If there are scuffs, deep scratches and other defects on the working surface of the disc that increase pad wear and reduce braking efficiency, as well as in case of increased lateral runout of the disc, causing vibration during braking, replace the disc. In specialized workshops, such a disc can be machined and polished on both sides to the same depth, but after processing, the thickness of the disc must not be less than the minimum allowable.

The minimum permissible thickness of the brake disc of the brake mechanism of the front wheel is 24 mm. If the thickness of one of the discs is less than the specified value, replace both discs. When replacing brake discs, be sure to replace the brake pads with a new set.

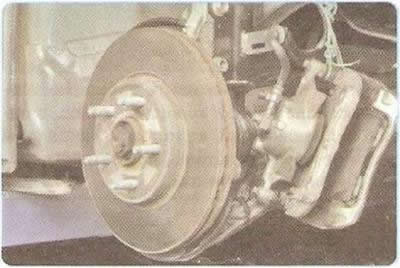

1. Remove the wheel from the side of the disc being replaced.

2. Turn out bolts of fastening directing blocks to a rotary fist.

3. Remove the caliper assembly without disconnecting the brake hose and secure with wire without twisting or pulling the hose (see «Replacing the front wheel brake caliper assembly»).

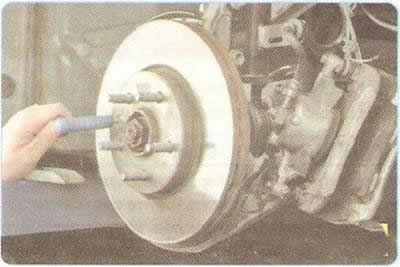

4. Turn out the screw of fastening of a disk to a nave...

Hold the hub from turning with a mounting spatula by resting it on the wheel nuts screwed onto the studs.

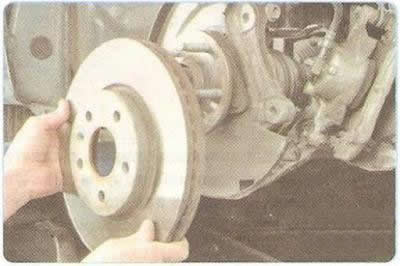

5....and remove the disc.

6. Install the parts in the reverse order of removal.

Note: Before installing the disc, carefully clean the mating surfaces of the hub and disc from rust and scale, as even the smallest particle sandwiched between the mating surfaces will cause the disc to run out and vibrate when braking,

7. Press the brake pedal all the way down several times. This is necessary in order to select the gaps in the brake mechanism that appeared after the pistons were pressed into the cylinders,

8. Install the wheel.

9. Similarly remove a brake disk of other wheel.