Removal procedure

Bank 1

1. Remove the cylinder head cover for cylinder bank 1. «cylinder head cover» in this section.

2. Remove the camshaft timing actuators for bank 1 camshafts. «Camshaft control actuator assembly» in this section.

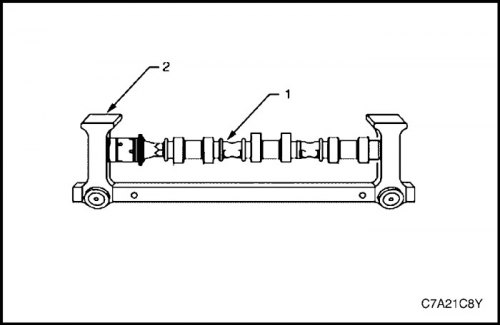

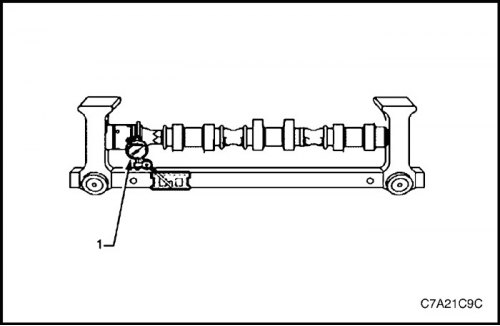

3. Remove fixture EN 46105-1 (1) from camshafts (2) cylinder bank 1.

Note: Tool EN-46105 was installed when removing the bank 1 camshaft timing actuators.

