1. Remove the refrigerant from the air conditioning system (see «Removing refrigerant from the air conditioning system»).

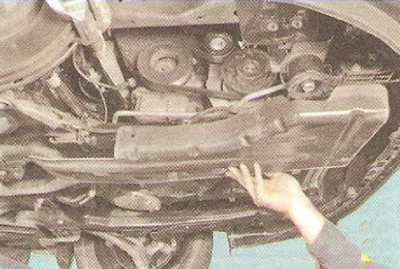

2. Install the car on an inspection ditch.

3. Disconnect the wire from the terminal «minus» battery.

4. Remove the lower front bumper trim (see «Removal and installation of a forward bumper»).

5. Remove the right engine mudguard (see «Removal and installation of engine mudguards»).

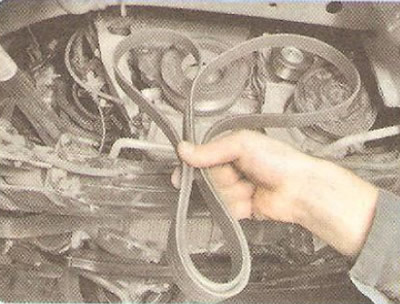

6. Remove the accessory drive belt (see «Accessory drive belt replacement»).

7. Check the condition of the drive belt.

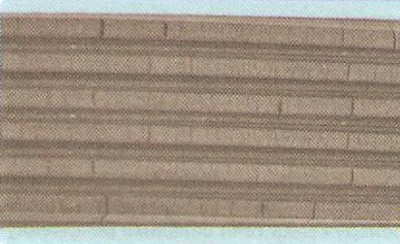

Note: Replace the belt if, upon inspection, you find:

- signs of wear on the toothed surface, cracks, undercuts, folds or delamination of the fabric from the rubber;

- cracks, folds, depressions or bulges on the outer surface of the belt;

- loosening or delamination on the end surfaces of the belt;

- traces of oil on the surface of the belt.

Warning: A belt with traces of engine oil on any surface must be changed without fail, as the oil quickly destroys the rubber. Cause of oil on the belt (usually due to leakage of the engine shaft seals) must be eliminated immediately.

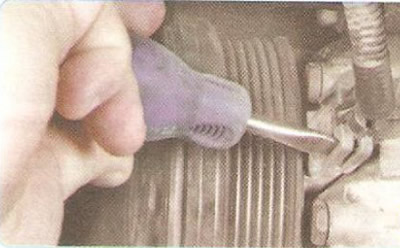

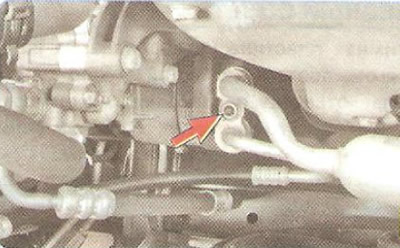

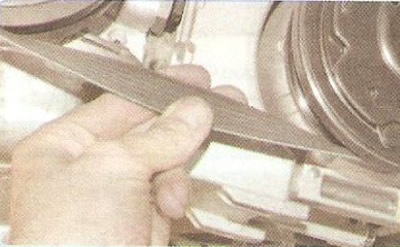

8. Press the latches...

9.... and disconnect the wiring harness block from the electromagnetic clutch for turning on the compressor.

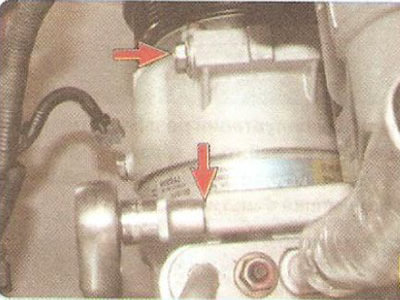

10. Turn away a nut of fastening of a pressure plate of the block of hoses to the compressor.

11. Disconnect the low and high pressure pipe flanges from the compressor.

Warning: Immediately after disconnecting, plug the compressor and A/C piping to prevent moisture and dirt from entering the A/C system.

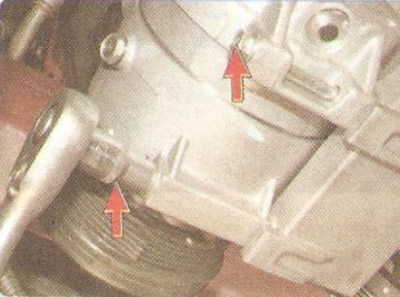

12. Remove the top two...

13.... and two lower bolts securing the compressor to the bracket

14. Remove the bolts from the mounting holes and remove the A/C compressor.

15. Install the compressor and all removed parts in the reverse order of removal.

Warnings: Open the process flange plugs of a new compressor only immediately before connecting the pipelines.

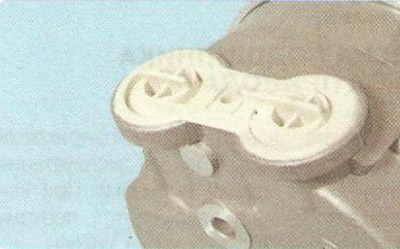

The flange of the pipeline unit is sealed with two rubber-metal sealing rings. When the rings are crimped, the metal rim is deformed, therefore, such rings are not suitable for reuse.

When installing new pipe block flange O-rings, be sure to lubricate them with A/C compressor oil.

16. Make sure that when installing the belt, the wedge tracks match the grooves of the pulleys.

17. Tighten the nut securing the pressure plate of the hose block to the compressor to 33 Nm.

18. Charge the A/C system with refrigerant at an authorized vehicle air conditioner service center.

Helpful Hint: When buying a new compressor, check with the seller the amount and type of oil filled in the new compressor. This information may be useful to mechanics who later charge the system with refrigerant.