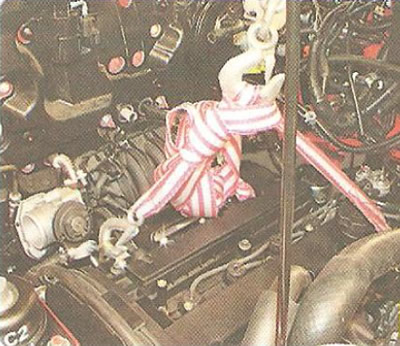

Helpful Hint: The engine is very heavy, so we recommend removing it with an assistant using special equipment (lift, hoist, etc.).

Warning: When removing and installing a power unit assembly with a large mass, use only fully serviceable lifting mechanisms designed for the appropriate load, and especially carefully control the correctness and reliability of connecting cables, traverses, etc. to the transport eyes of the engine.

You will need: keys «on 10», «at 12», «at 14», «at 17», pliers, flat blade screwdriver.

1. For convenience, remove the hood (see «Removal and installation of a cowl»).

2. Reduce the pressure in the supply system (see «Reducing the pressure in the power system»).

3. Remove the battery (see «Removing and installing the battery»).

4. Drain the liquid from the cooling system (see «Coolant replacement»).

5. If you remove the engine for repair, drain the oil from the oil sump (see «Changing engine oil and oil filter»).

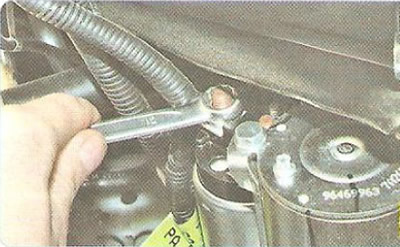

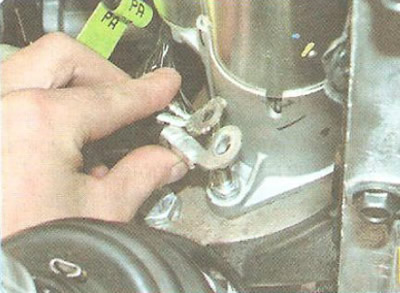

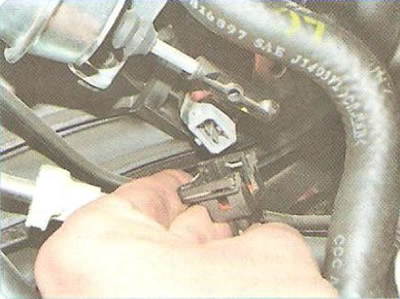

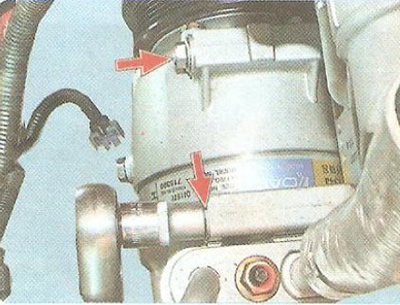

6. Turn away a fastening nut...

7.... and disconnect the power wire from the contact bolt of the starter traction relay.

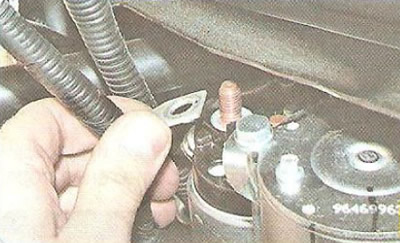

8. Turn away a nut of fastening of a control wire...

9.... and disconnect the wire from the contact bolt of the traction relay.

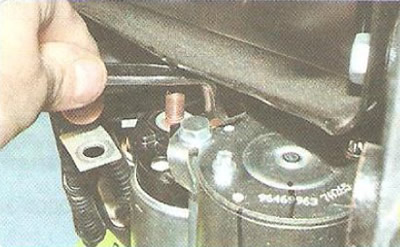

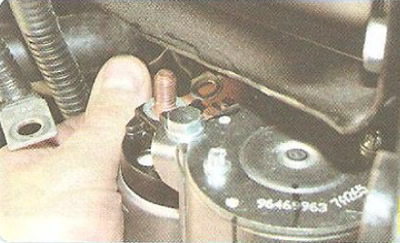

10. Loosen the nut...

11.... and remove the wire harnesses from the stud «masses».

