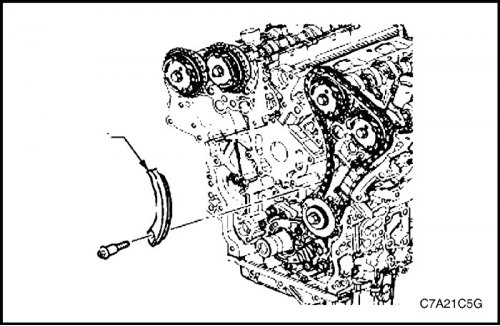

Attention! Setting the valve timing is required in all cases where the camshaft drive system has been affected and the required relationship between any chain and sprocket has been violated. Even if this applies to only one sprocket, repeated rotations of the crankshaft will not reproduce conditions in which it is possible to maintain the correct valve timing. To set the valve timing, if required, follow the bank 2 secondary camshaft timing chain installation instructions.

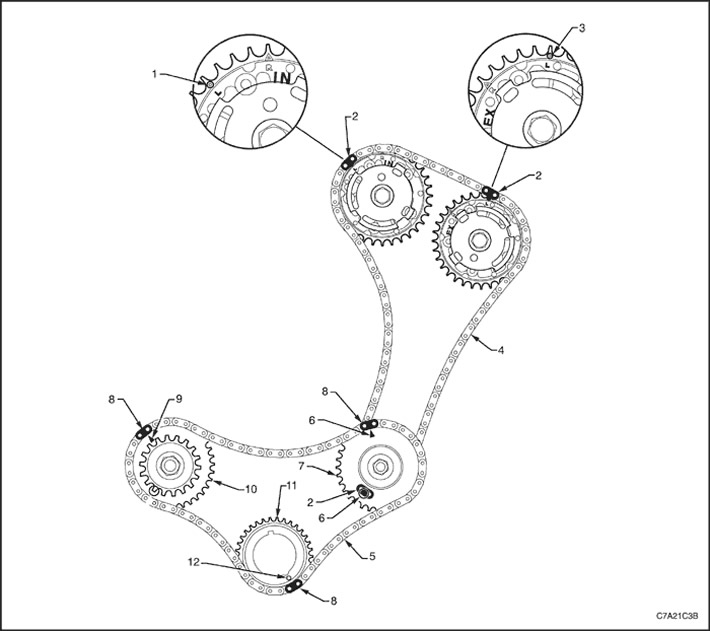

