Necessary equipment

EN-48243 Engine Removal/Installation Rack Assembly

EN-48244 Rack bracket for engine removal/installation assembly

Removal procedure

1. Remove the fuel pump fuse.

2. Start the engine. After stopping the engine, crank the engine for 10 seconds to relieve pressure in the fuel system.

3. Drain the engine oil.

4. Drain the engine coolant. See Part 1D3, Engine Cooling HFV6 3.2L.

5. Drain the oil from the power steering.

6. Drain transmission oil. See Section 5A, AISIN 55-51LE Automatic transaxle with final drive assembly or Section 5B, Five-speed final drive assembly (D33).

7. Discharge the air conditioning system, if equipped. Follow See Section 7B, Heating, Ventilation, and Air Conditioning Control.

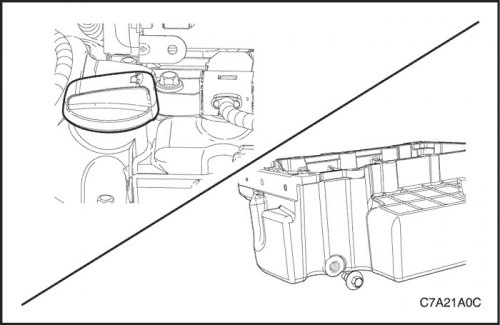

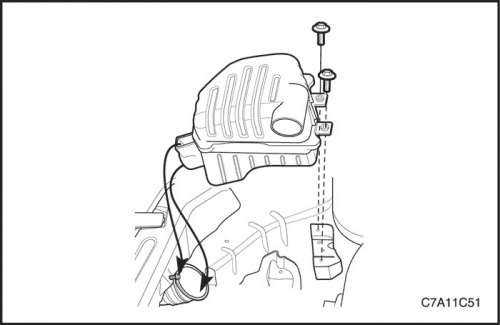

8. Remove the decorative engine cover. See «Decorative engine cover» in this section.

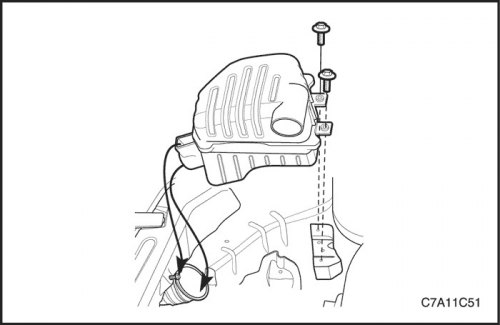

9. Remove the air filter assembly. See «Air filter assembly» in this section.

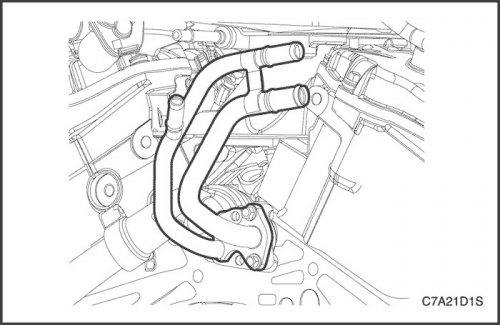

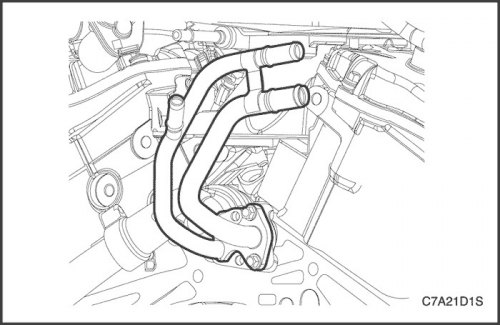

10. Disconnect the upper radiator hose from the water outlet.

11. Disconnect the water hose from the water outlet.