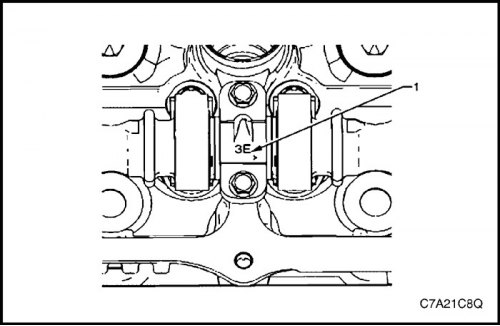

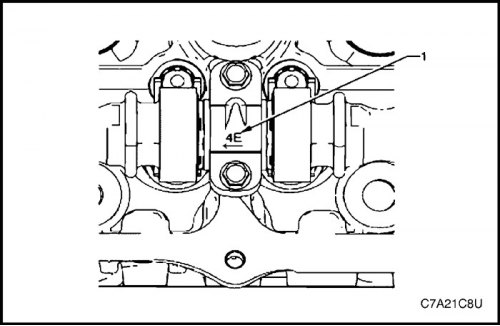

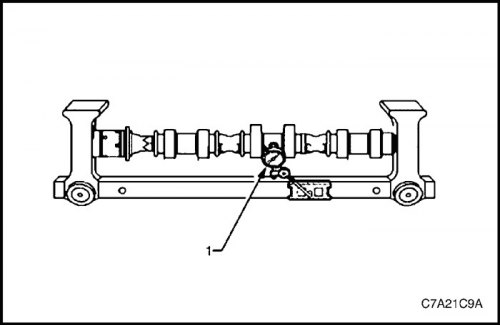

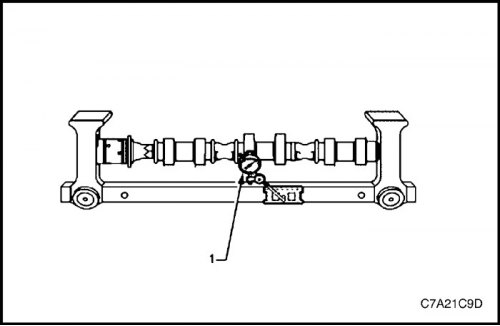

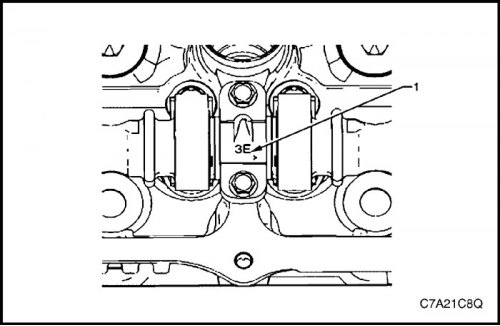

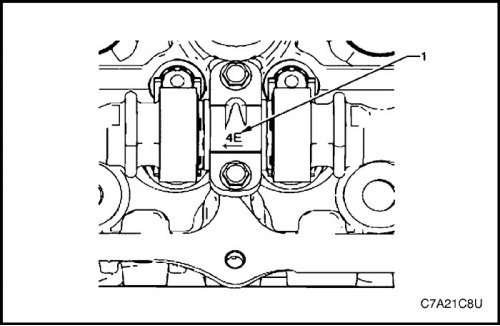

4. Pay attention to labeling (1) on the bearing caps. Each bearing cap is marked to identify its location. This marking contains the following information:

- The raised area must always be oriented towards the center of the cylinder head.

- The letter I stands for the intake camshaft.

- The letter E stands for exhaust camshaft.

- The number indicates the number of the shaft journal, counting from the front of the engine.

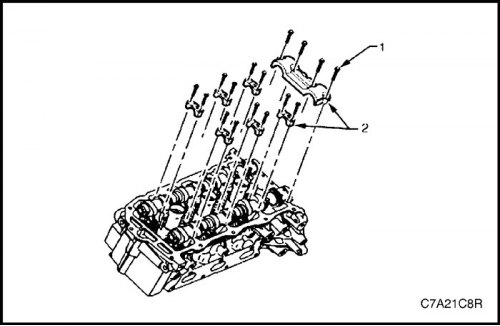

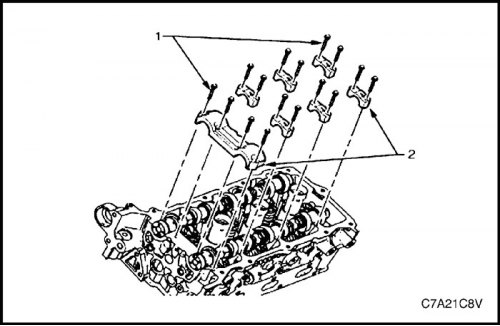

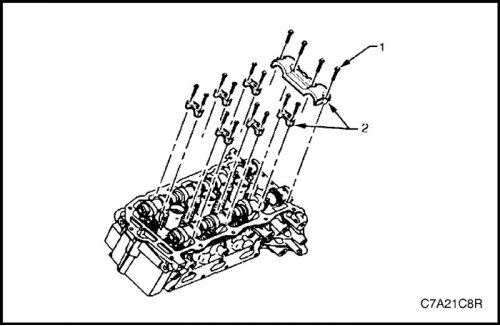

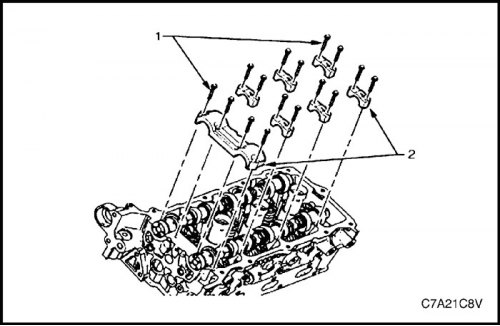

5. Remove screws (1) camshaft bearing caps and caps (2).

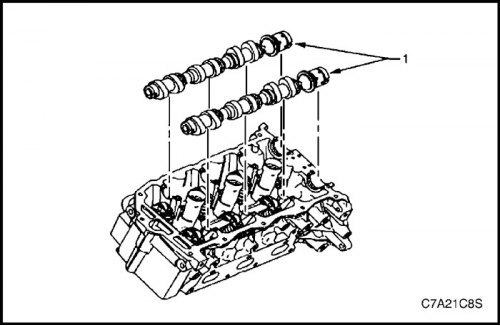

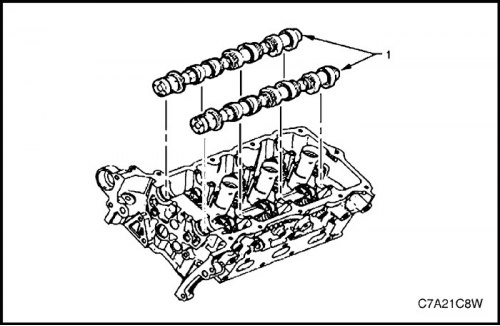

6. Remove camshafts (1).

7. Wash the camshaft in solvent and dry with compressed air.

Bank 2

1. Remove the camshaft timing actuators for bank 2 camshafts. «Camshaft control actuator assembly» in this section.

2. Remove tool EN-46105 - 1 (1) from the camshafts of cylinder bank 2.

Note: Tool EN-46105 was installed when removing the bank 2 camshaft timing actuators.