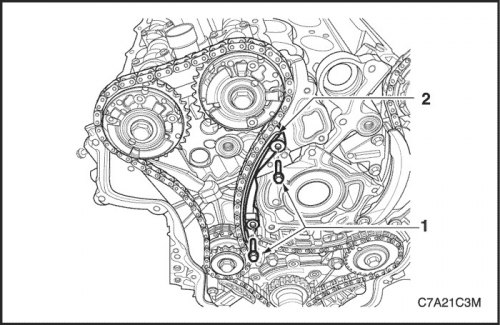

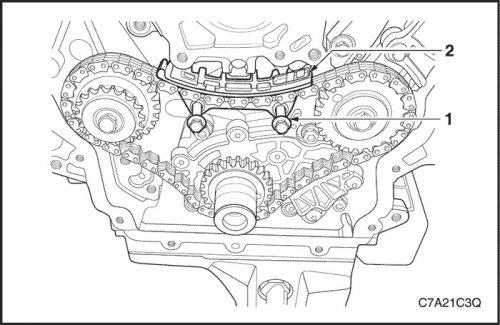

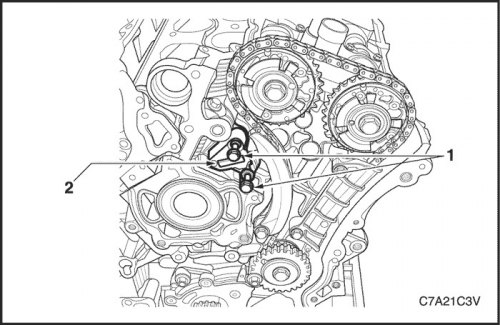

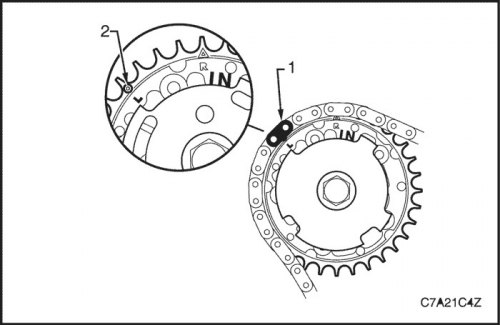

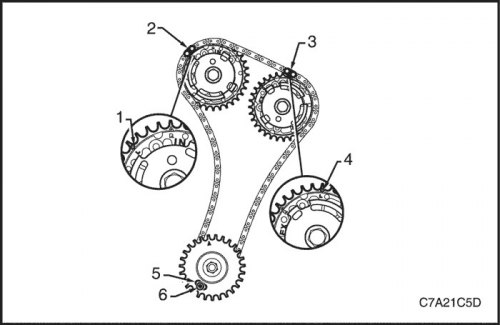

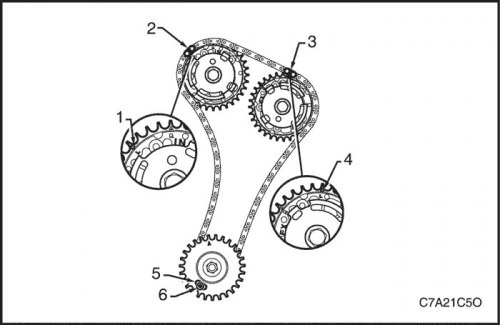

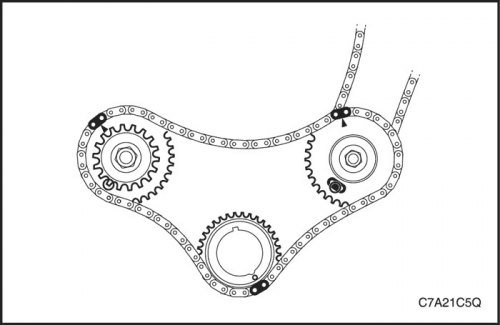

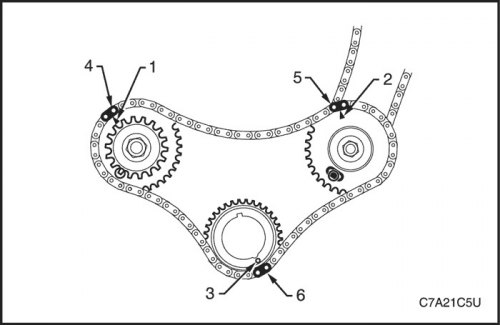

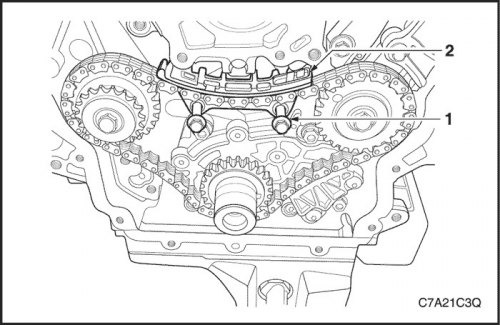

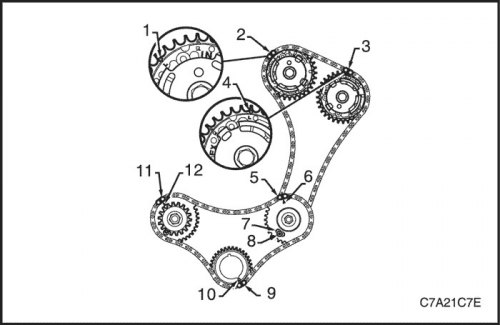

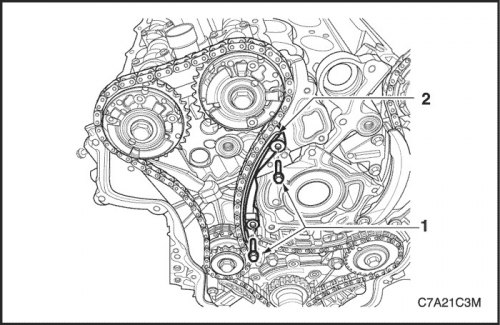

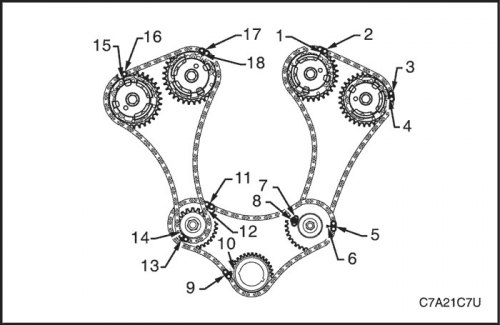

Installation of chains of primary drive and secondary drive of camshafts of a number of cylinders 2