12. Turn away a fastening nut and disconnect a wire from a contact bolt of the generator.

13. Disconnect the wiring harness block from the voltage regulator.

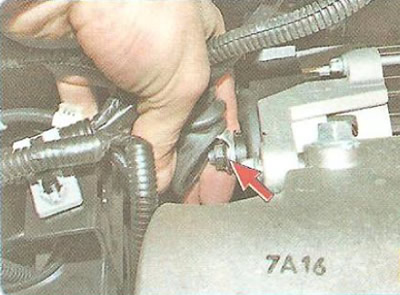

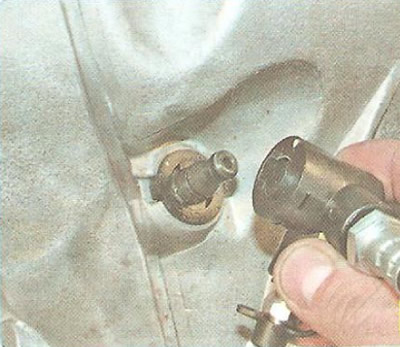

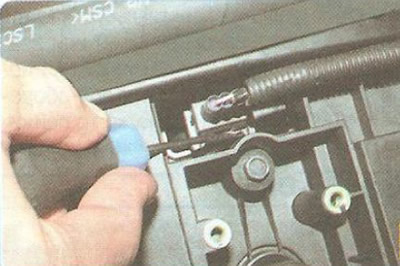

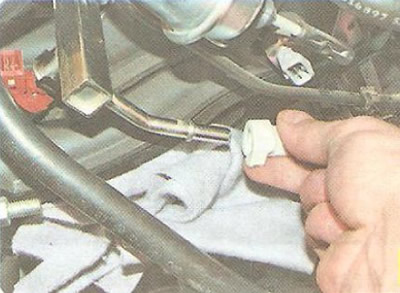

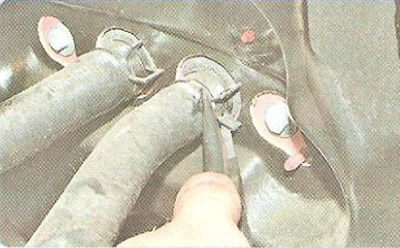

14. Pry off with a screwdriver...

15.... remove the spring retainer...

16.... and remove the drive hose adapter from the tip of the intermediate tube of the clutch release hydraulic drive.

17. Disconnect the wiring harness connector from the throttle assembly connector (see «Removal and installation of the throttle assembly»).

18. Loosen the clamp...

19.... and remove the air supply sleeve from the throat of the throttle assembly (see «Removal and installation of the air filter housing and intake silencer»).

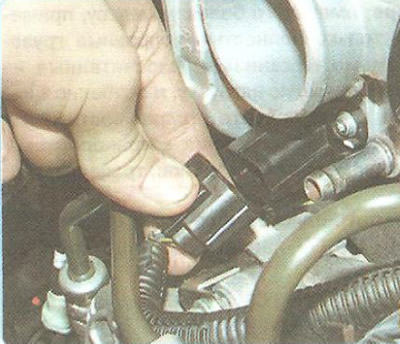

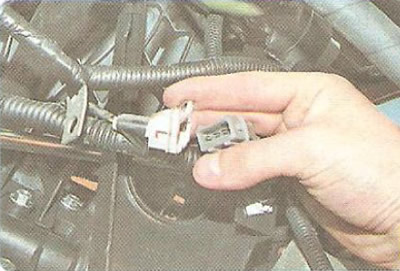

20. Wring out a clamp and disconnect a block of a plait of wires from throttle knot.

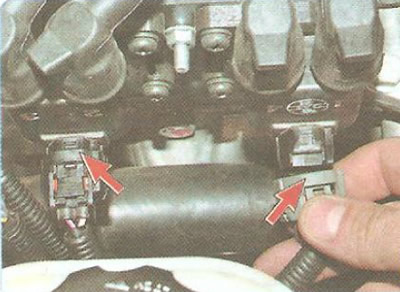

21. Press the latches and disconnect the wiring harness pads from the ignition coil...

22.... and from the EGR valve.

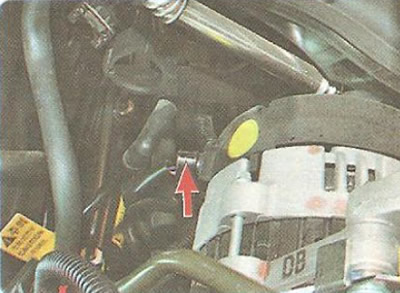

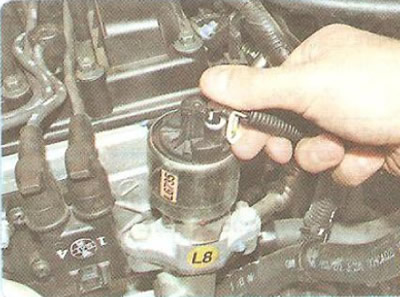

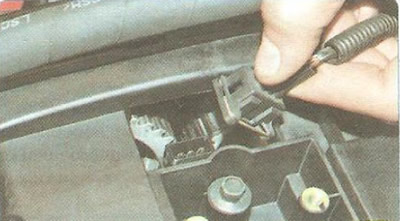

23. Pry off the spring retainer with a screwdriver...

24.... and disconnect the wiring harness block from the camshaft position sensor.

