The hydraulic compensators of the F16D and F18D engines, made in the form of cylindrical pushers located between the camshaft and the valves, combine two functions: transferring force from the camshaft to the valves and eliminating gaps in their drive.

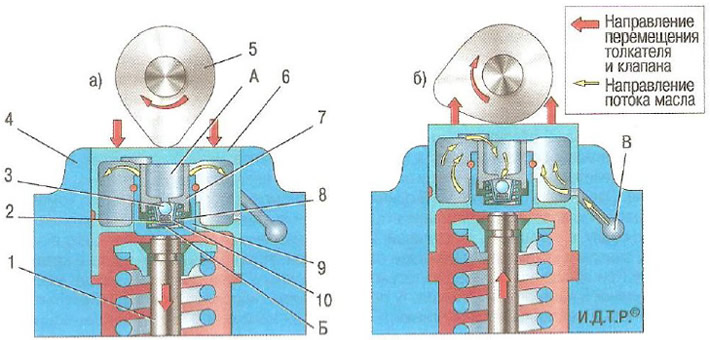

The operation of the hydraulic compensator is based on the principle of incompressibility of engine oil, which constantly fills the internal cavity of the hydraulic compensator during engine operation and moves its plunger when a gap appears in the valve drive. This ensures constant contact of the pusher (valve actuator lever) with camshaft cam without clearance. This eliminates the need to adjust the valves during maintenance. The principle of operation of the hydraulic compensator is shown in fig. 5.8. Oil under pressure necessary for the operation of the hydraulic compensator is supplied to its internal cavities A and B from channel C of the engine lubrication system through a side hole in the pusher 6, made in the annular groove of its cylindrical surface. When the valve is closed 1 pusher 6 (through plunger 7) and sleeve 9 by the expanding force of the spring 8 are pressed respectively to the cam 5 of the camshaft and the end of the valve stem. The pressure in cavities A and B is the same, the check valve 3 of the hydraulic compensator is pressed against the seat in the plunger 7 by the spring 2. At the same time, there are no gaps in the valve mechanism. When the camshaft rotates, the cam 5 runs on the pusher 6, moving it and the associated plunger 7. The movement of the plunger 7 in the sleeve 9 leads to a sharp increase in pressure in the cavity B. sleeve 9 moves in one piece and opens valve 1. With further rotation of the camshaft, cam 5 reduces the pressure on the pusher 6 and the oil pressure in cavity B becomes lower than in cavity A. Check valve 3 opens and passes oil from cavity A connected to oil line of the engine, into cavity B. The pressure in cavity B increases, sleeve 9 and plunger 7, moving relative to each other, select the gap in the valve mechanism.

Pic. 5.8. Scheme of operation of the gap hydraulic compensator in the valve mechanism: a - operation of the hydraulic compensator at the time of valve opening; b - operation of the hydraulic compensator at the time of closing the valve; 1 - valve; 2 - check valve spring; 3 - check valve; 4 - cylinder head; 5 - camshaft cam; b - pusher; 7 - plunger; 8 - plunger spring; 9 - sleeve; 10 - check valve body; A, B - cavities of the hydraulic compensator; B - oil channel

The pressure of the oil supplied to the hydraulic lifters is regulated by a special valve installed in the cylinder head. Since, after the engine is stopped, oil drains from the channels leading from the oil pump into the oil sump, and the channels for supplying oil to the hydraulic compensators remain filled, after starting the engine, air locks may form in the cavities of the latter. To eliminate them, calibrated compensation holes are provided in the engine oil supply channels, which provide automatic purge of the hydraulic compensator cavities. In addition, compensation holes allow you to slightly reduce the pressure of the oil entering the hydraulic lifters at a high engine speed, when the pressure in the hydraulic lifter cavity can become so high that its pusher, leaning on the back of the camshaft cam, will slightly open the valve at a moment that does not correspond to the phase gas distribution.

Almost all malfunctions of hydraulic lifters are diagnosed by the characteristic noise emitted by the gas distribution mechanism in various engine operating modes.

Noise from valves can sometimes be eliminated by slightly turning the spring or valve around the longitudinal axis. To do this, do the following.

1. Rotate the crankshaft until the noisy valve opens slightly.

2. Turn the spring a little - the valve will turn at the same time.

3. Start the engine. If the noise persists, repeat steps 1 and 2.

4. If turning the spring and valve does not give the desired result, check the condition of the spring and measure the clearances between the valve stems and guide bushings (see «Dismantling, repair and assembly of the cylinder head»). Eliminate enlarged (compared to nominal) gaps.

If the valve and spring are in good condition, and the knock of the valves is still heard when the engine is running, the hydraulic compensator is faulty. Replace it like this.

1. Remove the engine head cover (see «Replacing the cylinder head cover gasket»).

2. Remove the camshafts from the cylinder head bearings (see «Removal, troubleshooting and installation of camshafts»).

3. Remove the hydraulic compensator from the socket of the cylinder head.

Warm tips: It is more convenient to remove the hydraulic lifter with a strong magnet, as shown in the photo, or a suction cup. Before installing, place the new hydraulic lifter in a container with engine oil, press the hydraulic lifter sleeve several times to remove air from it and fill it with oil.

4. Lubricate the socket in the block head with engine oil and install the hydraulic compensator in the socket.

5. The remaining hydraulic lifters are replaced in the same way.

6. Establish a camshaft and details of a drive of the gas-distributing mechanism in an order, the return to removal.