12. Disconnect the lower radiator hose from the water pipe.

13. Disconnect the heater inlet/outlet hose from the heater inlet/outlet pipe.

14. Disconnect the power steering hoses from the power steering fluid reservoir. See Section 6A, Power Steering System.

15. Remove the battery. See Part 1E3, Engine Electrical - HFV6 3.2L.

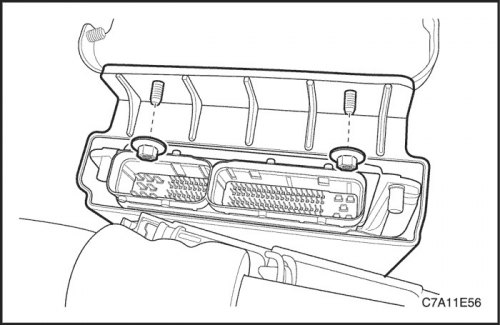

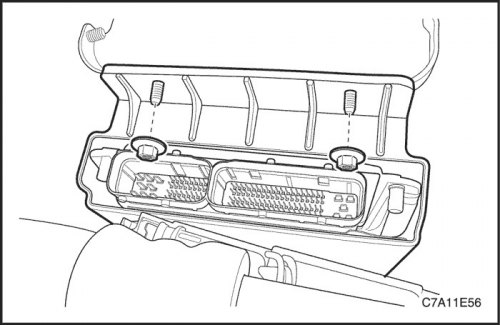

16. Remove the ECM. See Section 1F3, Engine Controls - HFV6 3.2L.

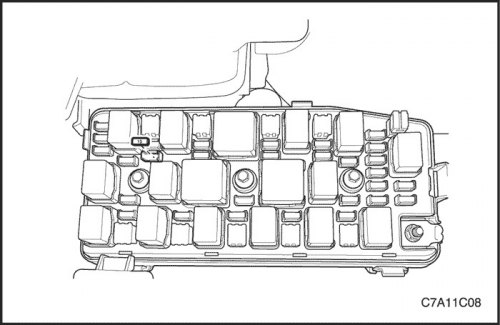

17. Disconnect the main cable from the engine fuse box.

18. Disconnect the ground terminal wiring harness.

19. Disconnect fuel line.

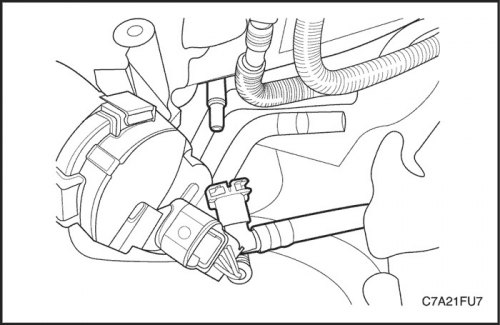

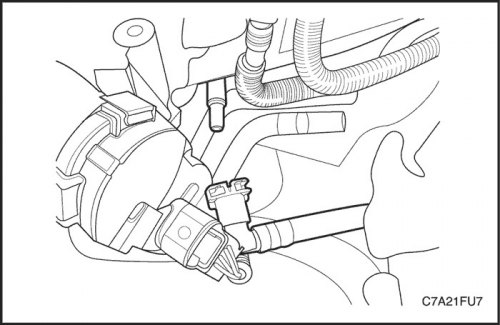

20. Disconnect the front EVAP canister purge hose from the EVAP canister purge solenoid valve.

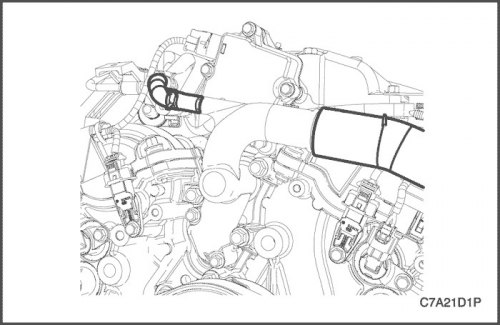

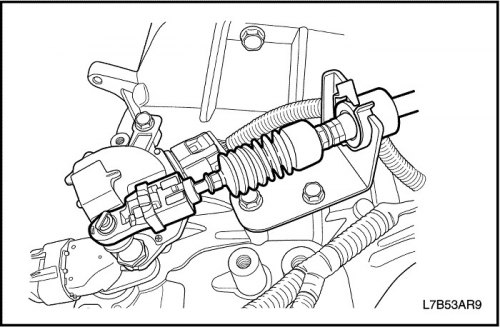

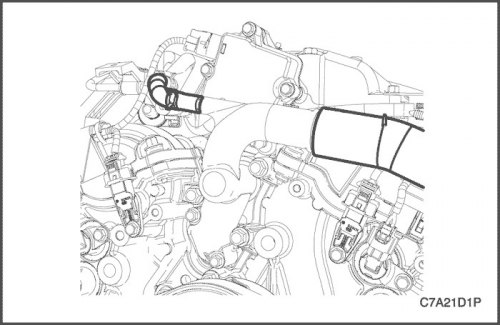

21. Disconnect the brake booster vacuum hose from the rear cylinder head cover.

22. Disconnect the transmission mode sensor electrical connector. See Section 5A, AISIN 55-51LE Automatic transaxle with final drive assembly or Section 5B, Five-speed final drive assembly (D33).

