The valve stem seals can be replaced without removing the cylinder head from the engine.

You will need: tools needed to remove the timing gear (see «Replacing the timing belt and its tension roller»), rear cover of the gas distribution mechanism drive (see «Removal and installation of the oil pump»), cylinder head cover (see «Replacing the cylinder head cover gasket»), and also tweezers (or magnetized screwdriver) for extracting crackers from the plates of valve springs...

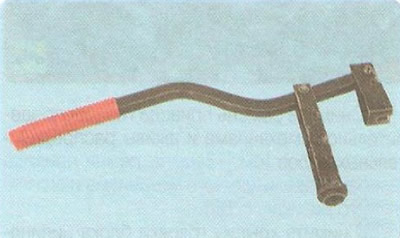

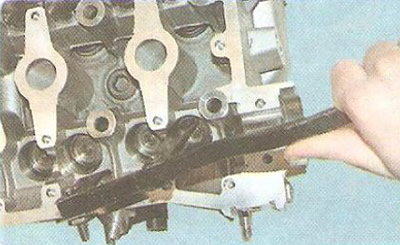

...a valve spring compressor...

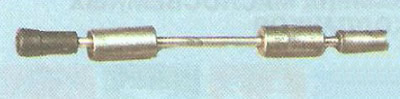

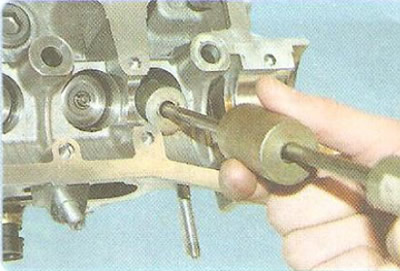

...and an inertial oil seal remover. The puller shown has a mandrel at the other end for push-on caps.

1. Disconnect the wire from the terminal «minus» battery.

2. Remove all spark plugs (see «Replacement and maintenance of spark plugs»).

3. Remove the timing belt and camshaft pulleys (see «Replacing the timing belt and its tension roller»).

4. Remove the cylinder head cover (see «Replacing the cylinder head cover gasket»).

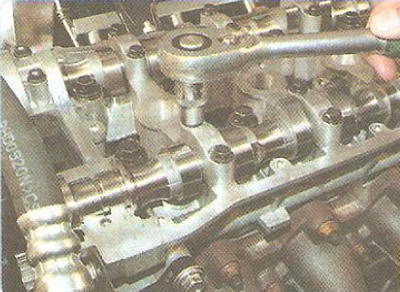

5. Turn out on two bolts of fastening of covers of forward bearings of camshafts...

6.... and remove the covers.

7. Turn out on two bolts of fastening of remaining covers of bearings of camshafts and remove covers.

Note: Remove bearing cap bolts in sequence 2, 6, 10, 1, 5 and 9 (numbers are printed on the lids) in three stages: half a turn, one turn, completely unscrew the bolts. Then gradually turn out crosswise bolts of fastening of covers in sequence 4, 8, 3 and 7.

Warnings: Do not depersonalize the camshaft bearing caps: they are not interchangeable, since the bearing seats are machined complete with caps. If there are no numbers on the covers, mark them in any way possible (for example, punching), to put back in place. In addition to the numbers, the covers are marked with arrows directed towards the gas distribution mechanism drive.

8. Remove the camshaft seals.

9. Remove camshafts.

Note: Before removing the camshafts, mark in any way in order to install them in their original places during assembly.

Warning: For clarity, further operations for replacing valve stem seals are shown on the removed cylinder head. When replacing the valve stem seals on the cylinder head mounted on the engine, to prevent the valves from falling into the cylinder, turn the crankshaft so that the piston of the cylinder whose valves are replacing the caps is at TDC.

10. Remove the hydraulic valve compensator from the socket in the cylinder head, in which you are replacing the valve stem seal.

11. Install the valve spring compressor by screwing the camshaft bearing cap bolt into one of the holes in the head of the block and hooking the tool onto this bolt. Compress the valve spring with the tool.

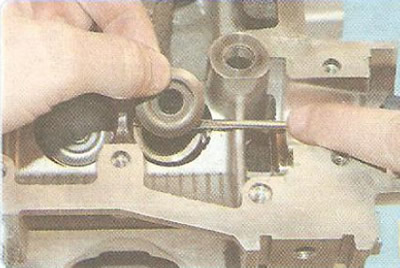

12. Remove two crackers from the upper spring plate using tweezers or a magnetized screwdriver. Then remove the fixture.

13. Prying with a screwdriver, remove the upper spring plate from the socket of the head of the block...

14.... and valve spring.

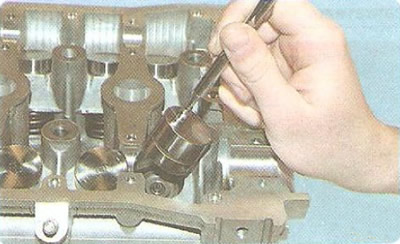

15. Press off the oil scraper cap G of the valve guide. To do this, install the collet of the tool for removing oil seals on the cap and sharply hit the collet bushing with the striker. Then just as sharply strike the striker on the handle of the device...

16.... thus pressing the cap from the sleeve.

17. Remove the cap from the fixture collet. If there is no tool for removing caps, remove them with pliers. In this case, the force must be applied strictly upwards and the caps must not be turned so as not to damage the valve guides.

Warning: Do not remove the cap by prying it on both sides with screwdrivers. The guide sleeve, on which the cap is put on, is made of cermet, and its edge easily breaks off.

18. If the new cap kit includes a plastic mounting sleeve, slide the sleeve onto the valve stem.

19. Lubricate the inner surface of the valve stem seal with engine oil and slide the cap along the valve stem to the guide sleeve.

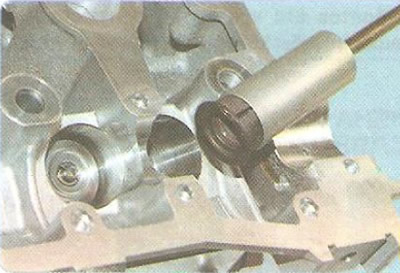

20. Install the mandrel for pressing the cap. With light blows of the striker on the mandrel, press the cap in until it stops.

21. Remove the guide sleeve from the valve stem or put a spring on the cap if it was removed.

22. Install the spring and valve disc in the reverse order of removal. Install the crackers with the tool so that they fit into the grooves of the valve stem. After installing the crackers, hit the end of the valve with a hammer through the metal rod so that the crackers sit in place.

Warning: If the skewed cotters remain unsecured, then when starting the engine «cracked» the valve will fall into the cylinder, resulting in a serious engine failure.

23. Install the hydraulic compensator.

24. Similarly, replace the valve stem seals of the remaining valves.

Helpful Hint: Install the front camshaft bearing caps with sealant to prevent oil from seeping through the junction of the cap and bearing bed.

Note: Install the camshaft seals after installing the front camshaft bearing caps. Methods for installing oil seals are described in subsection «Replacing camshaft seals».