You will need a Phillips screwdriver.

1. Pre-check and, if necessary, bring the air pressure in the tires to normal.

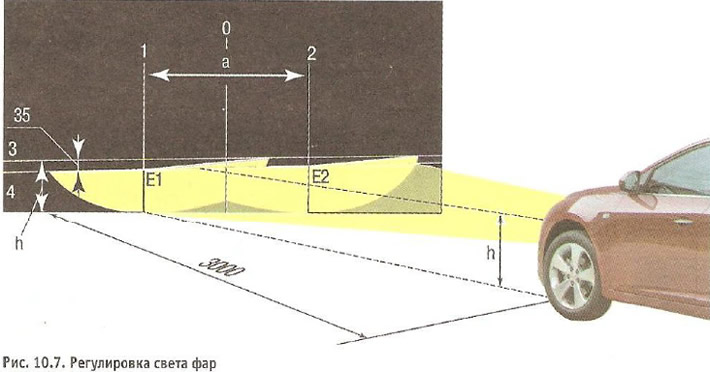

2. Install the car perpendicular to a smooth wall (e.g. in the garage) at a distance of 3 m. Place a weight of 75 kg on the driver's seat. Mark the screen on the wall as shown in fig. 10.7. The longitudinal plane of symmetry of the car must pass along line 0 on the screen. Vertical lines 1 and 2 are located at an equal distance from line 0. The distance a between lines 1 and 2 must be equal to the distance between the centers of the dipped-beam lamps. Rock the car from the side so that the suspension springs self-adjust.

3. Measure the height of the headlight centers on your vehicle from the ground. This will be the distance h on the screen.

4. Set the headlight electrocorrector control on the instrument panel to the position corresponding to the load of the car with one driver.

5. Turn on low beam.

6. It is recommended to adjust the direction of the light spot for each headlight individually. Cover the second headlight with an opaque material during adjustment.

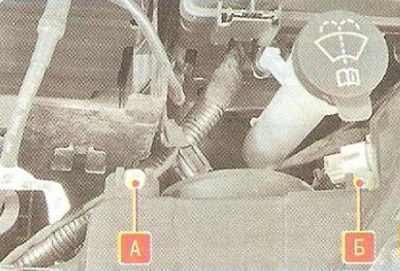

Note: This is how the headlight adjustment screws are located horizontally A and vertically B.

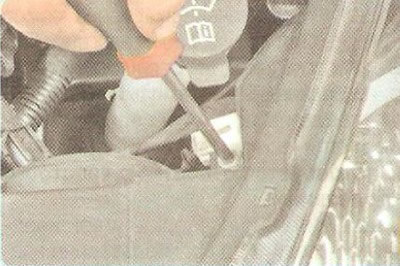

7. Open the hood and turn the adjusting screws to adjust (if the location of the light spots does not match the drawing) position on the screen of the light spot for each headlight horizontally...

8....and vertically.

9. The headlights are considered adjusted when the upper borders of the left parts of the light spots coincide with line 4, and vertical lines 1 and 2 pass through points E1 and E2 (see fig. 10.7) intersections of horizontal and inclined sections of light spots.