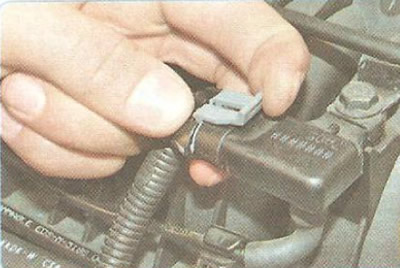

25. Press the latch...

26.... and disconnect the wiring harness block from the vacuum sensor in the intake pipe.

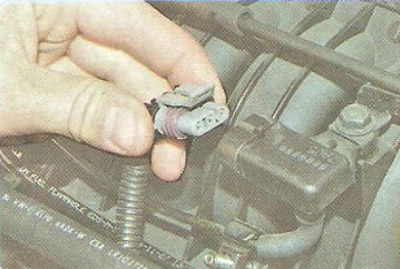

27. Disconnect the wiring harness pads from the injectors...

28.... and from the temperature sensor of the incoming air to the intake pipe.

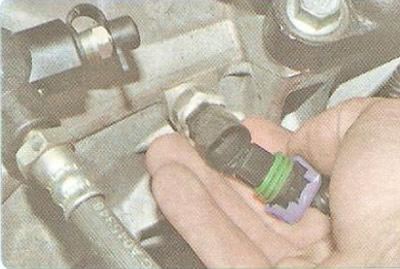

29. Squeeze the clamps and disconnect the fuel supply line from the fuel rail.

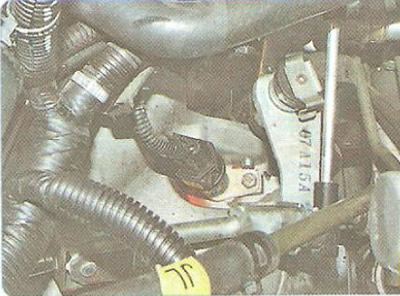

30. Disconnect the wiring harness block from the reversing light switch...

31.... from the speed sensor...

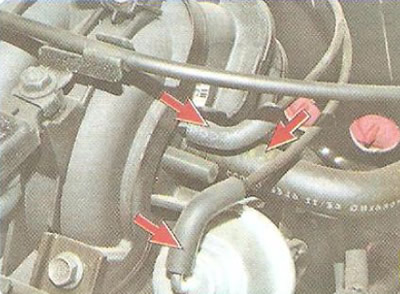

32.... and from the sensor of the signal lamp for an emergency drop in oil pressure.

33. Disconnect the knock sensor wiring harness connector.

34. Disconnect from the fittings the hoses of the system for changing the length of the channels of the intake pipe and the vacuum hose of the brake booster.

35. Remove downpipe (see «Downpipe replacement»).

36. Remove the catalytic converter (see «Removal and installation of catalytic converter»).

37. Remove the accessory drive belt (see «Accessory drive belt replacement»).

38. Unscrew the two nuts securing the power steering pump by turning the pulley until the holes in it match the nuts...

39.... unscrew the fastening nut of the power steering pump high pressure pipe bracket, remove the pump and take it aside.

40. Wring out clamps and disconnect block of a plait of wires from the conditioner compressor.

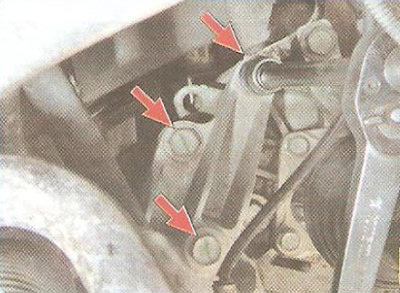

41. Turn out two bottom bolts of fastening...

42.... and two upper air conditioning compressor mounting bolts. Take the air conditioning compressor to the side without disconnecting the pipelines from it, and fix it on the body in any way possible (e.g. tie with wire).

43. Loosen the clamp of the radiator outlet hose of the cooling system, squeezing its bent ears, slide the clamp along the hose..

44.... and remove the outlet hose from the nozzle of the thermostat housing.

45. Loosen the clamp of the inlet hose of the radiator of the cooling system, squeezing its bent ears, slide the clamp along the hose...

46.... and remove the supply hose from the branch pipe of the water distribution pipe.

47. Loosen the clamp securing the heater radiator outlet hose by squeezing its bent ears, slide the clamp along the hose...

