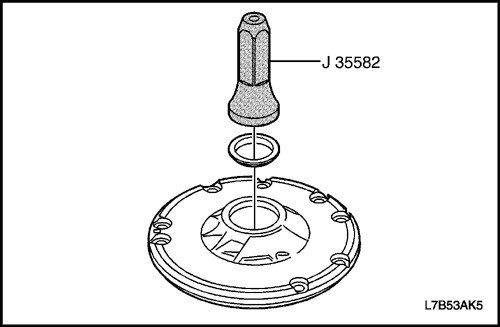

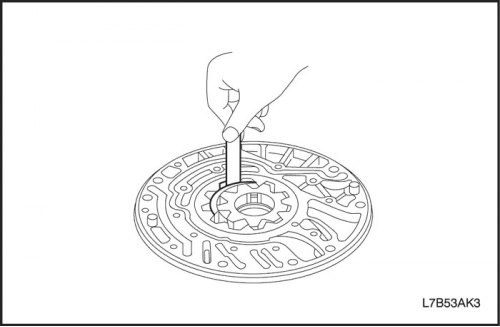

- Using a dial gauge, measure the inside diameter of the oil pump housing bushing.

Inner diameter:

- Standard: 38.113-38.138mm (1.500-1.501 inches)

- Max: 38.188mm (1.503 inches)

Important: Measure in different places and take the average. If the measurement value is greater than the maximum, replace the oil pump housing with a new one.

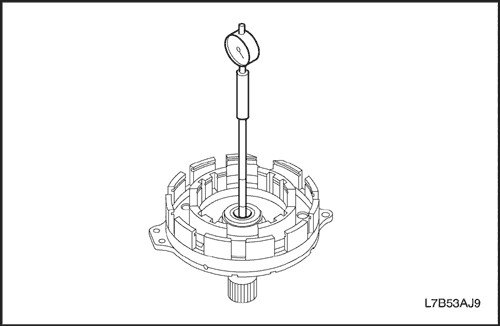

2. Check the reactor shaft bushing.

- Using an indicator, measure the inside diameter of the reactor shaft sleeve.

Inner diameter:

- Standard: 22.201-22.227 mm (0.874-0.875 inches)

- Maximum: 22.257 mm (0.876")

Important: Measure in different places and take the average. If the measurement value is greater than the maximum, replace the reactor shaft with a new one.

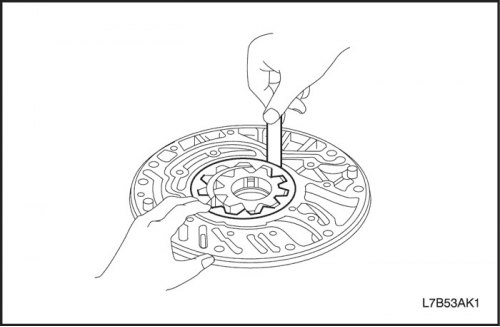

3. Check clearance between gear and housing.

- Slide the outer gear all the way to the housing wall. Measure the gap with a feeler gauge.

Gap between gear and housing:

- Standard: 0.075-0.150mm

- Maximum: 0.200mm

4. Check the clearance between the tooth heads of both gears.

- Using a feeler gauge, measure between the teeth of the drive gear and the crescent of the pump casing.

The gap between the heads of the teeth of the drive gear:

- Standard: 0.013-0.292mm (0.001-0.011 inch)

- Maximum: 0.342mm (0.013 inch)

- Using a feeler gauge, measure between the driven gear teeth and the crescent of the pump housing.

The gap between the heads of the teeth of the driven gear:

- Standard: 0.004-0.248mm (0.0001-0.010 inch)

- Maximum: 0.298mm (0.012 inch)

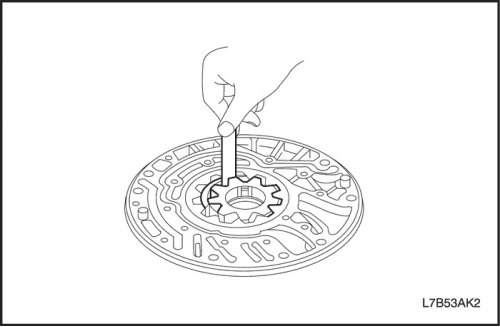

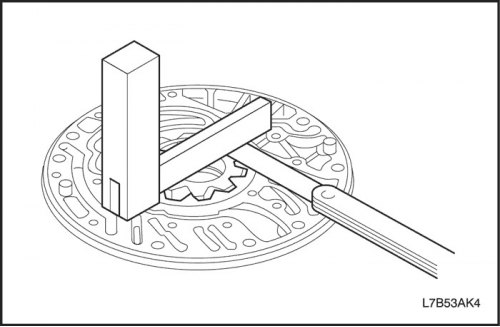

5. Check the end clearance of both gears.

- Using a steel ruler and feeler gauge, measure the end clearance of both gears.

End gap between driving and driven gears:

- Standard: 0.03-0.05mm (0.001 - 0.002 inches)

- Maximum: 0.10mm (0.004 inch)