3. Pay attention to labeling (1) on the bearing caps. Each bearing cap is marked to identify its location. This marking contains the following information:

- The raised area must always be oriented towards the center of the cylinder head.

- The letter I stands for the intake camshaft.

- The letter E stands for exhaust camshaft.

- The number indicates the number of the shaft journal, counting from the front of the engine.

4. Remove screws (1) camshaft bearing caps and caps (2).

5. Remove camshafts (1).

6. Wash the camshaft in solvent and dry with compressed air.

Inspection

Camshaft Inspection

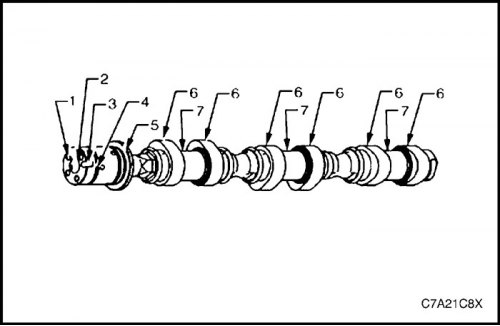

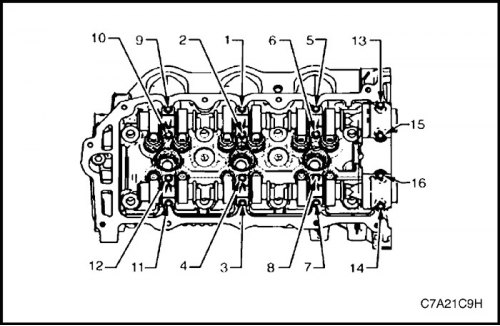

1. Check oil holes (1) to the valve timing actuator, checking for dirt or blockage.

2. Inspect threaded hole (2), while checking for damage.

3. Check mounting slot (3) for the variable valve timing actuator, checking for damage or wear.

4. Check sealing grooves (4) camshaft, checking for damage.

5. Check the hard surface (5) camshaft, checking for damage, dirt or blockage.

6. Inspect cams (6) and necks (7) camshaft, checking for the following faults:

- Too many scratches or chipping

- Color change due to overheating

- Deformation due to excessive wear, especially of the camshaft lobes

7. If the camshaft has any of the listed faults, then the shaft should be replaced.

Camshaft measurements

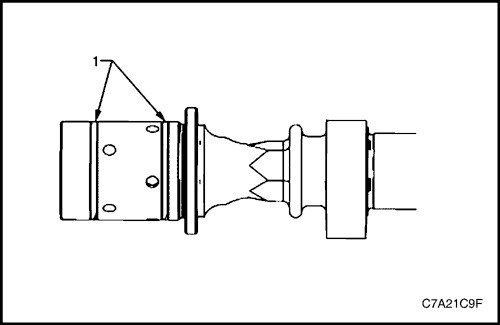

1. Installing the camshaft (1) into the appropriate device (2), take measurements to determine wear.

Attention! Any machining of the camshaft is not permitted.

Note: If the camshaft measurements are out of range, the camshaft must be replaced.