1. Installation mark of the drive for regulating the valve timing of the intake camshaft, row 2

2. Secondary Camshaft Drive Chain Shiny Link Bank 2

3. Installation mark of the drive for regulating the valve timing of the exhaust camshaft, row 2

4. Secondary Camshaft Drive Circuit, Bank 2

5. Chain of primary drive of camshafts

6. Alignment mark of an asterisk of an asterisk of an intermediate shaft of a drive of camshafts, row 2

7. Camshaft intermediate shaft sprocket, row 2

8. Shiny link in the primary camshaft drive chain

9. Alignment mark of an asterisk of an asterisk of an intermediate shaft of a drive of camshafts, row 2

10. Camshaft intermediate shaft sprocket, row 1

11. crankshaft sprocket

12. Timing mark for crankshaft sprocket

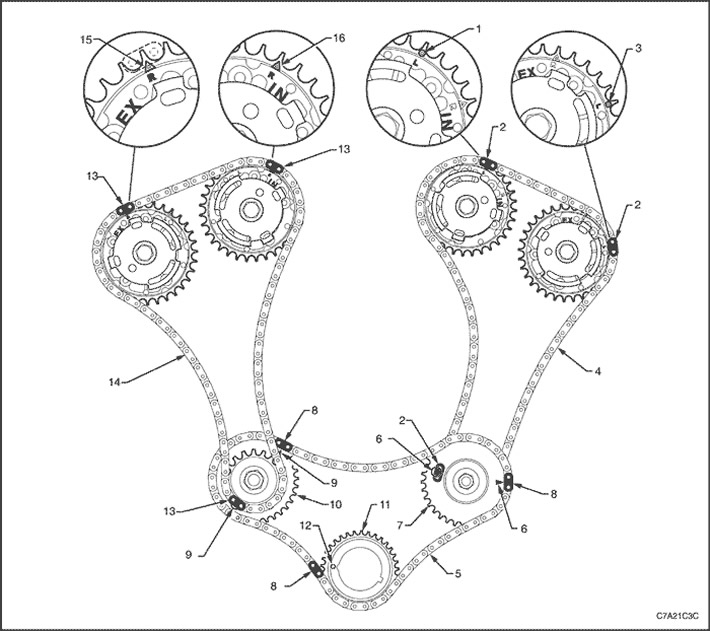

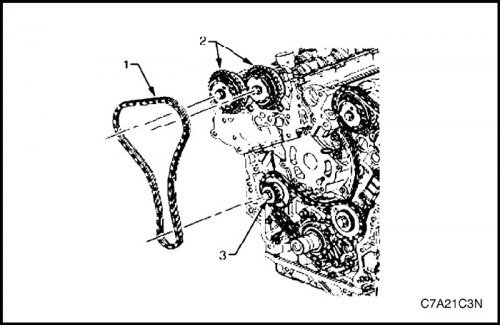

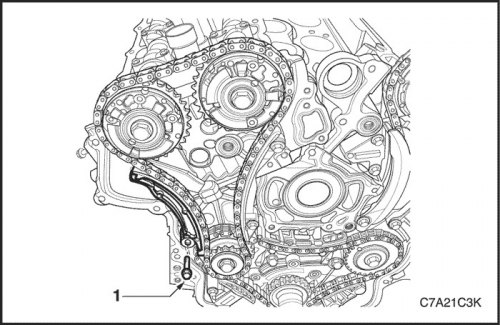

Installation of a chain of a secondary drive of camshafts of a number of cylinders 1

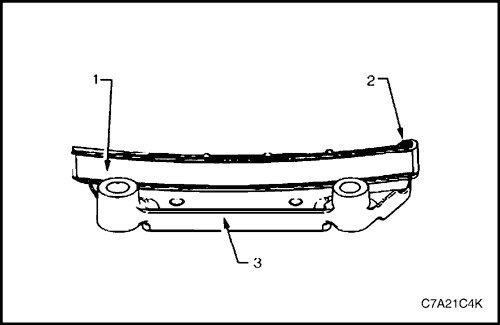

1. Installation mark of the drive for regulating the valve timing of the intake camshaft, row 2

2. Secondary Camshaft Drive Chain Shiny Link Bank 2

3. Installation mark of the drive for regulating the valve timing of the exhaust camshaft, row 2

4. Secondary Camshaft Drive Circuit, Bank 2

5. Chain of primary drive of camshafts

6. Alignment mark of an asterisk of an asterisk of an intermediate shaft of a drive of camshafts, row 2

7. Camshaft intermediate shaft primary drive sprocket, bank 2

8. Shiny link in the primary camshaft drive chain

9. Alignment mark of an asterisk of an asterisk of an intermediate shaft of a drive of camshafts, row 2

10. Camshaft intermediate shaft sprocket, row 1

11. crankshaft sprocket

12. Timing mark for crankshaft sprocket

13. Secondary Camshaft Drive Chain Shiny Link Bank 1

14. Intermediate chain of a drive of camshafts, number 1

15. Installation mark of the drive for regulating the valve timing of the exhaust camshaft, row 1

16. Installation mark of the drive for regulating the valve timing of the intake camshaft, row 1

Removal procedure

Bank 1 camshaft secondary drive circuit

Attention! After removing the upper intake manifold and spark plugs, plug all openings to prevent dirt and foreign matter from entering inside.

