Note: The intake manifold consists of an upper section and a lower section. Removing the upper intake manifold is only required for some jobs (e.g. maintenance of fuel injectors/spark plugs), while some other jobs require the removal of both the top and bottom assembly (e.g. cylinder head maintenance). If only the top manifold needs to be removed, see part «Upper intake manifold» in this section.

Removal procedure

1. Relieve pressure in the fuel system. See Part 1F3, Engine Controls - HFV6 3.2L.

2. Disconnect the negative battery cable.

3. Remove intake duct.

4. Remove the decorative engine cover. See «Decorative engine cover» in this section.

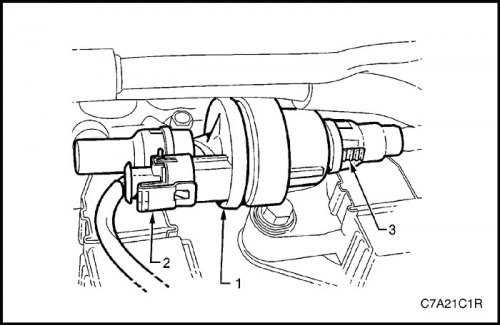

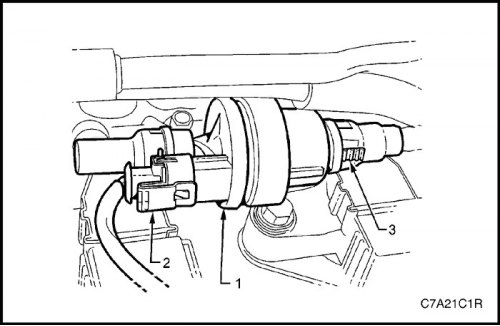

Attention! When disconnecting the throttle body wiring harness, the following precautions must be observed.

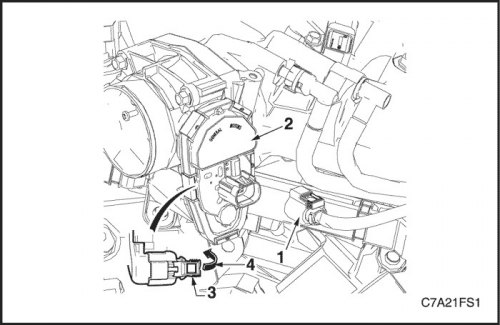

- To disconnect the connector (1) throttle body harness (2) do not use any mechanical tools such as a screwdriver.

- Taking away the lock (3) throttle cable connector, care must be taken not to disconnect it from the connector.

- Do not pull on the connector wires.

5. Take away the lock (3) throttle cable connector.

6. Pressing the connector lock in the direction of the arrow (4), disconnect the throttle body wiring connector.

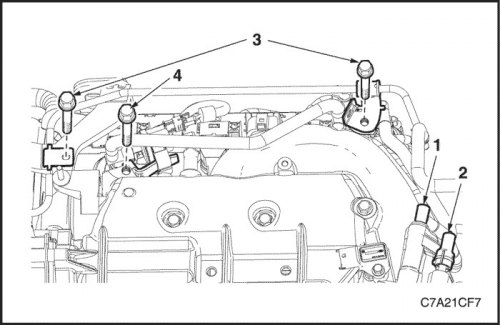

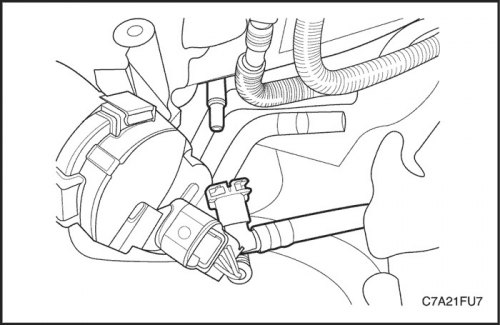

7. Disconnect the hose (1) forced crankcase ventilation and vacuum hose (2) purge adsorber SUPS.

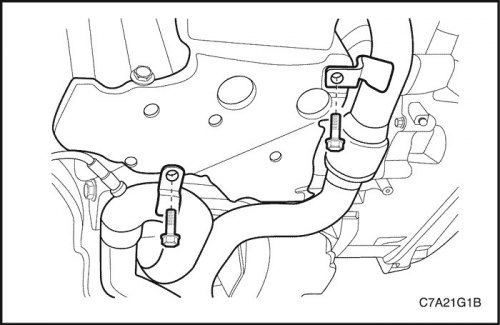

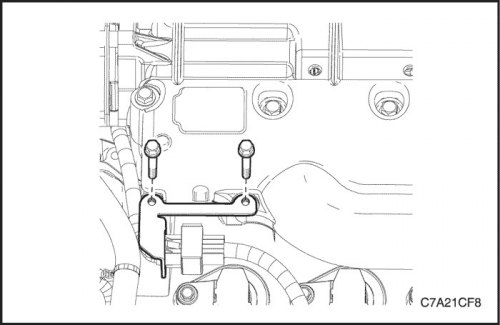

8. Remove bolts (3) fixing the pipe bracket between the expansion tank and the water outlet.

9. Remove bolt (4) fastening the bracket for the EVAP adsorber purge valve.

10. Disconnect the wiring harness connector from the intake manifold adjustment valve (IMTC).

11. Remove the engine wiring harness connector mounting bracket.

12. Move from the upper intake manifold all parts that are close to it.

Attention! Seal the opening of the fuel supply hose after removal to prevent dirt and other substances from entering the fuel system.

