Currently, hundreds of tire models from dozens of manufacturers are on sale. This section is designed to help car owners understand the main features of tire design and make the right choice when buying.

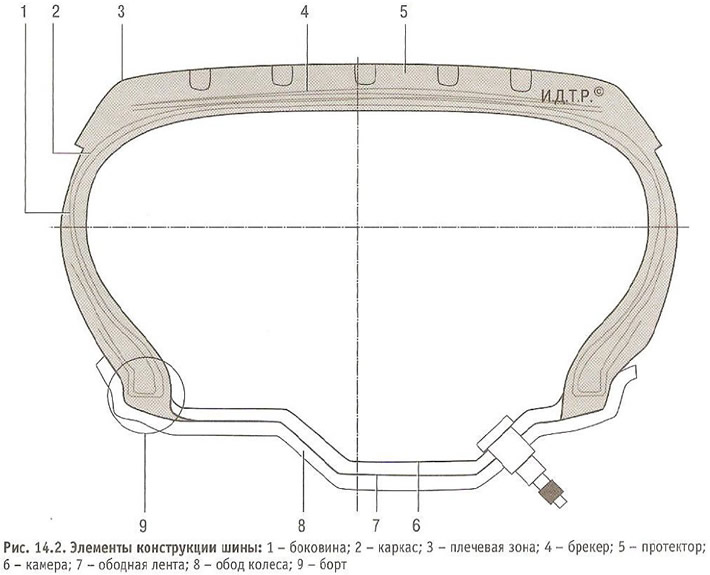

The design of the pneumatic tire is shown in fig. 14.2.

Frame 2 (see fig. 14.2) - the most important power part of the tire, providing its strength, perceiving internal air pressure and transmitting loads from external forces acting on the wheel from the side of the road.

The carcass consists of one or more layers of rubberized cord superimposed on each other. In modern tires with a radial carcass design (with an inscription «RADIAL» on the sidewall) the cord is stretched from one side to another without overlapping threads. This arrangement of the cord layers reduces the tension in the threads, which makes it possible to reduce the number of layers, gives the carcass elasticity, reduces heat generation and rolling resistance.

Breaker 4 - part of the tire, consisting of layers of cord and located between the carcass and the tread of the tire. The breaker serves to improve the connections of the carcass with the tread, prevents its delamination under the action of external and centrifugal forces, absorbs shock loads and increases the resistance of the carcass to mechanical damage.

Depending on the material of the cord, tires are divided into tires with a textile breaker, tires with a metal breaker and solid steel cord tires (when using steel cord both in the breaker and in the frame). The sidewalls of tires with a metal breaker are sometimes marked «STEEL BELTED» (belted with steel).

Protector 5 - the outer part of the tire, which is a massive layer of rubber. A relief pattern in the form of protrusions and grooves is made on the outer surface of the tread (lamellas), the so-called treadmill. The pattern of the relief part determines the suitability of the tire to work in various road conditions. The wear resistance of the tire and the grip of the wheel with the road, as well as the level of noise and vibrations, depend on the quality of the tread.

Shoulder area 3 - the part of the tread located between the tread and the sidewall of the tire. It increases the lateral stiffness of the tire, absorbs part of the side loads transmitted by the treadmill, and improves the connection between the tread and the carcass.

Sidewall 1 - part of the tire located between the shoulder area and the bead. The sidewall is a relatively thin layer of elastic rubber, which is a continuation of the tread on the side walls of the carcass and protects it from moisture and mechanical damage. Tire designations and markings are applied to the sidewalls.

Board 9 - the rigid part of the tire, which serves to fasten and seal it (if the tire is tubeless) on the wheel rim.

The basis of the bead is an inextensible ring woven from rubberized steel wire. The bead consists of a layer of cord wrapped around a wire ring and a round or profiled rubber filler cord.

The steel ring gives the board the necessary rigidity and strength, and the filler cord gives solidity and an elastic transition from the rigid ring to the sidewall rubber.

On the outer side of the bead there is an onboard tape made of rubberized fabric or cord, which protects the bead from abrasion against the rim and damage during installation and dismantling.

The vast majority of modern car tires are tubeless. In them, the tightness of the internal cavity is achieved by the special structure of the tire itself and the wheel rim.

In tube tires, the connection between the beads and the rim is leaky; rubber is used in the construction of such tires camera 6 and rim tape 7.

In service, tubeless tires are considered more reliable than tubed tires because when a tire is punctured, air only exits the tire through the puncture hole, while in tubeless tires, air flows out of the tire cavity around the entire circumference of the mounting hole. For this reason, a tubeless tire leaves more time to maneuver before the moment when riding on a damaged tire becomes dangerous. In addition, tubeless tires are lighter than their tubeless counterparts.