1. Remove the engine front cover assembly. See «Front cover assembly» in this section.

2. Remove the spark plugs to make it easier to turn the crankshaft or engine.

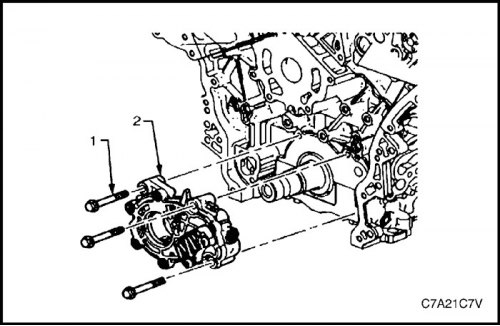

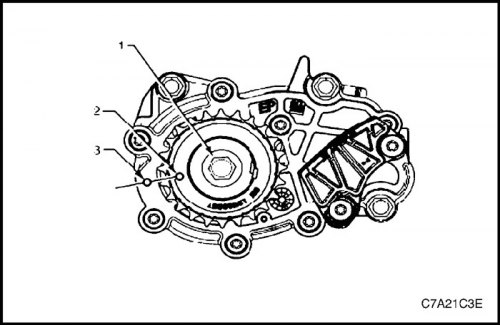

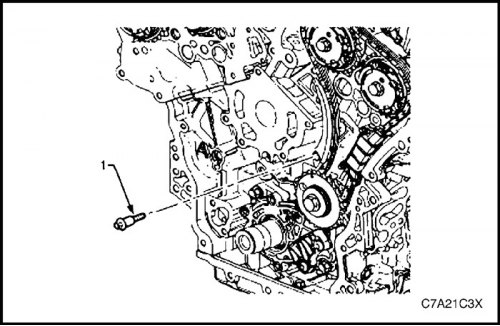

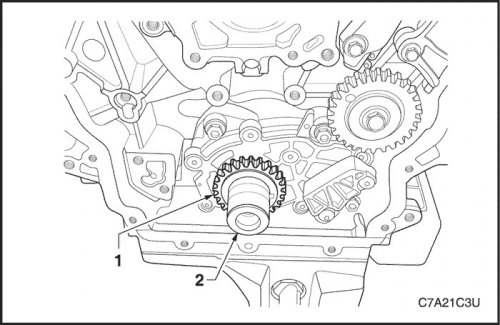

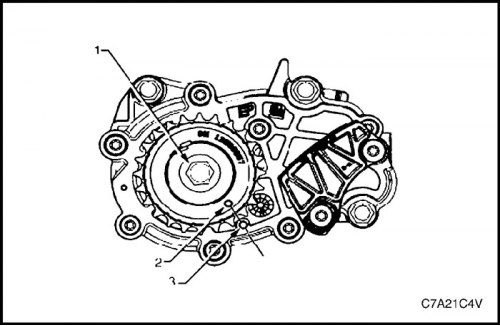

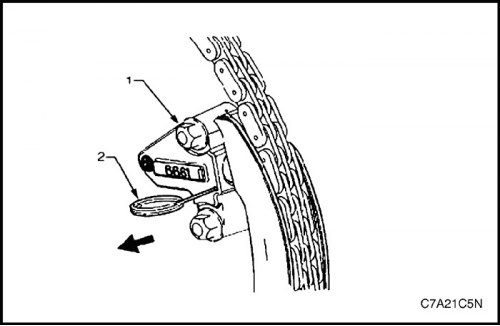

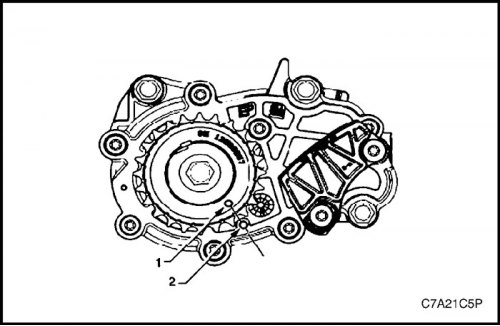

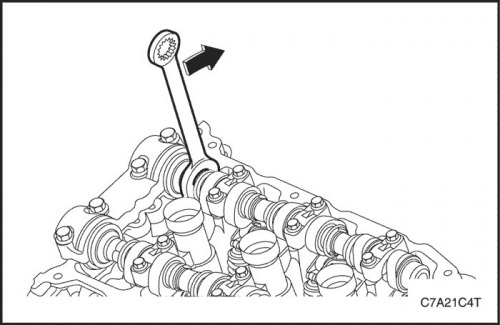

3. Install on crankshaft (2) fixture EN-46111 (1).

4. Using the EN-46111 fixture (1) turn the crankshaft clockwise to align the alignment mark (2) on the crankshaft sprocket with a mark (3) on the oil pump housing.

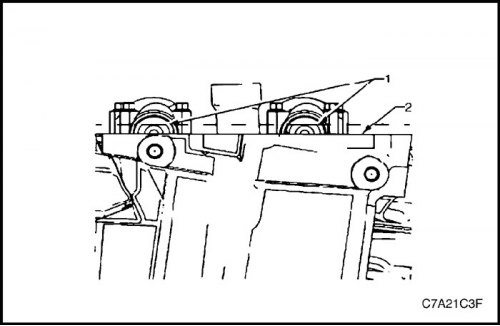

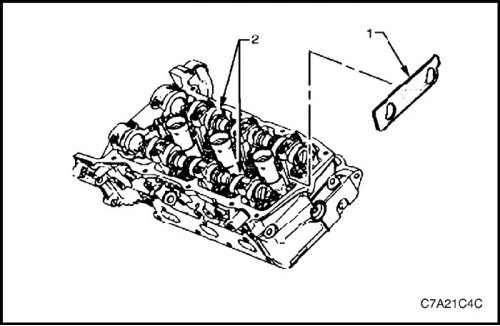

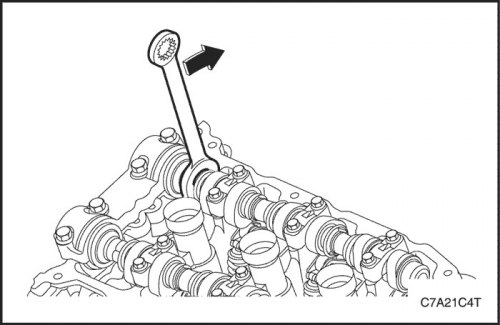

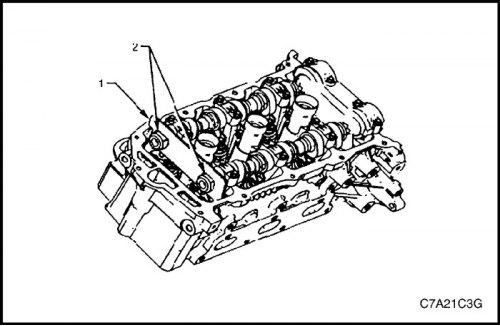

5. After aligning the marks, check if the flats are parallel (1) camshafts at the rear end of the bank 1 cylinder head interface (2) with cylinder head cover.