13. Disconnect the fuel line from the fuel rail.

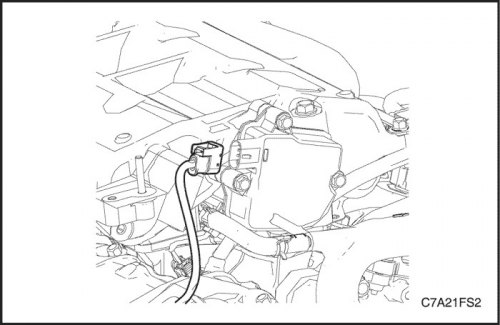

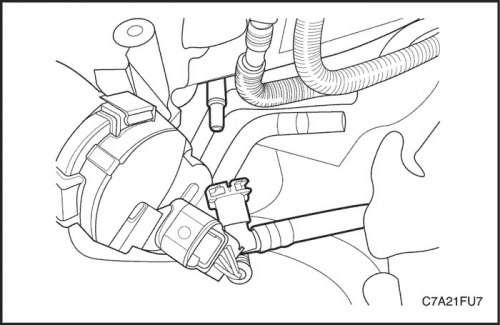

14. Disconnect wiring harness connector (2) from the EVAP valve (1).

15. Disconnect the quick connector (3) at the rear of the EVAP valve, proceeding in the following sequence:

- A. Squeeze the two ribbed tabs together, push the quick release towards the valve, and then pull back to disengage.

- b. Seal both open ends to prevent foreign material from entering.

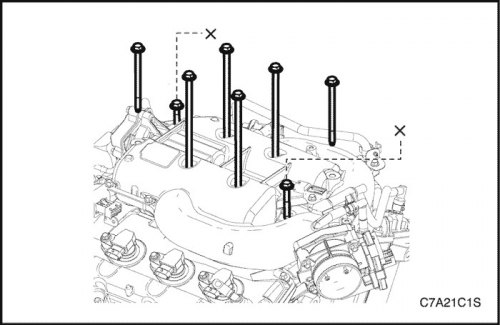

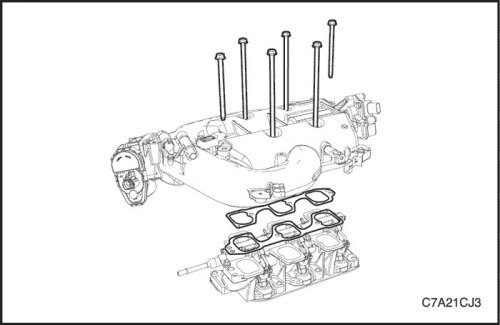

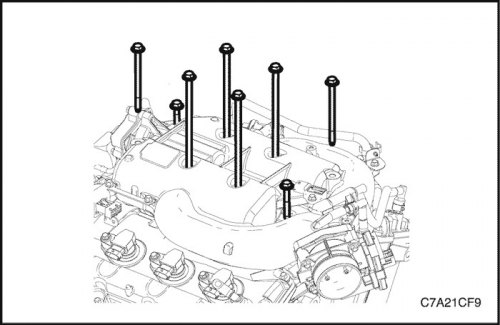

16. Remove four long (1) intake manifold bolt assembly to cylinder heads.

Attention! Do not loosen or remove the shortest bolts (X), connecting the upper and lower intake manifolds.

17. Take off two short (2) bolts securing the lower intake manifold to the cylinder heads.

Attention! After removing the intake manifold, plug each of the cylinder head intake ports with a lint-free cloth to prevent foreign material from entering them.

18. Remove the upper and lower intake manifold assemblies from the engine.

19. Remove the gasket between the lower intake manifold and cylinder heads.

20. Remove the upper intake manifold to lower intake manifold bolts.

21. Remove the upper intake manifold from the lower one.

Attention! Do not reuse the gaskets between the upper and lower intake manifolds.