23. Disconnect the shift control cable from the transmission.

24. Disconnect the transmission coolant oil pipe from the radiator. See Section 5A, "Automatic transmission complete with final drive AISIN 55-51".

25. Disconnect the transmission coolant oil pipe from the radiator. Look Section 5B, Five-Speed Manual Transaxle with Final Drive Assembly (D33).

26. Disconnect the stabilizer link. See Section 2D, Rear Suspension.

27. Disconnect the rod end connection. See Section 2D, Rear Suspension.

28. Disconnect the tie rod connection. See Section 2D, Rear Suspension.

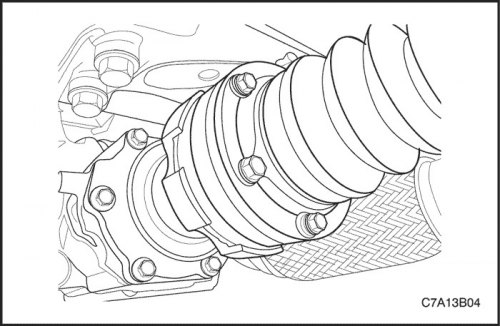

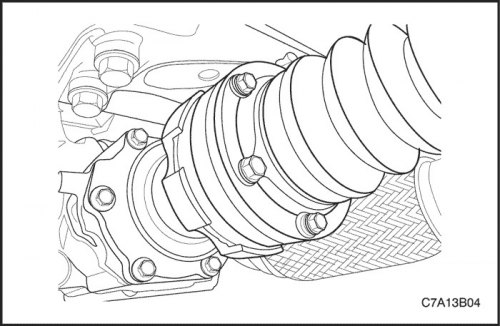

29. Dismantle the left and right axle shafts. See Section 3A, Front Drive Axle or Section 3B, Rear Drive Axle.

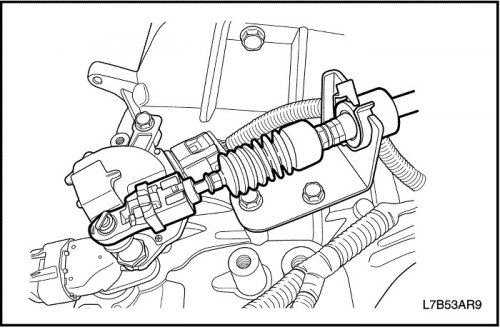

30. Disconnect the intermediate shaft from the power steering gear. See Section 6C, Power steering.

31. Remove cardan shaft. See Section 3B, Rear Drive Axle.

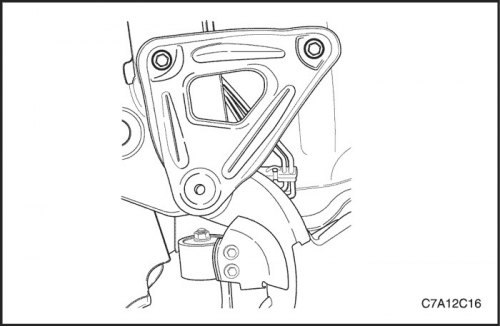

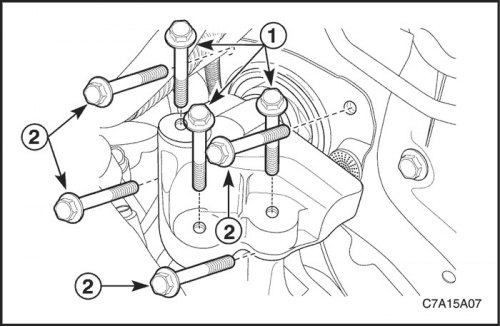

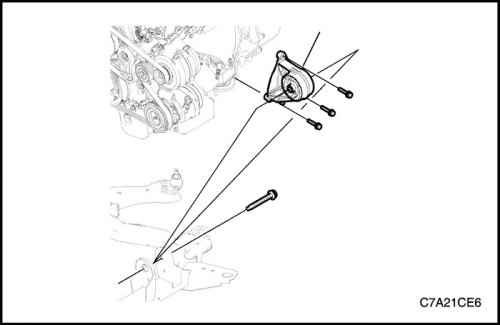

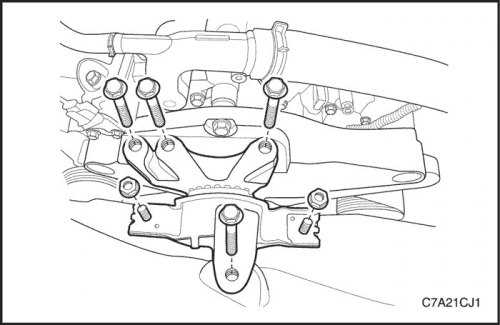

32. Remove the support bracket bolts from the rear of the support.

33. Remove the support bracket bolts from the front of the support.