6. If the camshaft flats are not as shown, rotate the crankshaft 360°.

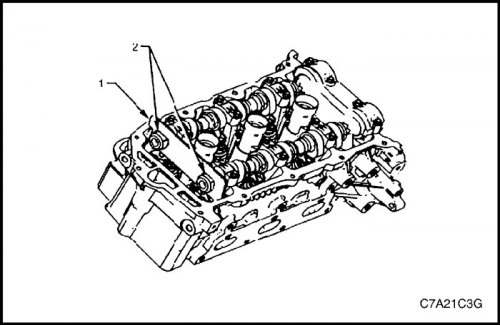

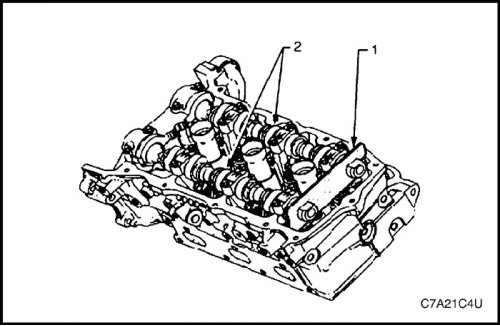

7. Install fixture EN 46105-1 (1) on the rear ends of the camshafts (2) cylinder bank 1.

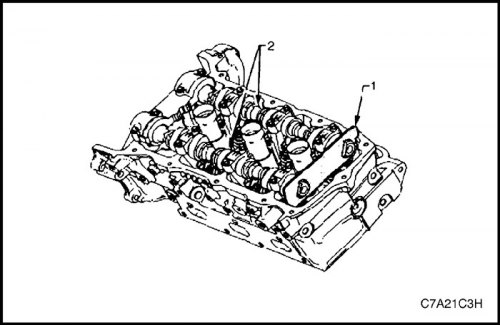

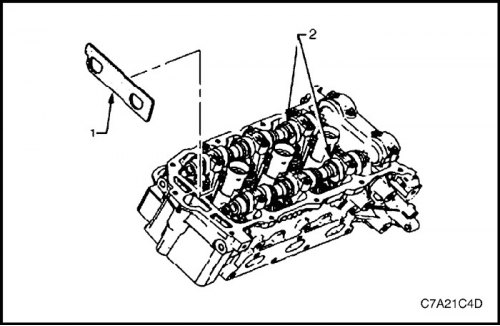

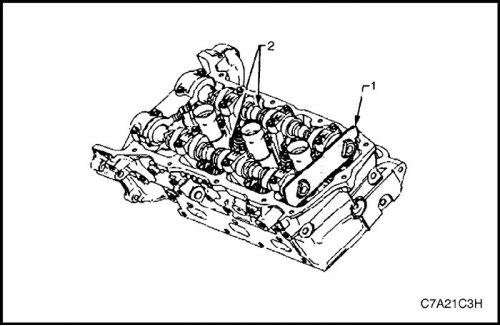

8. Install fixture EN 46105-2 (1) on the rear ends of the camshafts (2) row of cylinders 2.

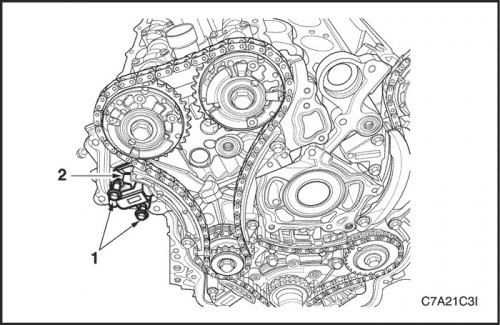

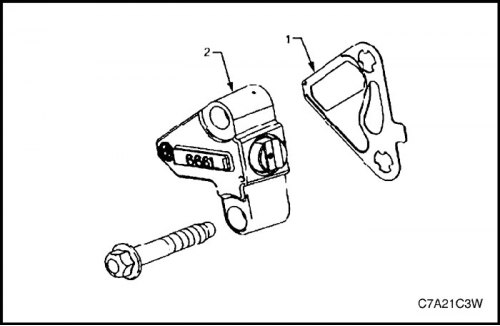

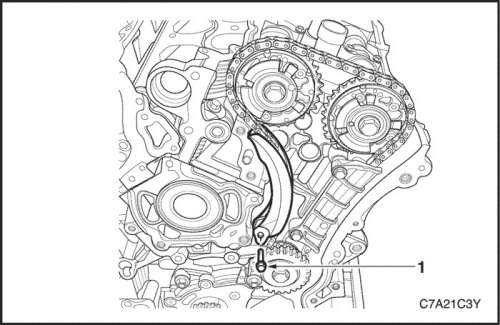

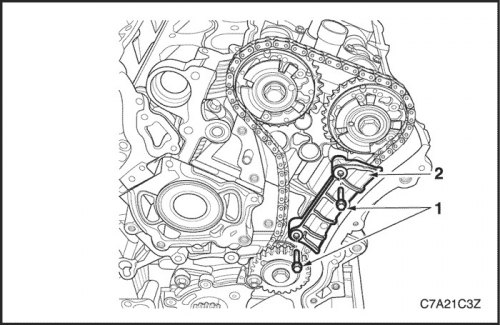

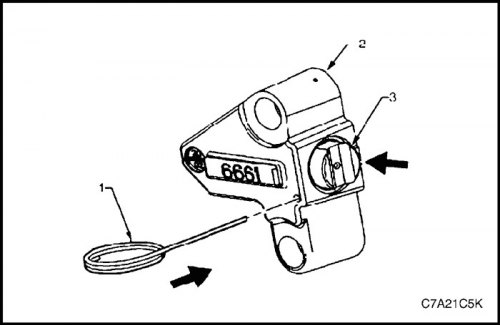

