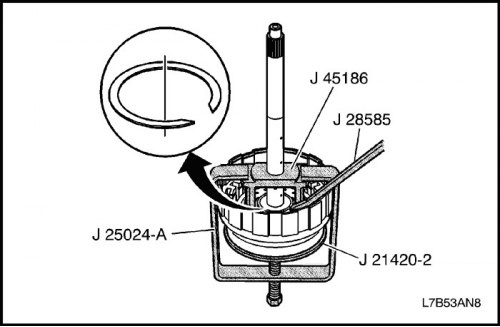

Necessary equipment

- J-28585 Retaining Ring Remover

- J-45186 Forward and Direct Clutch Spring Remover

- J-25024-A Clutch Spring / Booster Piston Puller

- J-23327 Clutch Spring Remover

1. Install the forward clutch piston (C1).

- Lubricate new o-rings with automatic transmission fluid and install them on the C1 piston.

- Lubricate the inner surface of the drum with automatic transmission fluid.

- Press piston C1 into drum. Care must be taken not to damage the O-rings.

2. Install direct clutch (C2).

- Lubricate new o-rings with automatic transmission fluid and install them on the piston.

- Lubricate the inner surface of the C1 piston with automatic transmission fluid.

- Push piston into piston C1.

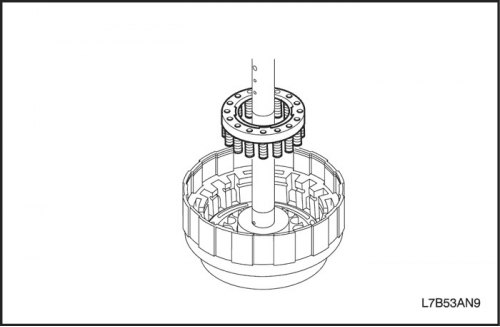

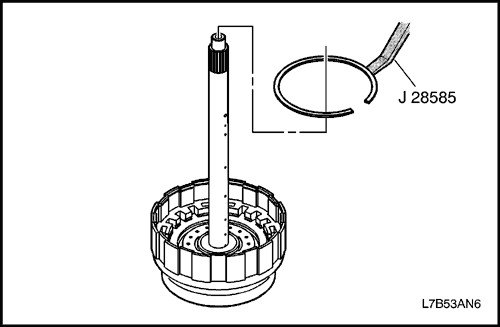

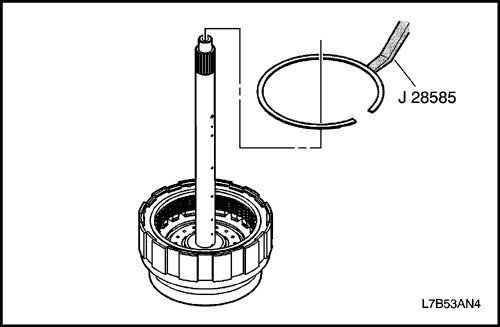

3. Install return spring assembly.

- Install the return spring assembly to the direct clutch piston (C2).

Important: It is forbidden to combine the cut of the retaining ring with the fixing protrusion of the spring.

- Place J-25024-A in a vise with the pressure bolt at the bottom and back.

- Install J-45186 onto the direct/forward clutch housing shaft and input shaft assembly.

- Place J-21420-2 from J-23327 on top of J-24024-A push bolt.

- Compress the clutch spring with the pressure bolt so that the retaining ring can be installed.

- Using J-28585 or circlip pliers, install the circlip.

- Remove tools.

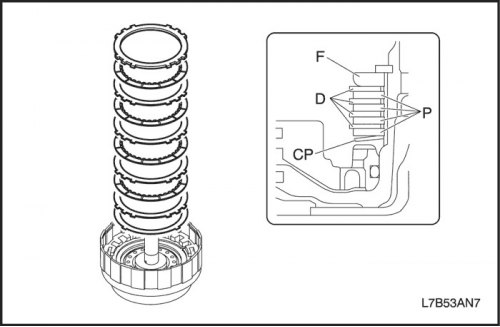

4. Install direct clutch flange, disc, plate and spring disc (C2).

- Install elastic disk.

Important: Make sure the direction of the elastic disk is correct.

- Install flange, discs and plates as shown.

Important: Make sure that the number and order of installation of the flange and discs and plates are correct.

- Order: F - D - P - D - P - D - P - D - P - UD

|

Clutch and brake

|

Flange (F)

|

plate (P)

|

Disk (D)

|

elastic disk (UD)

|

|

Direct clutch (C2)

|

1

|

4

|

4

|

1

|

- Using J-28585, install the circlip into the groove. Make sure the snap ring cut does not line up with any of the cutouts.

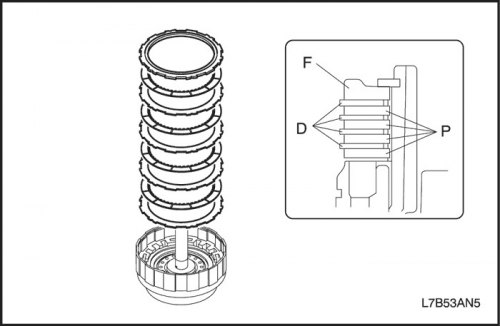

5. Install direct clutch flange, disc and plate (C1).

- Install flange, discs and plates as shown.