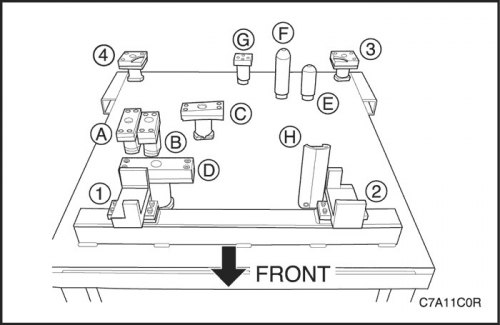

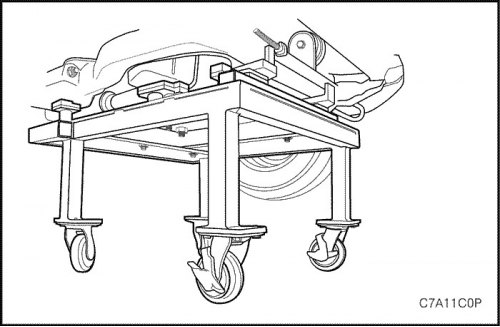

Attention! Verify that all components are installed exactly in the correct position on the EN-48243 engine removal/installation rack or on the EN-48244 bracket as shown.

- 1~4: Support bracket

- A: Diesel engine oil pan bracket

- B: FAM II 2.4D engine oil pan bracket

- C&D: HFV6 3.2L Engine Oil Pan Bracket

- E: Bracket for manual transmission with final drive assembly

- F: Bracket for automatic transmission with final drive assembly

- G: Transfer case bracket ((M/T and A/T)

- H: Gearbox suspension bracket assembly (M/T and A/T)

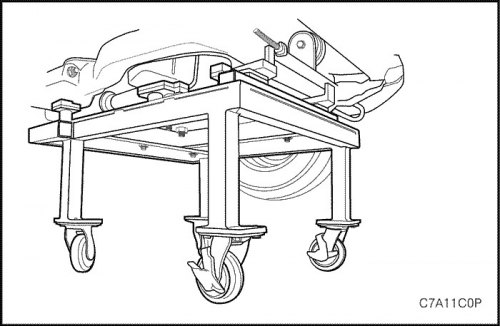

Attention! Lower the vehicle enough to take the load off the engine mount and transaxle assembly, otherwise damage to the suspension and rack/rack bracket failure may occur.

34. Lower the vehicle and place the engine assembly on the EN-48243 engine install/remove rack assembly with the EN-48244 rack bracket to support.

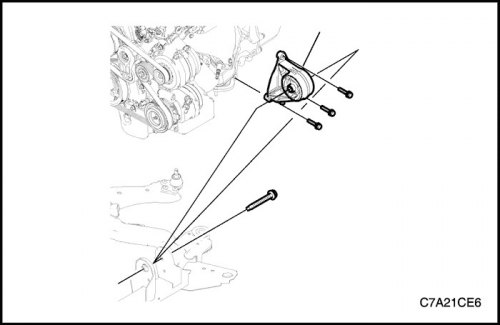

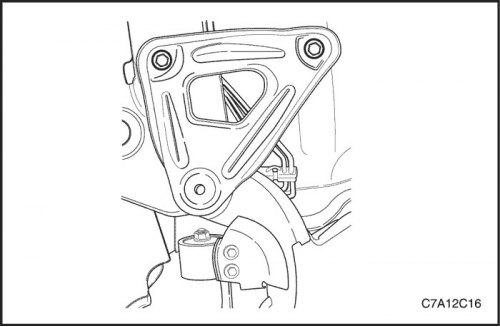

35. Remove the engine mount. See «Engine mount» in this section.

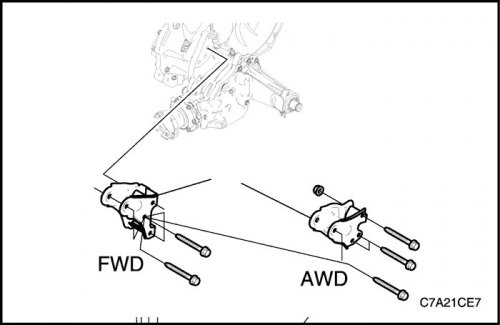

36. Remove the transmission mount assembly with final drive. See «Gearbox suspension with final drive, assy» in this section.