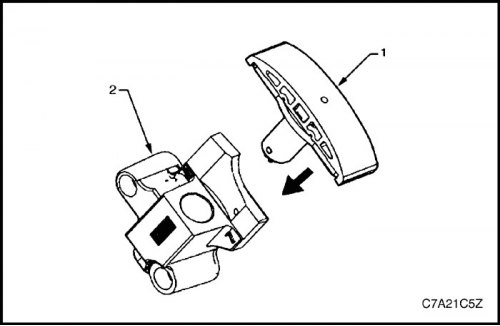

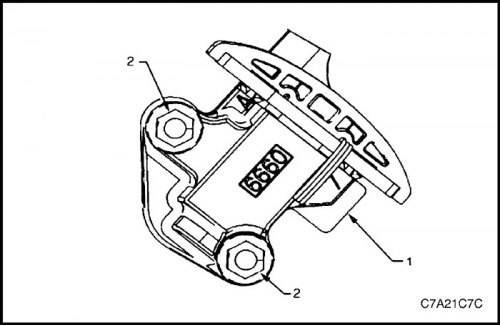

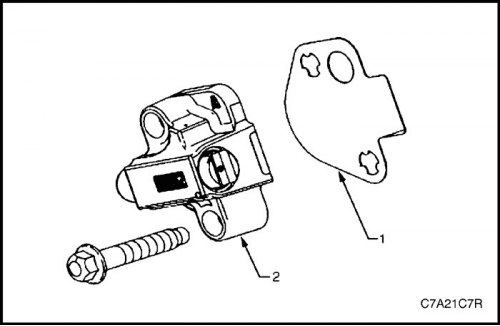

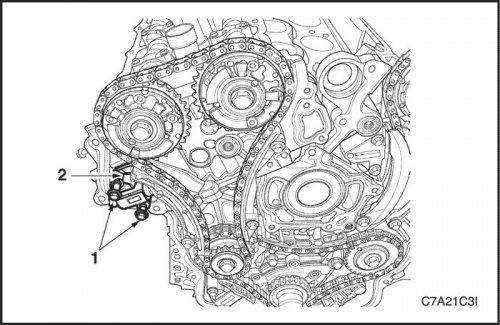

9. Remove bolts (1) chain tensioner for the secondary camshaft drive chain 1 and remove the tensioner (2).

Note: Care must be taken when removing tensioner bolts. The tensioner plunger may spring back and pop out when the tensioner is removed.

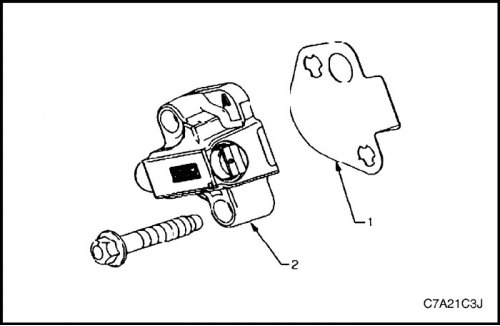

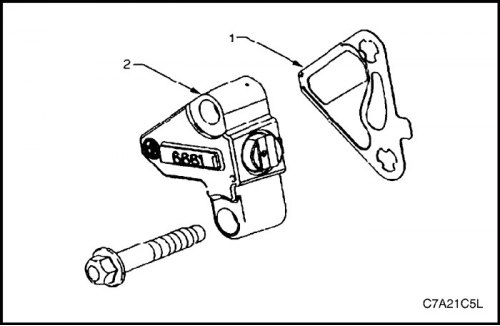

10. Remove gasket (1) from the tensioner (2) and send it to waste.

11. Inspect the tensioner mounting surface on the bank 1 cylinder head for burrs that could interfere with the new tensioner gasket seal.

