolts on a cold engine in the order shown in fig. 5.5, in four steps:

- 1st - tighten the bolts to a torque of 25 Nm (2.5 kgf·m);

- 2nd and 3rd - each time tighten the bolts at an angle of 70°;

- 4th - tighten the bolts at an angle of 50°;

- replace with a new exhaust manifold gasket that is deformed when the fastening nuts are tightened.

32. Establish the removed details and knots in an order, the return to removal.