You will need; tools needed to remove the gearbox and clutch, as well as a wrench «at 19», large screwdriver.

1. Remove the gearbox (see «Removal and installation of a manual transmission») and clutch (see «Removal and installation of clutch»).

2. Mark in any way the relative position of the flywheel and crankshaft.

Note: The flywheel can only be installed on the crankshaft in one position, since one of the holes in the flywheel and the crankshaft is located asymmetrically (has an angular displacement), however, to facilitate the installation of the flywheel, we recommend that you mark the relative position of the parts.

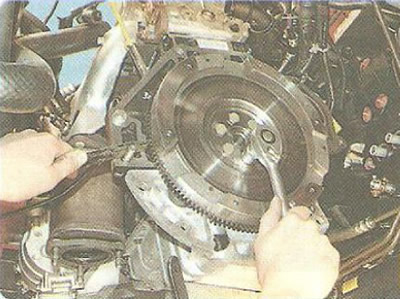

3. Turn out five bolts of fastening of a flywheel. At the same time, use a screwdriver or a mounting spatula to keep the flywheel from turning by first screwing in one of the gearbox mounting bolts.

4. Turn out the sixth bolt and remove a flywheel.

5. Check the condition of the flywheel rim teeth and replace the flywheel if damaged.

6. Replace or repair the flywheel if on the contact surfaces of the clutch driven disc...

7.... or crankshaft flange marks and burrs are found.

8. You can check and repair the flywheel in a workshop with special equipment. The flywheel runout, measured on the ring gear, should not exceed 0.5 mm. To remove deep scratches and scuffs, the contact surface of the driven disk can be ground, while the layer of metal being removed should not exceed 0.3 mm.

9. Establish a flywheel and all removed knots in sequence, return to removal. Lubricate the threads of the flywheel mounting bolts with an anaerobic thread locker, having previously degreased the bolts and threaded holes for them, Tighten the bolts evenly crosswise with a torque of 35 Nm (3.5 kgf·m) and further tighten by an angle of 30°, and then another 15°.