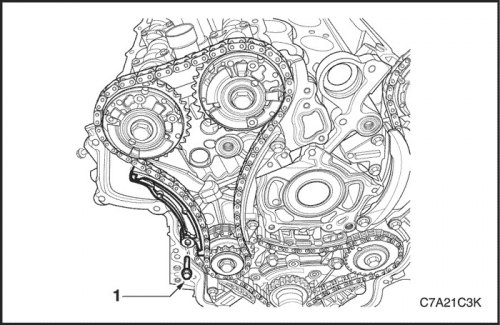

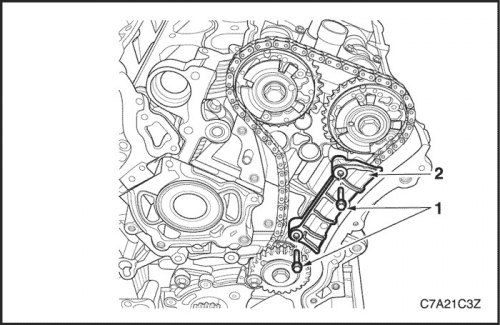

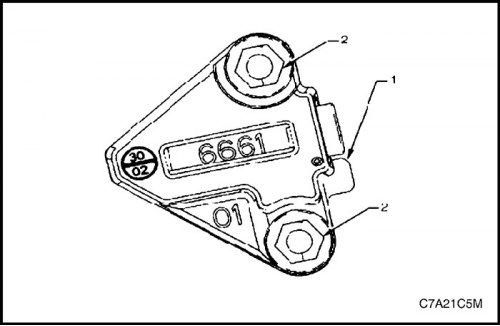

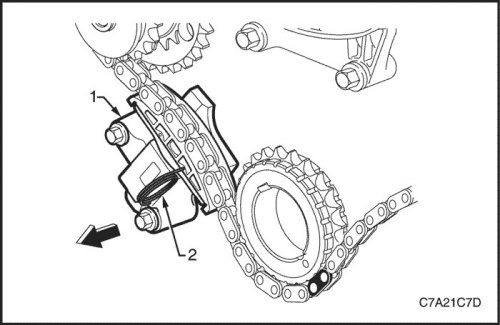

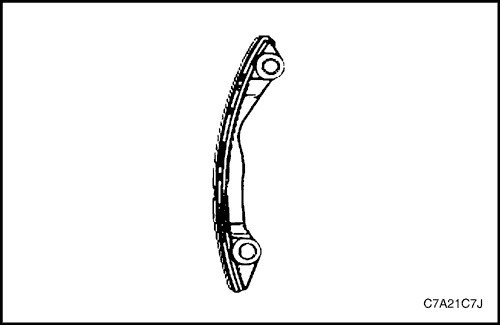

12. Remove bolt (1) chain shoe for secondary camshaft drive chain 1.

13. Remove shoe (1) chains of the secondary drive of camshafts of a number of cylinders 1.

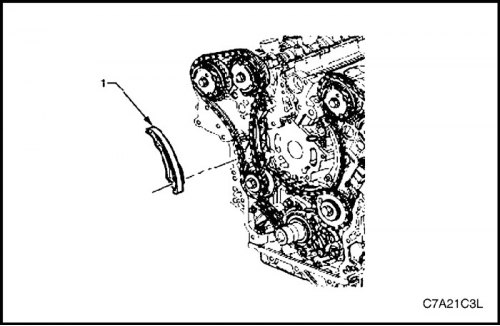

14. Remove two bolts (1) secondary camshaft drive chain guide for bank 1 and remove the chain guide (2).

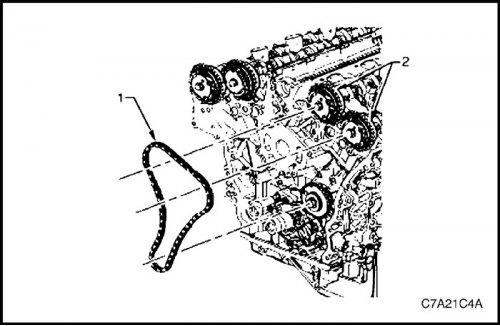

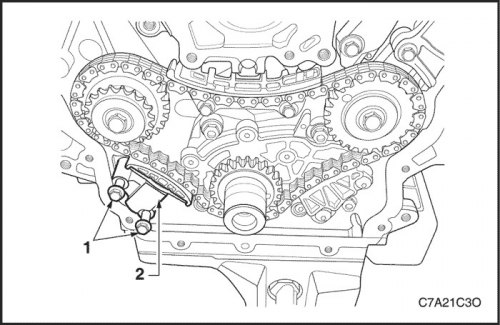

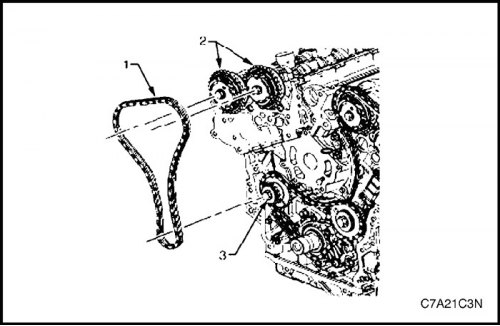

15. Remove the chain (1) secondary camshaft drive for cylinder bank 1 with drives (2) variable valve timing and sprocket (3) intermediate shaft of the camshaft drive.

Chain of primary drive of camshafts

1. Remove the bank 1 secondary camshaft drive chain. «Camshaft Drive Chain Components» in this section.

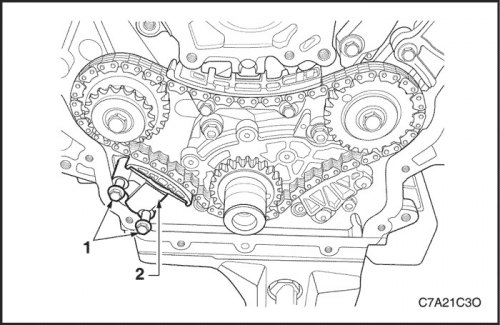

2. Remove two bolts (1) chain tensioner of the primary camshaft drive and remove the tensioner (2).

Note: Care must be taken when removing tensioner bolts. The tensioner plunger may spring back and pop out when the tensioner is removed.

3. Remove gasket (1) from the tensioner (2) and send it to waste.

4. Inspect the surface on the cylinder block where the primary camshaft timing chain tensioner will be installed, checking for nicks that could affect the seal of the new tensioner gasket.

5. Remove two bolts (1) the top guide chain of the primary camshaft drive and remove the guide (2).

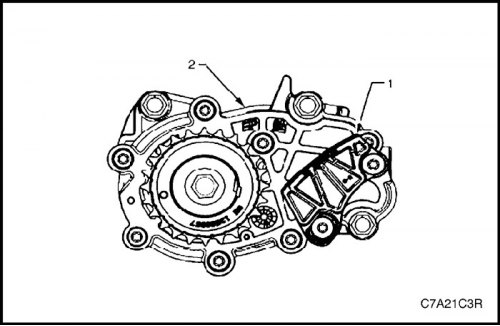

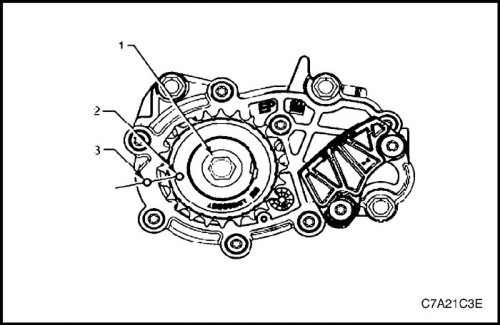

Note: Do not remove the bottom rail (1) camshaft primary drive circuits. The bottom rail is not intended for separate service. If it is necessary to replace the lower guide chain of the primary camshaft drive, then the oil pump should be replaced (2) assembled.

