- the pressure in the engine lubrication system has dropped. The cause of this malfunction is often increased wear on the camshaft journals and the camshaft bearing housings in the cylinder head. When the sockets are worn out, the head of the block is replaced as an assembly, since the sockets are made directly in its body;

- knocking of valves with serviceable hydraulic gap compensators in the valve drive mechanism. Caused by increased wear of the camshaft cams due to the use of low-quality engine oil or damage to the oil filter.

You will need: all the tools needed to remove the timing belt (see «Replacing the timing belt and its tension roller»), as well as a screwdriver, micrometer.

1. Disconnect the wire from the terminal «minus» battery.

2. Remove the cylinder head cover (see «Replacing the cylinder head cover gasket»).

3. Remove the air filter and disconnect the air supply pipe from the throttle assembly (see «Removing and installing the air filter housing and intake noise damper»).

4. Remove the camshaft drive belt (see «Replacing the timing belt and its tension roller»).

5. Remove the toothed pulleys from the intake and exhaust camshafts (see «Replacing camshaft seals»).

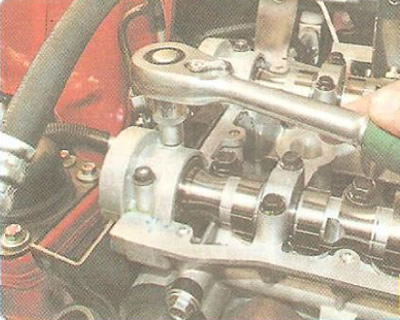

6. Turn out on two bolts of fastening of covers of forward bearings of camshafts...

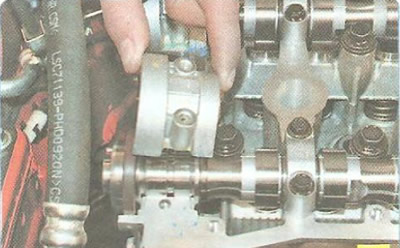

7....remove covers...

8.... and remove the camshaft seals.

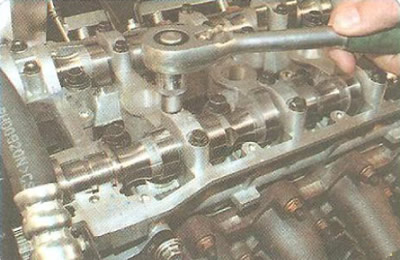

9. Turn out on two bolts of fastening of other covers of bearings of camshafts, remove covers...

Warning: Mark the covers in any way to reinstall them in their original positions.

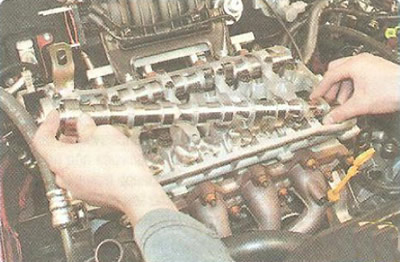

10.... and remove the camshafts.

Warning: Mark the camshafts in any way in order to install them in their original places during assembly.

11. Carefully inspect the surfaces of the camshaft bearing caps and bearing journals on the cylinder head. If the bearing surfaces are excessively damaged, replace the cylinder head, as the bearing caps are machined complete with the cylinder head and cannot be depersonalized.

12. Carefully inspect the camshafts. The threads in the holes for fastening the toothed pulley must not be damaged or worn. The surfaces of the bearing journals and cams must be well polished and without damage. On the working surfaces of the necks, scoring, nicks, scratches, aluminum enveloping from the bearing seats in the block head are not allowed. If there are signs of seizing, overheating, deep scratches or wear in the form of a cut on the working surfaces of the cams, replace the shaft.

Warning: Grinding the camshaft cams to eliminate stepped wear is prohibited, since changing the size of the cam profile will disrupt the valve timing.

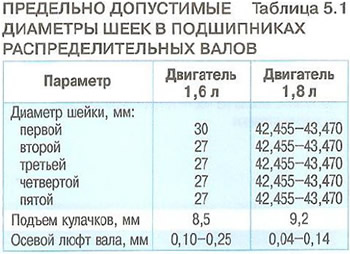

13. Measure the diameters of the bearing journals of the camshafts and their bearings, calculate the clearances in the shaft bearings, determined by the difference between the diameters of the bearings in the cylinder head and the diameters of the necks (tab. 5.1). If the wear exceeds the allowable, replace the camshaft, since regrinding of the necks to the repair size is not provided.

14. Establish camshafts and all removed details in an order, the return to removal.

15. Adjust the tension of the timing belt (see «Checking the timing belt»).