22. Remove and discard the gaskets located between the upper and lower intake manifolds.

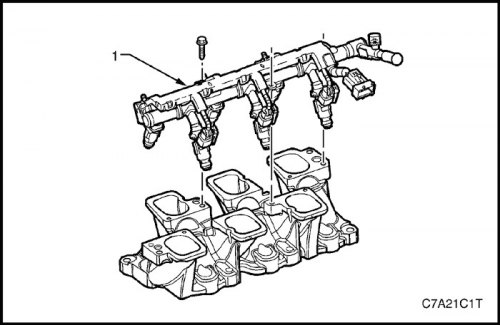

Attention! When removing the fuel rail and injectors assy (1) the following precautions must be observed:

- A. Care must be taken not to damage the spray tips of the injectors and the wiring harness connector pins when removing the fuel rail and injector assembly.

- b. After removal, it is necessary to lay the fuel rail with injectors as an assembly on the support.

- c. Seal all fuel lines and manifold openings after removal to prevent dirt and other substances from entering the fuel system.

23. Remove the fuel rail and injector assembly, if required. See Part 1F3, Engine Controls - HFV6 3.2L.

Clear

Attention! Since the intake manifold is made of aluminum alloy, do not use wire brushes and steel scrapers to clean it, because. this may damage the sealing surfaces. It is preferable to use wooden or plastic scrapers.

1. Clean mating surfaces, removing all gasket residues.

2. Clean manifold with suitable solvent.

3. Dry the components of the gas distribution mechanisms with compressed air.

Inspection

1. Inspect the intake manifold, checking for the following faults:

- Damaged sealing or mating surfaces.

- Damaged lower intake manifold gasket.

- Damaged or excessively dirty threaded or through holes.

- Cracked or damaged intake manifold housing.

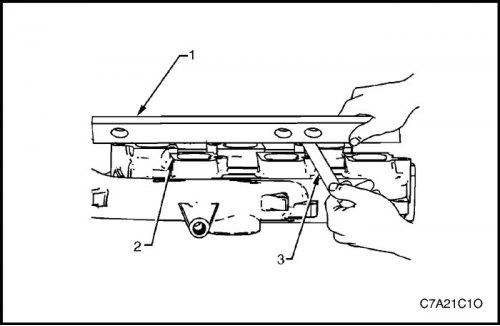

2. Lay the ruler (1) across the sealing surface (2) upper intake manifold.

3. With a probe (3) measure the gap between the manifold and the ruler.

4. If the gap between the top manifold sealing face and the bar is greater than the specified maximum warp, replace the manifold.

- Upper manifold max buckling: 0.05mm

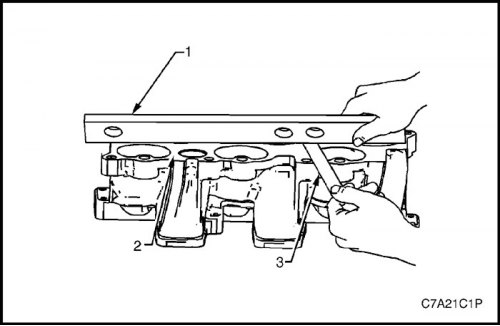

5. Lay the ruler (1) across the sealing surface (2) lower intake manifold.

6. With a probe (3) measure the gap between the manifold and the ruler.

7. If the gap between the bottom manifold sealing face and the bar is greater than the specified maximum warp, replace the manifold.

- Lower manifold maximum warpage: 0.05mm

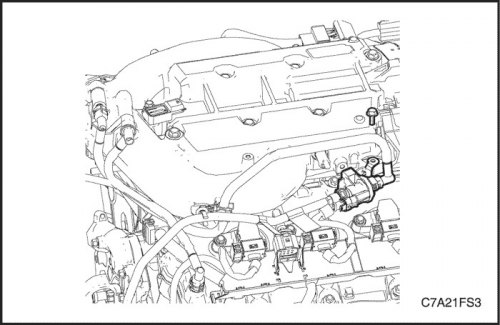

Installation procedure

1. Install the fuel rail and injector assemblies, if required. See Part 1F3, Engine Mechanical - HFV6 3.2L.

2. Install the lower intake manifold to the cylinder head.

Tighten

Tighten the lower intake manifold-to-cylinder head bolts to 23 Nm (17 lb-ft).

3. Install the upper intake manifold onto the lower one and onto the cylinder head.

Tighten

Tighten the lower intake manifold mounting bolts to the lower torque 23 Nm (17 lb-ft).

Tighten the upper intake manifold-to-cylinder head bolts to 23 Nm (17 lb-ft).

4. Connect the fuel injector connector.

5. Connect the fuel supply line to the fuel rail.

6. Connect the EVAP canister purge valve connector and quick connector.

7. Connect the IMTC connector.

8. Connect throttle connector.

9. Install the EVAP canister purge valve bracket bolt.

10. Install the pipe bracket bolts between the expansion tank and the water outlet.

11. Connect the EVAP vacuum hose and the positive crankcase breather hose to the upper intake manifold.