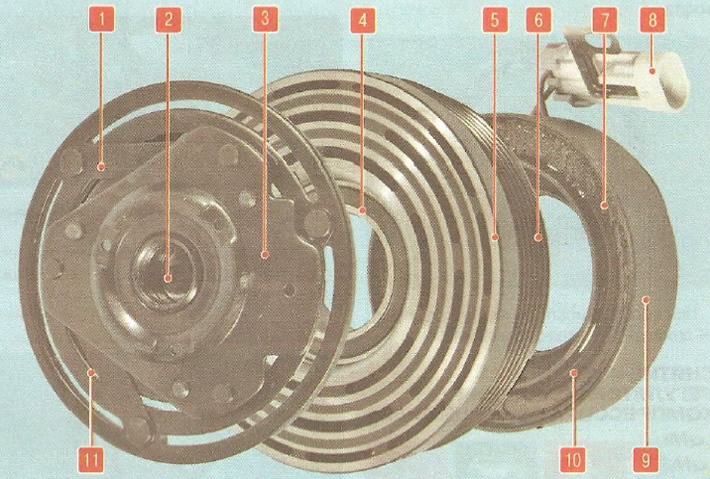

Pic. 12.5. Compressor drive electromagnetic clutch: 1 - elastic steel leash; 2 - threaded hole of the disc hub; 3 - clutch driven disc; 4 - inner race of the bearing; 5 - bearing; 6 - working surface of the pulley; 7 - pulley streams; 8 - electrical connector block; 9 - body of the electromagnet; 10 - electromagnet winding; 11 - clutch pressure plate

When operating a car, the failure of the compressor clutch is a very common malfunction. As a rule, bearing 5 begins to collapse first (pic. 12.5) pulley. The cause may be incorrect tension of the drive belt, water ingress when driving through a deep puddle, slippage of the pressure plate and, consequently, overheating of the bearing, etc. As the bearing deteriorates, play begins to appear. When the backlash reaches a critical value, the inner surface of the pulley during rotation begins to rub against the surface of the body 9 of the electromagnet coil.

As a result of friction, the parts heat up and the insulation of the winding 10 of the coil begins to burn out. An electrical short occurs - the electromagnet fails. In the most advanced cases, the bearing jams and the inner race of the bearing 5 turns on the landing neck of the compressor cover. After that, you have to carry out an expensive replacement of the compressor in a specialized service,

In order not to expose yourself to unnecessary expenses, when inspecting the car, pay attention to uncharacteristic noises during the operation of the air conditioning compressor. If you suspect a problem with the pulley bearing, remove the drive belt (see «Accessory drive belt replacement») and turn the pulley by hand. It should rotate on the bearing evenly, silently, without jamming. There must be no axial and radial play.

If necessary, replace the bearing without waiting for its complete destruction.