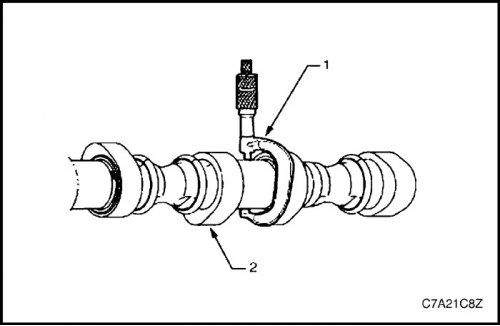

2. Measure the diameter and roundness of the neck (2) camshaft with micrometer (1).

3. Measure camshaft runout with a dial indicator (1).

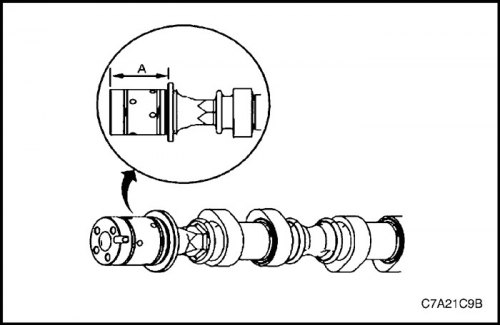

4. Measure the degree of wear along the width of the thrust pad using an inside micrometer (A).

5. Measure with a dial indicator (1) beating of the surface of the thrust wall of the camshaft.

6. Measure with a dial indicator (1) wear of the camshaft cams.

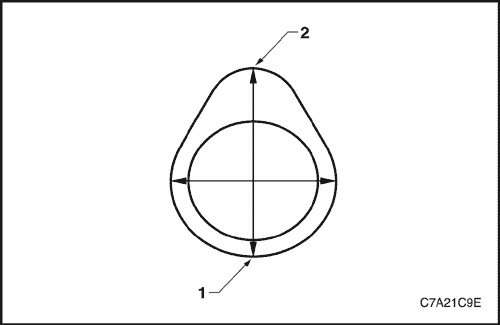

7. Set the tip of the dial indicator to the base circle (1) camshaft cam.

8. Set the indicator to zero.

9. Rotate the camshaft until the tip of the indicator is at the point farthest from the axis of rotation (2) cam. This value represents the amount of cam lift.

Installation procedure

Bank 1

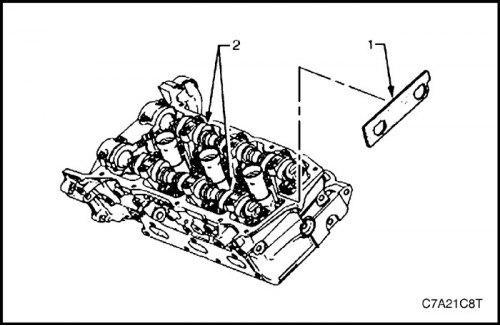

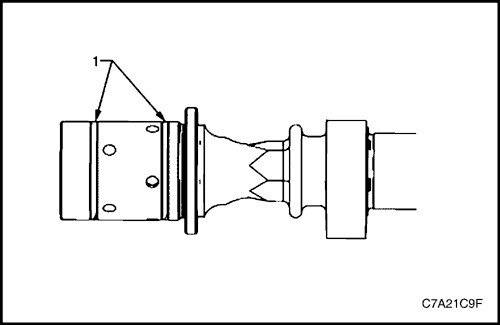

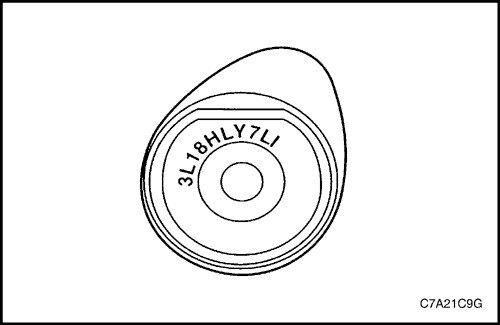

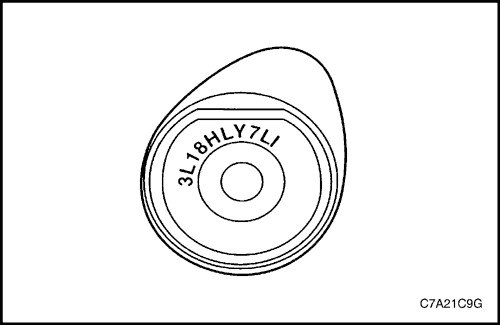

1. O-rings (1) camshaft must be in place in the grooves of the shaft.

2. When installing a camshaft, it is necessary to correctly determine its purpose. The corresponding marking is on the rear end of each camshaft. This marking contains the following information:

A. The first five positions indicate the date and time of manufacture.

- Example = 3L18H

b. Positions six through nine contain the production designation of the engine.

- LY7 = Alloytec190 engine

c. The last two positions indicate the position:

- LI = bank 2 intake.

- LE = cylinder bank 2, exhaust.

- RI = Bank 1, intake.

