Removal procedure

1. Disconnect the negative battery cable.

2. Dismantle the engine assembly. Follow the point in this section.

3. Remove the timing belt front cover. See this section.

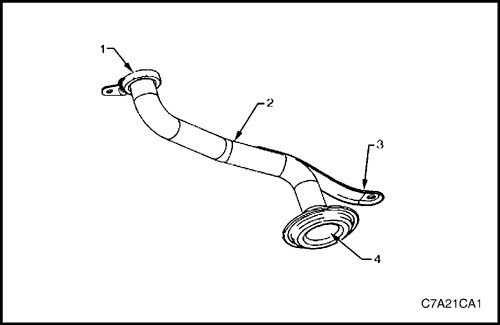

4. Remove the front exhaust pipe. See Part 1G3, Engine exhaust system.

5. Disconnect the oil level sensor connector.

6. Remove the oil filler cap to allow the oil to drain.

7. Remove the oil pan drain plug and drain the oil into a suitable container.

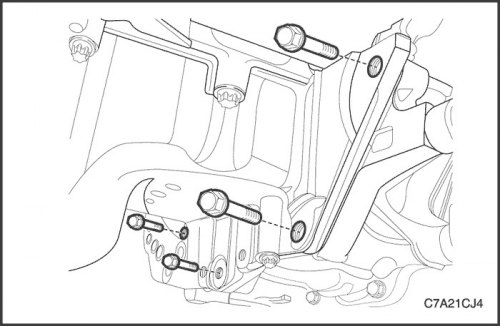

8. Remove the oil pan flange retaining screws to the transaxle assembly.

9. Remove the transfer case bracket bolts. See Part 5D. "Transfer case".

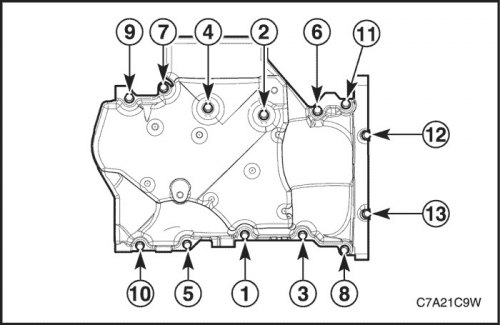

10. Remove two long bolts (12 and 13), with which the rear of the oil pan is attached to the crankshaft rear oil seal housing.

