1. Remove the compressor (see «Removal and installation of the compressor of the conditioner»).

2. Remove drive pulley (see «Drive pulley bearing replacement»).

3. Mark position (e.g. marker) the electrical connector of the magnet relative to the compressor housing.

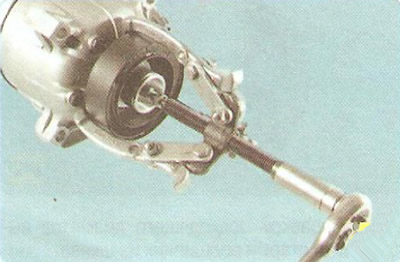

4. Install the three-arm puller...

5.... and press the magnet from the seat belt of the compressor front cover.

6. Using an ohmmeter, check the resistance of the coil winding of the electromagnet and the absence of a short to the housing. The resistance of a good coil should be 3.6-3.8 ohms.

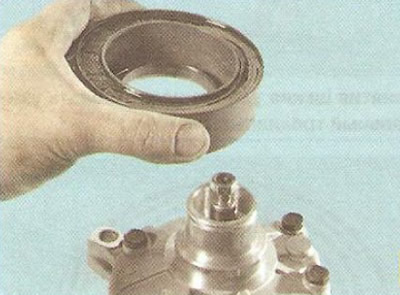

7. Reassemble in reverse order. Install the coil, electromagnet on the compressor, aligning the marks made during installation.

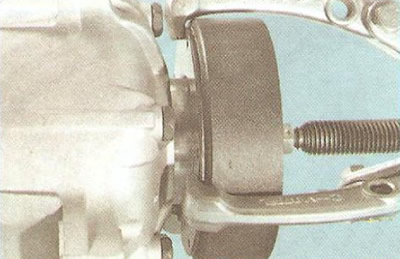

8. Press on the magnet. When pressing on, apply force only to the inner race of the magnet housing. Avoid twists.

Note: To press the coil, use a special mandrel or a piece of pipe of a suitable diameter.

9. Press on the pulley and pressure plate (see «Drive pulley bearing replacement»).

Warning: After pressing the pulley, check for ease of rotation. Rotation should be uniform, silent, without jamming. There should be no contact with the body of the electromagnet. If during the check it is found that the pulley touches the magnet, eliminate it.

10. Install the compressor in the reverse order of removal.

11. Charge the air conditioning system with refrigerant at a specialized auto air conditioning service center.