- RE = cylinder bank 1, exhaust.

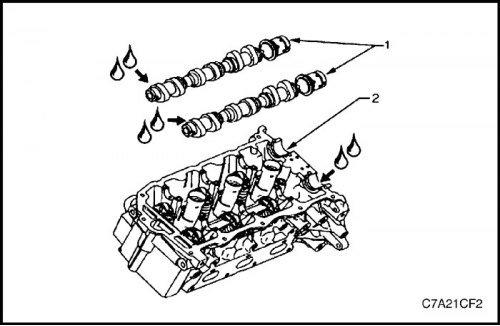

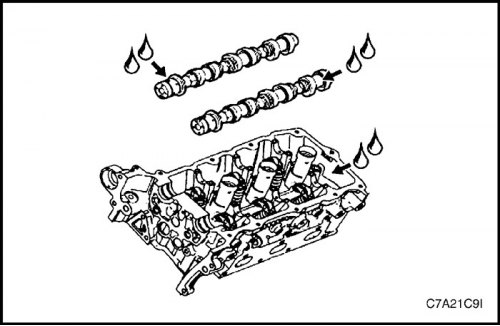

3. Lubricate necks generously with engine oil (1) camshafts and bearings (2) camshafts for cylinder bank 1.

4. Lubricate necks generously with engine oil (1) camshafts and bearings (2) camshafts for cylinder bank 1.

Note: Install the camshaft actuator bolts, but do not tighten them at this stage of the job.

5. The camshafts must be positioned so that their cams are in the neutral position and the flats on the rear ends of the bank 1 shafts are up and parallel (1) interface (2) with cylinder head cover.

6. Align the marks made before disassembly on the valve timing actuator of the exhaust camshaft of cylinder bank 1 and on the timing chain.

7. Align the pre-disassembly marks on the inlet camshaft camshaft actuator for cylinder bank 1 and on the timing chain.

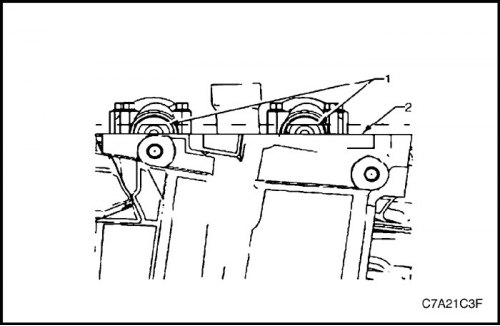

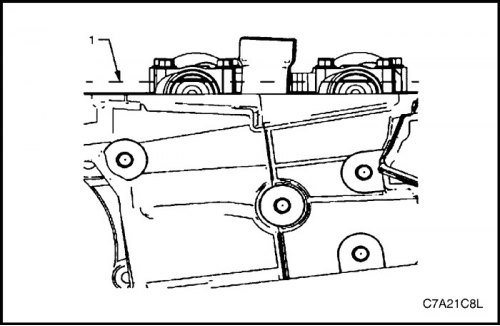

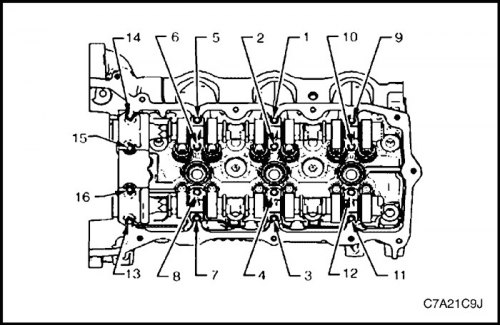

8. It is necessary to pay attention to the marking on the bearing caps of the camshafts of cylinder bank 1. Each bearing cap has a marking (1), defining its location. This marking contains the following information:

- The raised area must always be oriented towards the center of the cylinder head.

- The letter I stands for the intake camshaft.

- The letter E stands for exhaust camshaft.

- The numbers 1, 3, 5 indicate the position of the cylinder, counting from the front of the engine.

9. Lubricate the camshaft bearing caps liberally with engine oil.

10. Lubricate the camshaft bearing caps liberally with engine oil.

11. Install remaining covers (2) bearings with their alignment marks towards the center of the cylinder head.

12. Tighten all bolts by hand (3) camshaft bolt caps.

13. Install the camshaft bearing head screws.

Tighten

Tighten the camshaft bearing cap bolt to 10 Nm (89 lb-in.).