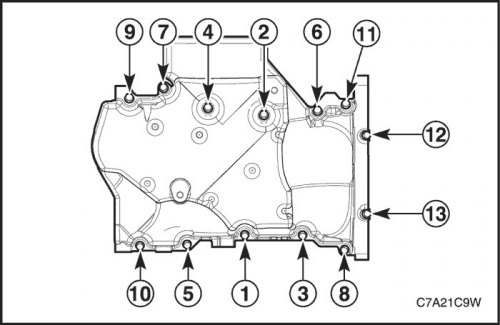

11. Remove eleven bolts (1st to 11th), with which the oil pan is attached to the cylinder block.

12. Using the support points located at the edges of the oil pan, separate the oil pan held by the RTV sealant.

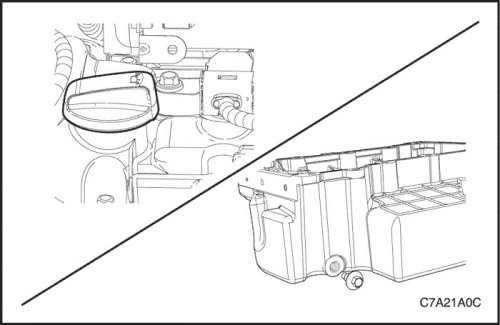

13. Remove the oil pan from the cylinder block.

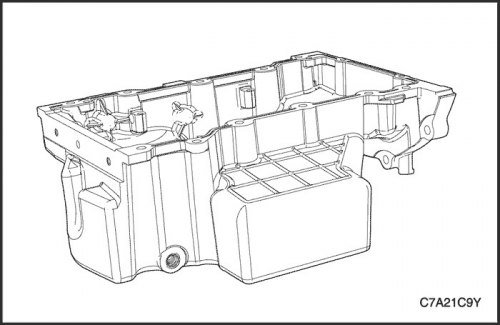

Disassembly

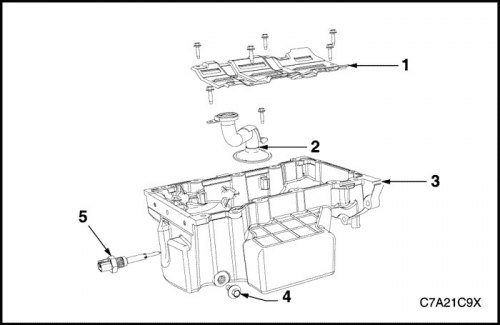

1. oil pan (3), drain plug (4) and bushing.

2. Oil level sensor (5).

3. Crankshaft oil slinger bolts and oil slinger (1).

4. Oil pump suction pipe bolts and suction pipe (2).

5. Gasket from the suction pipe of the oil pump; send the gasket to the waste.

Clear

1. Remove any remaining thread sealant, gasket material and sealant using a conventional wooden or plastic scraper.

2. Wash the oil pan and its components in solvent.

3. Remove all debris from bolt holes.

4. Dry the oil pan and its components with compressed air.

Inspection

1. Inspect the outside of the oil pan, checking for the following faults:

- Damaged drain plug or drain hole

- Damage to the mounting bosses for mounting the gearbox

- Damage to the threads of the oil level sensor

- Potholes or damage to the cover on the outside.

2. Dry the oil pan and its components with compressed air.

- Chips or damage to the sealing surfaces of the oil pan

- Damage to the crankshaft oil deflector

- Damage to bolt holes

- Damage to the mounting bosses of the oil suction tube

- Damage to the mounting bosses of the crankshaft oil deflector.

3. Inspect the oil pan damper for damage.

4. Repair or replace the oil pan and (or) its components, if required.

5. Check the following:

- A. Joint surface (1) suction pipe of the oil pump, which may have defects leading to leakage.

- B. Suction tube (2) oil pump, on which cracks, defects and (or) damage.

- C. Bracket (3) oil pump tube, which may be cracked or damaged.

- D. Strainer (4) oil pump, which may be clogged, clogged, torn and (or) damaged.

6. Repair or replace the oil pan and (or) its components, if required.

Assembly

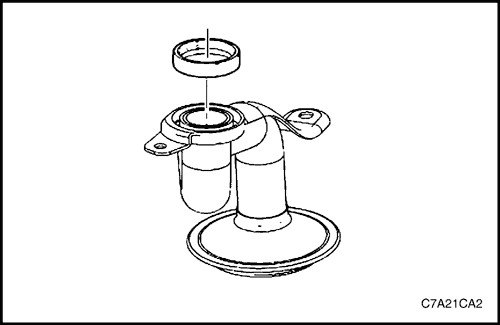

1. Install a new seal on the oil suction pipe.

2. Install the oil suction pipe and tighten the bolts.

- Chips or damage to the sealing surfaces of the oil pan

- Damage to the crankshaft oil deflector

- Damage to bolt holes

- Damage to the mounting bosses of the oil suction tube

- Damage to the mounting bosses of the crankshaft oil deflector.

Tighten

Tighten retaining bolts for oil suction pipe to 10 Nm (89 lb-in.).

3. Install the crankshaft oil deflector into the oil pan and tighten the fixing bolts.

Tighten

Tighten the bolts securing the crankshaft oil deflector to the oil pan to 10 Nm (89 lb-ft).

4. Install the oil level sensor in the oil pan.

Tighten

Tighten the oil level sensor to 20 Nm (15 lb-in.).

5. Install the oil pan drain plug.

Tighten

Tighten the oil pan drain plug to 25 Nm (18 lb-ft).