Important: Make sure that the number and order of installation of the flange and discs and plates are correct.

- Order: F - D - P - D - P - D - P - D - P

|

Clutch and brake

|

Flange (F)

|

plate (P)

|

Disk (D)

|

|

Forward clutch (C1)

|

1

|

4

|

4

|

- Using J-28585, install the circlip into the groove. Make sure the snap ring cut does not line up with any of the cutouts.

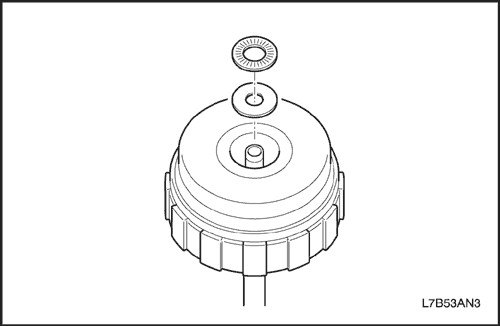

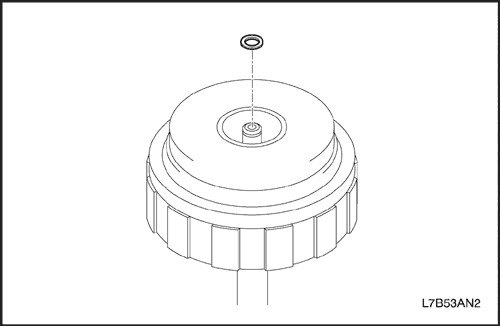

6. Install o-ring, thrust bearing and race.

- Install thrust bearing and race.

- Lubricate a new sealing ring with automatic transmission fluid, install it in the groove of the input shaft assembly.

Attention! Protective goggles should be worn when working with compressed air to prevent injury to the eyes.

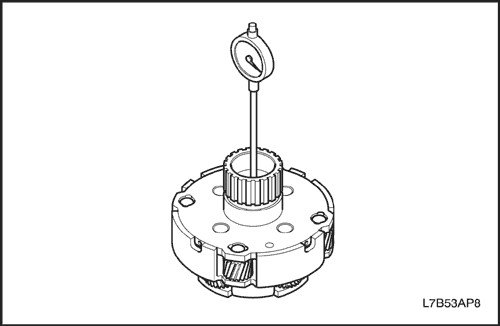

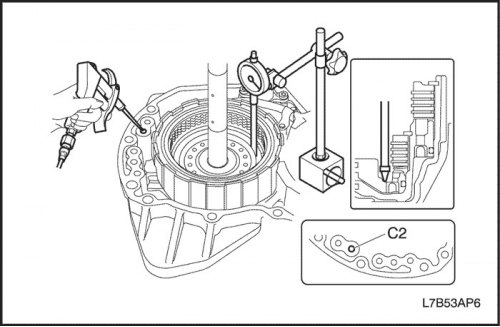

7. Check stroke of direct clutch piston (C2).

- Install the input shaft assembly into the rear crankcase and position the indicator as shown.

- Apply compressed air (4 kg/cm?) and measure the piston stroke C2.

- Stroke: 1.49-1.91mm (0.059-0.075 inch)

If the stroke of the C2 piston is not correct, select a different flange.

- Flange thickness type: 4.0mm (0.157 inch), 4.2 mm (0.165"), 4.4 mm (0.173 inch)

Attention! Protective goggles should be worn when working with compressed air to prevent injury to the eyes.

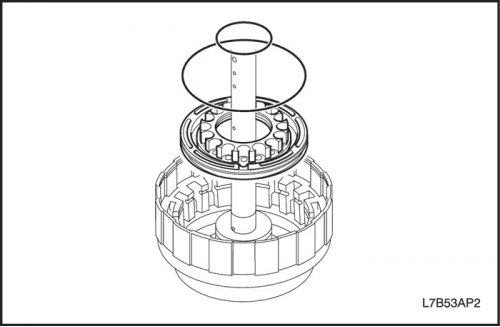

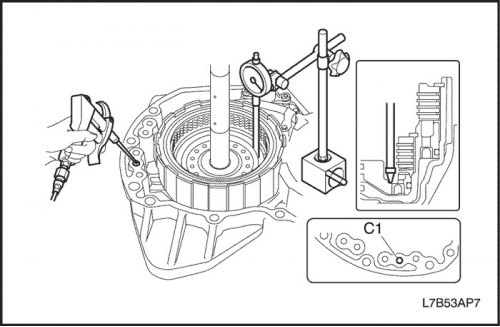

8. Check forward clutch piston stroke (C1).

- Install the input shaft assembly into the rear crankcase and position the indicator as shown.

- Apply compressed air (4 kg/cm?) and measure the piston stroke C1.

- Stroke: 0.71-1.09mm (0.028-0.043 inch)

If the stroke of the C1 piston is not correct, select a different flange.

- Flange thickness type: 5.0mm (0.197 inch), 5.2 mm (0.205 inch), 5.4 mm (0.213 inch)