Removal procedure

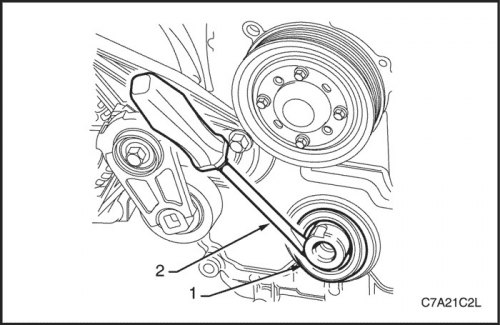

1. Turn the accessory drive belt tensioner clockwise to decrease belt tension.

2. While holding the tensioner in a position that provides reduced tension, disconnect the belt.

3. Remove the starter. See Part 1E3, Engine Electrical - HFV6 3.2L.

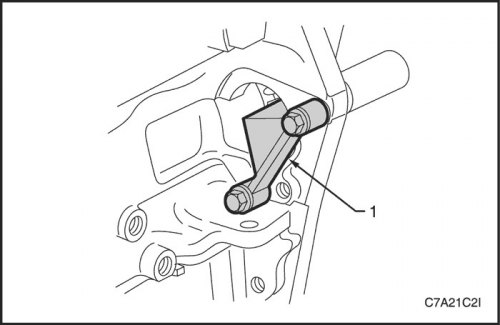

4. Install fixture EN-46106 (1) on the starter hole to prevent the camshaft from rotating.

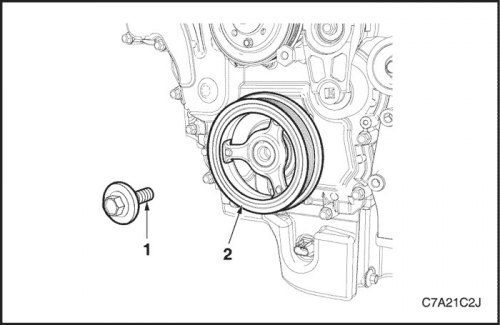

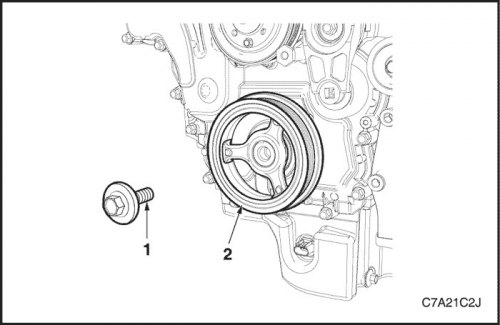

5. Remove bolt (1) pulley mounting (2) crankshaft to crankshaft.

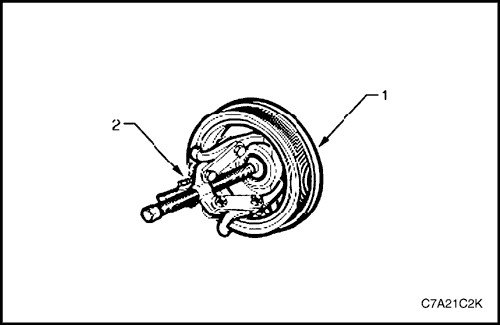

6. Remove crankshaft pulley assembly (1) from the crankshaft using a J-41816 3-jaw puller (2) or equivalent.

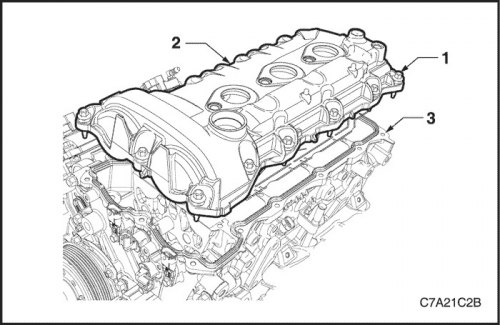

7. Using any tool with a flat blade (2), carefully remove the front seal from the front cover (1) crankshaft.

Cleaning and inspection

1. Clean the crankshaft pulley assembly using a commercially available suitable non-corrosive cleaning solvent and a soft bristled brush.

2. Dry the crankshaft pulley assembly with compressed air.

3. Inspect the crankshaft pulley assembly for the following faults:

- Wear or damage to the inner surface in contact with the crankshaft.

- Wear, grooves or scratches on the sealing surface.

- Wear, separation of the base material from the base and general deterioration of the rubber ring between the hub and the pulley.

- Pulley guide ribs damaged.

Installation procedure

Attention! Do not lubricate the front crankshaft oil seal or the sealing surfaces of the crankshaft pulley. The crankshaft pulley must be installed on a dry seal.

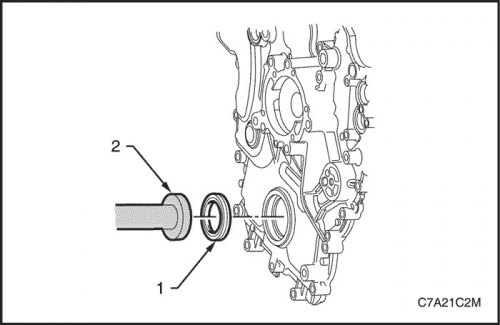

1. Using tool J-29184 to install the crankshaft front oil seal (2) and a suitable hammer, install a new front oil seal (1) crankshaft so that it is completely seated in the socket of the front cover.

2. Lubricate the crankshaft pulley hub bore.

3. Install the crankshaft pulley on the shaft, but not completely.

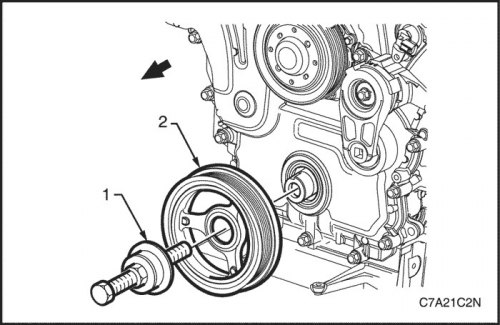

Attention! To avoid damage to the threads of the crankshaft, J-41998-B pulley installation tool must be fully inserted into the crankshaft (1), before pressing in the pulley and balancer assembly.

4. Using tool J-41998-B (1), fully install the pulley on the crankshaft.

5. Lubricate the threads of the new stop bolt (1) fasten the crankshaft pulley with Loctite 272 or equivalent.

6. Install the crankshaft pulley retaining bolt.

Tighten

Tighten the crankshaft pulley assembly retaining bolt to 100 Nm (74 lb-ft) and turn the bolt another 150°using the KM-470-B angle torque indicator.

7. Install starter. See Part 1E3, Engine Electrical - HFV6 3.2L.

8. Install the auxiliary drive belt.