14. Loosen bolts 1 and 2 for intake camshaft center bearing cap and bolts 3 and 4 for exhaust camshaft center bearing cap.

15. Retighten bolts 1, 2, 3 and 4 for camshaft center bearing caps.

Tighten

Tighten the camshaft bearing cap bolt to 10 Nm (89 lb-in.).

16. Install the camshaft timing actuators for bank 1 camshafts. «Camshaft control actuator assembly» in this section.

Bank 2

1. O-rings (1) camshaft must be in place in the grooves of the shaft.

2. When installing a camshaft, it is necessary to correctly determine its purpose. The corresponding marking is on the rear end of each camshaft. This marking contains the following information:

A. The first five positions indicate the date and time of manufacture.

- Example = 3L18H

b. Positions six through nine contain the production designation of the engine.

- LY7 = Alloytec 190 engine

c. The last two positions indicate the position:

- LI = bank 2 intake.

- LE = cylinder bank 2, exhaust.

- RI = Bank 1, intake.

- RE = cylinder bank 1, exhaust.

3. Liberally lubricate the camshaft journals and camshaft bearings for bank 2 with engine oil.

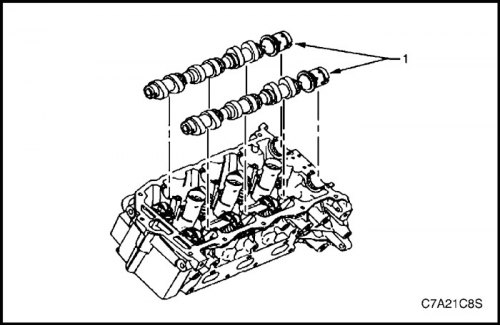

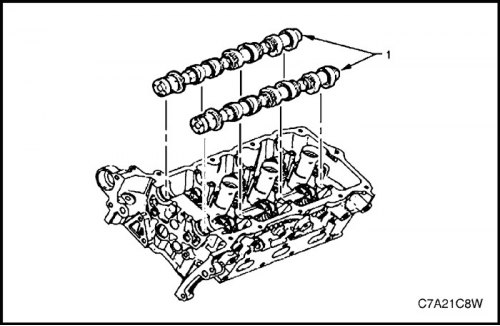

4. Position the camshafts (1) on the cylinder head and install the variable valve timing drives on the shafts.

Note: Install the camshaft actuator bolts, but do not tighten them at this stage of the job.

5. The camshafts must be positioned so that their cams are in the neutral position and the flats on the rear ends of the cylinder bank 2 shafts are up and parallel to the interface with the cylinder head cover.

6. Align the pre-disassembly marks on the bank 2 exhaust camshaft timing actuator and on the timing chain.

7. Align the pre-disassembly marks on the bank 2 intake camshaft timing actuator and the timing chain.

8. It is necessary to pay attention to the marking on the bearing caps of the camshafts of cylinder bank 2. Each bearing cap has a marking (1), defining its location. This marking contains the following information:

- The raised area must always be oriented towards the center of the cylinder head.

- The letter I stands for the intake camshaft.

- The letter E stands for exhaust camshaft.

- The numbers 2, 4, 6 indicate the position of the cylinder, counting from the front of the engine.

9. Lubricate the camshaft bearing caps liberally with engine oil.

10. Install cover (1) camshaft thrust bearing on the first journal of cylinder bank 2.

11. Install remaining covers (2) bearings with their alignment marks towards the center of the cylinder head.

12. Tighten all bolts by hand (3) camshaft bolt caps.

13. Install the camshaft bearing head screws.

Tighten

Tighten the camshaft bearing cap bolt to 10 Nm (89 lb-in.).

14. Loosen bolts 1 and 2 for intake camshaft center bearing cap and bolts 3 and 4 for exhaust camshaft center bearing cap.

15. Retighten bolts 1, 2, 3 and 4 for camshaft center bearing caps.

Tighten

Tighten the camshaft bearing cap bolt to 10 Nm (89 lb-in.).

16. Install the valve timing control actuators of the camshafts of a number of cylinders 2. See. «Camshaft control actuator assembly» in this section.