Helpful advice: If possible, work on a special turntable that provides access to the engine from all sides, since it is very difficult to fix the engine from moving when unscrewing fasteners tightened with a large torque.

1. Remove the engine from the car (see «Removal and installation of the engine»).

2. Remove the starter (see «Removal and installation of a starter»).

3. Remove generator (see «Removal and installation of the generator»).

4. Disconnect the gearbox from the engine by unscrewing the bolts of its fastening to the engine (see «Removal and installation of a manual transmission»).

5. Remove the clutch from the flywheel (see «Removal and installation of clutch»).

6. Remove the flywheel (see «Removal, troubleshooting and installation of the flywheel»).

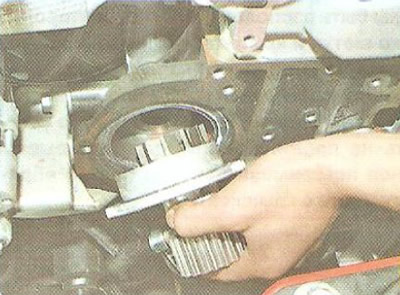

7. Remove the timing belt (see «Replacing the timing belt and its tension roller») and rear drive cover (see «Removal and installation of the oil pump»).

8. Remove the cylinder head (ohm. «Replacing the cylinder head gasket»).

9. Remove the oil pan (see «Replacing the oil sump seal»),

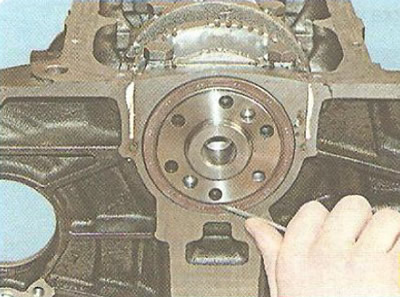

10. Prying with a screwdriver, remove the crankshaft rear oil seal from the cylinder block socket.

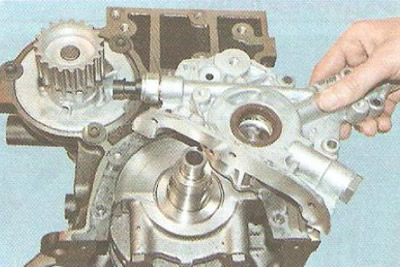

11. Remove the oil receiver, oil pump and the gasket installed under it (see «Removal and installation of the oil pump»).

12.... as well as a water pump (see «Water pump replacement»).

13. Remove the oil filter (see «Changing engine oil and oil filter»).

Helpful advice: When disassembling the crank mechanism and the piston group, mark the pistons, connecting rods, main and connecting rod bearing shells in order to install them in their original places during assembly, if they are operational.

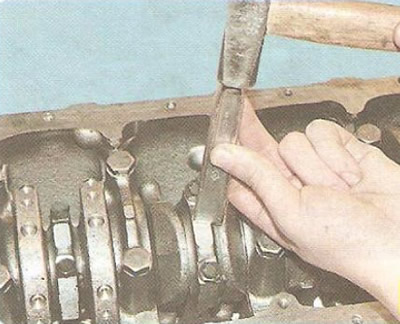

14. Turn out two bolts of fastening of a cover of a rod of any cylinder, shift a cover of a rod from a seat easy blows of a hammer through a wooden spacer...

15.... and remove the cover with the insert.

Warning: Conventional markings are applied to the cap and connecting rod (triangle icon and number). When assembling the engine, the number and icon must be located on the same side. However, the connecting rod and cap are not marked with cylinder numbers. Be sure to label them in any way possible (for example, punching), in order to install in their original places during assembly, since the connecting rod caps are not interchangeable (connecting rod machined together with cover).

16. Press with a wooden block (hammer handle) on the rod...

17.... and remove the piston with the connecting rod from the cylinder towards the upper plane of the cylinder block.