48.... and disconnect the outlet hose from the heater radiator pipe. Disconnect the supply hose in the same way.

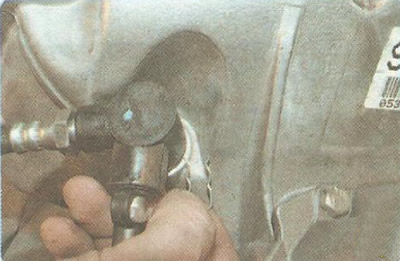

49. Loosen the bolt of the terminal clamp of the gearbox control drive...

50.... and disconnect the rod and the gear lever.

51. Remove the front wheel drives (see «Removal and installation of front wheel drives»).

Note: The front wheel drives do not need to be disconnected from the gearbox. In this case, fix the drives disconnected from the hubs on the power unit in any way possible (e.g. tie with wire).

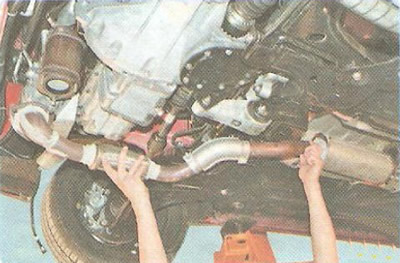

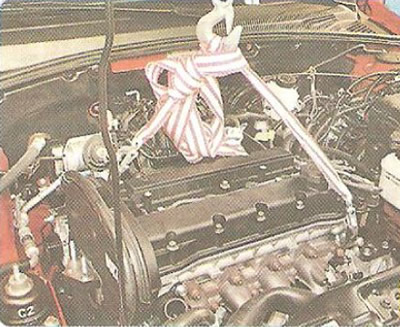

52. Attach the slings of the hoist to the front and rear transport eyes and tension the slings.

53. Support the engine securely.

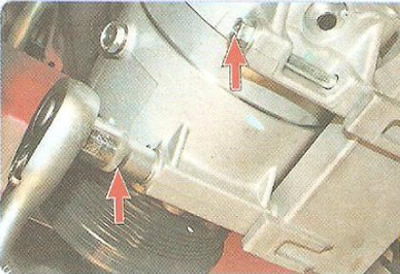

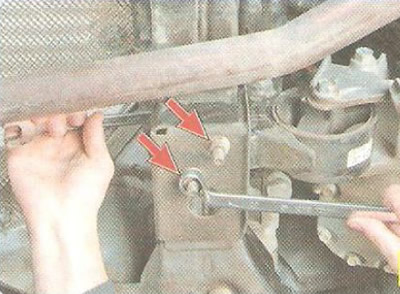

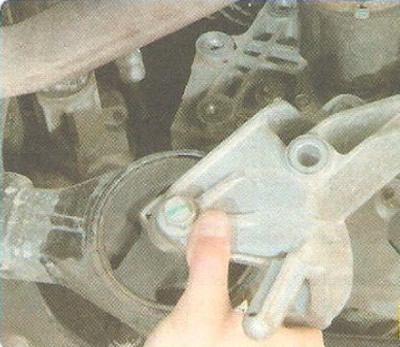

54. While holding the bolts of the pillow of the rear support of the power unit from turning, unscrew the nuts with the second wrench...

55.... unscrew the three bolts of the support bracket...

56.... and remove the pillow.

57. Turn out one bolt and turn away one nut of fastening of the power unit to the left support.

Note: Fuse box and battery tray removed for clarity.

58. Remove the right suspension bracket of the power unit (see «Replacing the suspension bearings of the power unit»).

59. Check again that all wires, hoses and attachments are disconnected from the power unit.

60. Remove the support from under the engine and lower the power unit down to the floor.

61. Hang the front of the car (raise the car on a lift) to a height sufficient to remove the power unit from under the vehicle, and place reliable supports under the body.

62. Remove the power unit from under the car.

63. Install the power unit, as well as all removed components and parts in the reverse order of removal, taking into account the following:

- before installing the power unit, clean the threaded holes for fastening its supports with a tap from rust;

- be sure to replace the inlet pipe and converter gaskets with new ones;

- when connecting wires and pipelines, carefully monitor their correct location in the engine compartment, avoiding contact with heating and moving elements of the power unit.

After installing the engine, do the following.

1. Fill engine oil (see «Changing engine oil and oil filter»).

2. Fill with coolant (see «Coolant replacement»).

3. Remove air from the hydraulic clutch release (see «Bleeding the hydraulic clutch release»).

4. Start the engine and check for fuel, oil and coolant leaks. Check oil pressure. Listen to the engine: it should run smoothly, without extraneous noise and knocks.