Attention! Make sure all wires, connectors and hoses are disconnected from the engine and transaxle assembly.

37. Raise the vehicle for free removal of the engine and transaxle assembly.

38. Remove the engine and transaxle assembly from the vehicle

39. Place a lifting device on the engine support bracket and raise the engine assembly so that the front and rear transaxle mounts are unloaded.

40. Remove the front transmission suspension with final drive assembly from the support. See «Gearbox Front Suspension with Final Drive Assembly» in this section.

41. Remove the rear suspension of the gearbox with final drive assembly from the support. See «Rear Suspension Gearbox with Final Drive Assembly» in this section.

42. Raise the engine assembly and remove the support from the engine and transaxle assembly.

43. Separate the cylinder block from the transaxle assembly as follows.

- A. Remove the starter.

- b. Loosen the torque converter bolts.

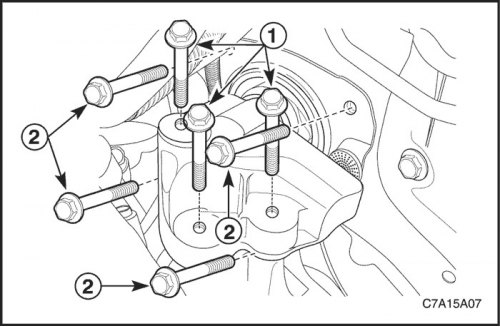

- c. Unscrew the fixing bolts connecting the gearbox with final drive assembly to the engine block.

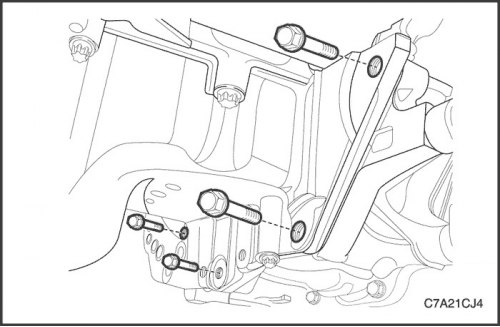

- d. Loosen the mounting bolts connecting the oil flange to the transaxle assembly.

Installation procedure

1. Install torque converter bolts, if required.

Tighten

Tighten torque converter bolts to 65 Nm (48 lb-ft).

2. Install the transaxle assembly to the engine block, if required.

Tighten

Tighten the oil sump flange-to-transaxle bolts to 50 Nm (37 lb-ft).

Tighten the bolts securing the gearbox with final drive assembly to the cylinder block (upper side of gearbox x 3, starter side x 1, rear side of gearbox x 1) torque 50 Nm (37 lb-ft).

Attention! Verify that all components of the EN-48243 Motor Assembly Removal/Installation Rack are aligned exactly with the EN-48244 Rack Bracket.

3. Install the engine and gearbox with final drive assembly on the support.

Attention! Before tightening the transaxle front mount pinch bolt, move the engine assembly back and forth or side to side for proper installation.

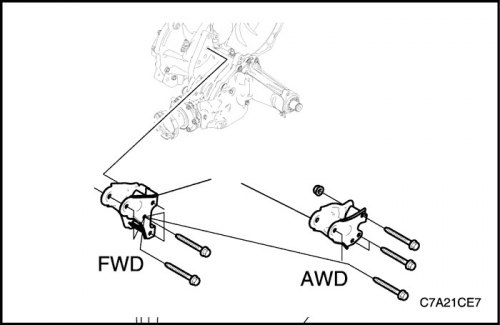

4. Install the transaxle front suspension assembly.

Tighten

Tighten the transaxle front mount retaining bolts to 50 Nm (37 lb-ft).

Tighten the pinch bolt of the front suspension of the gearbox with final drive assembly to the support to a torque of 90 Nm (66 lb-ft).

