Conventionally, three types of jerks can be distinguished:

- at the moment of the beginning of the movement;

- during acceleration;

- with steady motion, i.e. at a constant position of the gas pedal.

To determine the causes of jerks when driving a car with an injection engine, special diagnostic equipment is required, so we recommend contacting a service that specializes in repairing fuel injection systems. However, as practice shows, in most cases, jerks are caused by insufficient fuel pressure in the fuel rail or a malfunction of the throttle position sensor.

With some skills, the cause of jerks can be identified independently.

Jerk at the moment of the beginning of the movement

At the moment of the beginning of the movement, there is more often an extreme case of a jerk - a failure. The most unpleasant sensations are associated precisely with the delay in the response of the engine to pressing the gas pedal. Sometimes the engine even stalls.

A jerk occurs at the moment the throttle valve starts to open, when, according to the signal from the throttle position sensor, the electronic control unit (ECU) determines the moment of transition from idle to load mode and should increase the amount of fuel supplied through the injectors. With insufficient pressure in the fuel rail, even with an increase in the duration of injection, there is not enough fuel for a smooth start. The procedure for checking fuel pressure is described in subsection «Checking the pressure in the engine power system».

Jerks during acceleration

The cause of jerks during acceleration can be, as in the previous case (see «Jerk at the moment of the beginning of the movement»), insufficient fuel pressure in the fuel rail. The electronic engine control unit, having received a signal from the throttle position sensor about the intensive opening of the damper at a large angle, seeks to maximize the fuel supply, but due to the reduced fuel pressure it is not able to do this. The reasons for this phenomenon and the method of verification, see subsection «Jerk at the moment of the beginning of the movement».

A specific cause of jerks during acceleration of a Chevrolet Cruze may be a failure of the pressure sensor in the intake pipe. In addition to the reasons indicated, jerks during acceleration of a car with an automatic transmission can be caused by an insufficient amount of working fluid in the box (see «Checking the level, topping up and changing the oil in a manual transmission»; «Checking the level and topping up the working fluid in the automatic transmission», and a malfunction of the box itself.

Note: An automatic transmission vehicle may experience jerky acceleration at the start of the first trip after disconnecting and reconnecting the battery. This is not a malfunction, because after several accelerations, the electronic unit will calibrate the gearbox control and the gear shift will become smooth.

Jerks in steady motion

Such jerks are most often caused by a malfunction of the ignition system. Diagnosis and repair needed (see sect. 10 «electrical equipment»). On the way, you can try to do the following yourself:

- carefully inspect the underhood space. Switch off the ignition and check the reliability of fastening and landing of all wires and connectors at the ignition coil and high-voltage wires. Start the engine and listen to its work: crackling during the breakdown of high voltage current «to ground» weak but distinct. In complete darkness, a spark is clearly visible during breakdown;

- replace spark plugs regardless of their condition and mileage. Pay attention to the condition of the candles: if it is not up to standard, it may be necessary to repair the engine or its systems.

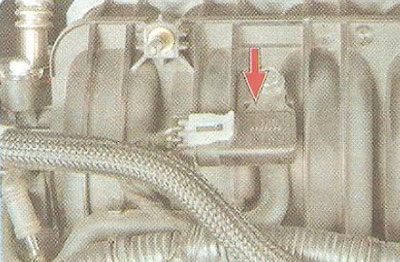

A specific cause of jerks during the steady movement of a car with an injection engine may be a failure of the throttle position sensor (shown in the photo by an arrow with the air supply sleeve removed for clarity), combined in one node with the idle speed controller, Additional symptoms confirming the malfunction of this sensor are:

- uneven engine idling;

- reduction in engine power.

The sensor is non-separable and therefore non-repairable. If a sensor failure is detected (see «Check and replacement of gauges of a control system of the engine»), replace the sensor or throttle assembly.