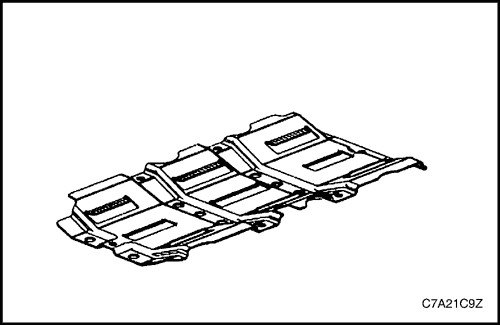

Installation procedure

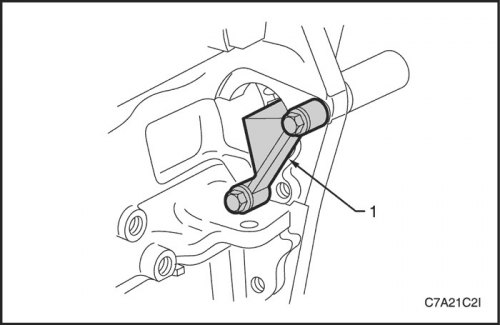

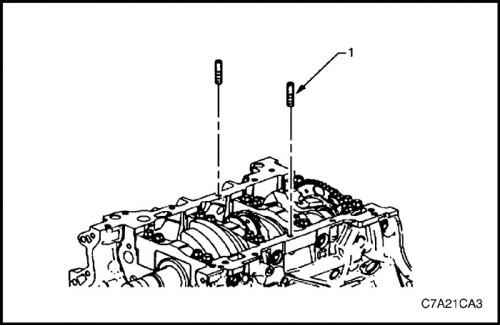

1. Install guide pins EN-46109 (1) into the bolt holes at the oil pan interface on both sides of the cylinder block.

Tighten

Tighten the intake manifold set screws and nuts to 22 Nm (16 lb-ft).

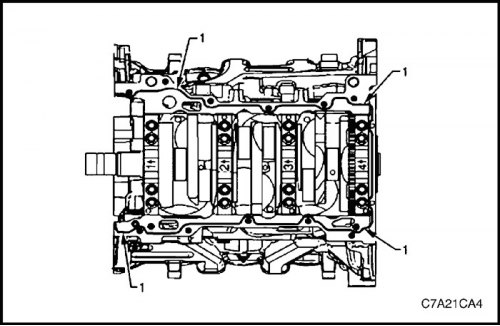

2. Apply a bead of RTV sealant (1) 3 mm wide at the junction of the cylinder block and the crankshaft rear oil seal housing with the oil pan.

3. Install the oil pan on the cylinder block.

4. Remove the EN-46109 guide pins from the cylinder block.

5. Loosely install the oil pan bolts.

6. Tighten the oil pan bolts in the sequence shown.

Tighten

Tighten the bolts securing the oil pan to the cylinder block to 23 Nm (17 lb-ft).

Tighten the bolts securing the oil pan to the crankshaft rear oil seal housing (12 - 13) torque 10 Nm (89 lb-in).

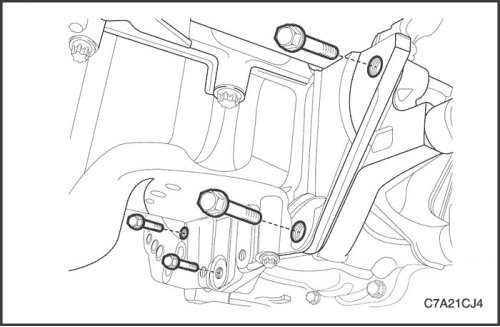

7. Remove the oil pan flange retaining screws to the transaxle assembly.

Tighten

Tighten the oil sump flange-to-transaxle bolts to 50 Nm (37 lb-ft).

8. Remove the transfer case bracket bolts. See Part 5D. "Transfer case".

9. Install the timing belt front cover. See this section.

10. Install the engine assembly. Follow the point in this section.

11. Install the oil pan drain plug.

Tighten

Tighten the oil pan drain plug to 25 Nm (18 lb-ft).

12. Install the front exhaust pipe. See Part 1G3, Engine exhaust system.

13. Pour engine oil into the oil pan.