Attention! Before tightening the transaxle rear mount pinch bolt, move the engine assembly back and forth or side to side for proper installation.

5. Install the transaxle rear mount assembly to the engine block.

Tighten

Tighten the transaxle rear mount retaining bolts to 90 Nm (66 lb-ft).

Tighten the pinch bolt of the rear suspension of the gearbox with final drive assembly to the bracket to 90 Nm (66 lb-ft).

6. Raise the car.

7. Lower the vehicle and place the engine and transaxle assembly connected to the support on the EN-48243 engine install/remove rack assembly with EN-48244 rack bracket in the vehicle.

8. Establish a suspension bracket of the check point with the main transfer in gathering. See «Gearbox suspension with final drive, assy» in this section.

Tighten

Tighten the transaxle mount retainer bolts to 37 Nm (27 lb-ft).

Tighten the locking bolts of the gearbox suspension bracket with final drive assembly to 50 Nm (37 lb-ft).

9. Install the engine mount. See «Engine mount» in this section.

Tighten

Tighten the retaining bolt of the engine mount frame side bracket to 100 Nm (74 lb-ft), and nuts with a torque of 90 Nm (66 lb-ft).

Tighten the engine mount adapter retaining bolts to 50 Nm (37 lb-ft).

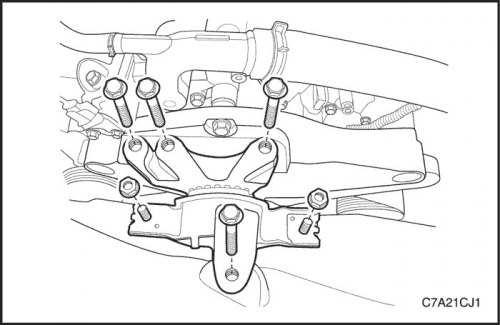

10. Install the bolts securing the support bracket to the front of the support.

Tighten

Tighten the support mounting bolts to 155 Nm (114 lb-ft).

11. Tighten the support bracket bolts to 50 Nm (37 lb-ft).

12. Attach the stabilizer bar. See Section 2D, Rear Suspension.

13. Attach the tie rod end. See Section 2D, Rear Suspension.

14. Connect the tie rod. See Section 2D, Rear Suspension.

15. Install the left and right axle shafts. See Section 3A, Front Drive Axle or Section 3B, Rear Drive Axle.

16. Attach the intermediate shaft to the power steering gear. See Section 6C, Power steering.

17. Install driveshaft. See Section 3B, Rear Drive Axle.

18. Connect the transmission mode sensor electrical connector. See Section 5A, AISIN 55-51LE Automatic transaxle with final drive assembly or Section 5B, Five-speed final drive assembly (D33).

19. Connect the shift control cable to the transmission.

20. Connect the oil pipe of the transmission cooling system to the radiator. See Section 5A, "Automatic transmission complete with final drive AISIN 55-51".

21. Connect the power steering fluid coolant return pipe. See Section 6A, Power Steering System.

22. Connect fuel line.

23. Connect the front EVAP canister purge hose to the EVAP canister purge solenoid valve.

24. Connect the brake booster vacuum hose to the rear cylinder head cover.

25. Install battery. See Part 1E3, Engine Electrical - HFV6 3.2L.

26. Install the ECM. See Section 1F3, Engine Controls - HFV6 3.2L.

27. Connect the main cable of the engine fuse box.

28. Connect the wire harness to the ground terminal.

29. Connect the lower radiator hose to the water pipe.

30. Connect the heater inlet/outlet hose to the heater inlet/outlet pipe.

31. Connect the power steering hoses to the power steering fluid reservoir. See Section 6A, Power Steering System.

32. Disconnect the upper radiator hose from the water outlet.

33. Disconnect the water hose from the water outlet.

34. Remove the decorative engine cover. See «Decorative engine cover» in this section.

35. Remove the air filter assembly. See «Air filter assembly» in this section.

36. Install the fuel pump fuse.

37. Fill the crankcase with engine oil.

38. Refill the engine cooling system. See Part 1D3, Engine Cooling HFV6 3.2L.

39. Refill the power steering system and bleed the system. See Section 6A, Power Steering System.

40. Charge the air conditioning refrigeration system, if equipped. Follow See Section 7B, Heating, Ventilation, and Air Conditioning Control.

41. Check for leaks and unusual sounds and that all fluids are at the correct level.