18. Similarly, remove the pistons and connecting rods of the remaining cylinders, turning the crankshaft to access the connecting rod cap bolts.

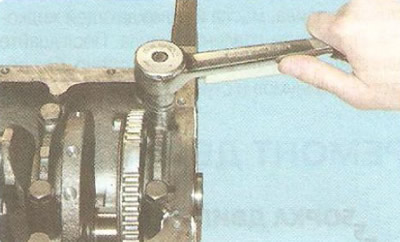

Helpful Hint: Turn the crankshaft with a wrench by the flat on its front end.

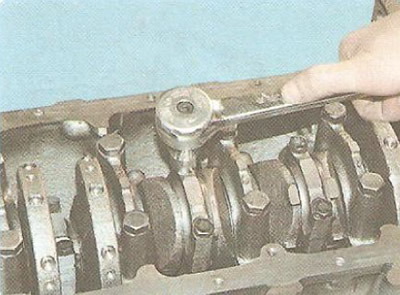

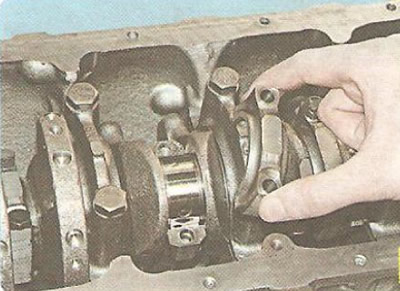

19. Turn out two bolts of fastening of any cover of the radical bearing. Separate the cover from the seat with light blows of the hammer through the wooden spacer...

20.... and remove the cover with the bottom insert.

Warning: Main bearing caps are designed for one specific cylinder block only (covers are processed together with the block). The covers are not interchangeable with each other. The covers are numbered according to the order in which they were installed, counting from the front of the engine (There is no number on the 5th main bearing cap). Letters cast on lids «VC» when installed, point towards the left side of the engine.

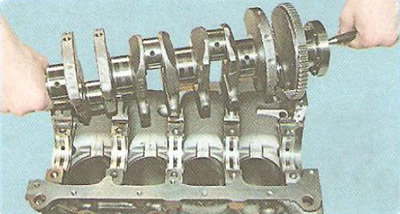

21. Turn out bolts, remove other covers of radical bearings and take a cranked shaft.

22. Remove the liners from all connecting rods...

23....and off their lids...

24.... from the main bearing caps...

25.... and from all beds in the cylinder block.

Note: The bushing of the cover of the third main bearing of increased thickness has flanges on the side ends, which play the role of thrust semi-rings that limit the axial movement of the crankshaft.

Similar collars are made on the upper shell of the third main bearing.

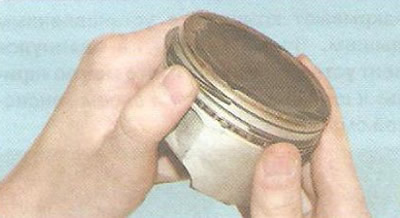

26. Unclench the top compression ring...

27....and take it off.

28. Similarly, remove the lower compression ring.

29. Unclench and remove the top ring...

30.... expander...

31.... and the lower ring of the composite oil scraper ring.

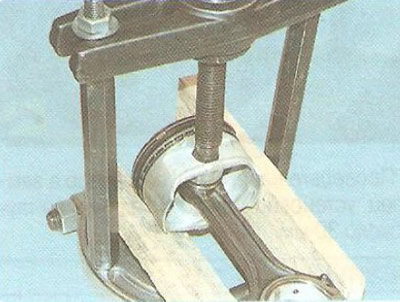

32. Press out a finger from piston bosses and an upper head of a rod.

Notes: Do not heat the connecting rod before pressing out the pin. In order not to damage the piston, use wooden spacers when pressing out the pin, as shown in the photo.

Helpful Hint: Label the details. If they are not damaged and slightly worn, they can be used by installing them in their original places.