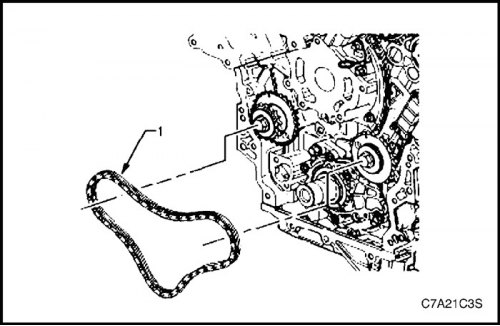

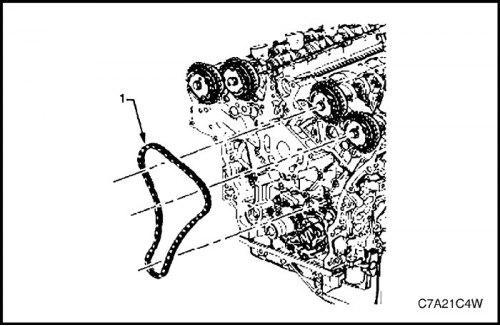

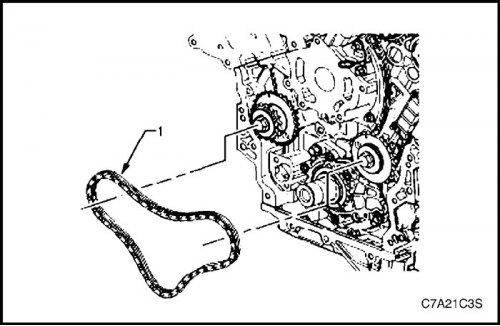

6. Remove the chain (1) primary drive camshafts.

Note: To facilitate removal, before removing the chain from the intermediate drive shaft sprockets, remove it from the crankshaft sprocket.

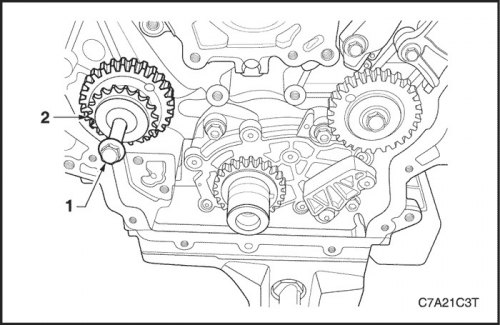

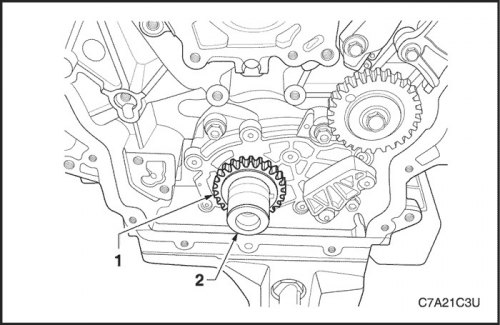

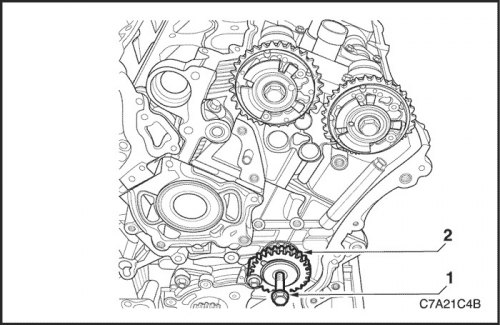

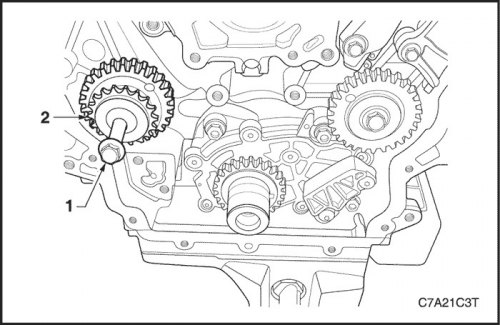

7. If necessary, remove the bolt (1) intermediate shaft sprocket for bank 1 camshaft drive, and then remove the sprocket (2).

8. If necessary, remove the asterisk (1) from the crankshaft (2).

Bank 2 camshaft secondary drive circuit

1. Remove the primary camshaft drive chain. See «Camshaft Drive Chain Components» in this section.

2. Remove two bolts (1) chain tensioner for bank 2 secondary camshaft drive chain and remove the tensioner (2).

Note: Care must be taken when removing tensioner bolts. The tensioner plunger may spring back and pop out when the tensioner is removed.

3. Remove gasket (1) from the tensioner (2) and send it to waste.

4. Inspect the tensioner mounting surface on the bank 2 cylinder head for nicks or other imperfections that could affect the new tensioner gasket seal.

5. Remove bolt (1) chain shoe for the secondary camshaft drive chain 2.

6. Remove shoe (1) chains of the secondary drive of camshafts of a number of cylinders 2.

7. Remove bolt (1) secondary camshaft drive chain guide for bank 2 and remove the guide (2).

8. Remove the chain (1) secondary drive camshafts for cylinder bank 2 with drives (2) control of the valve timing and from the sprocket of the intermediate shaft of the camshaft drive.

9. If necessary, remove the bolt (1) camshaft sprocket bank 2, and then remove the sprocket (2).

10. Remove fixture EN 46105-2 (1) from camshafts (2) row of cylinders 2.

11. Remove fixture EN 46105-1 (1) from camshafts (2) cylinder bank 1.

Clear, clean

1. Clean all components listed below with a suitable solvent:

- crankshaft sprocket,

- camshaft primary drive circuit,

- camshaft primary drive chain guide,

- camshaft primary drive chain tensioner,

- chains of the secondary drive of camshafts,

- shoes of chains of the secondary drive of camshafts,

- secondary camshaft drive chain guides,

- chain tensioners for the secondary camshaft drive and

- bolts.

2. Dry all components with compressed air.

Inspection

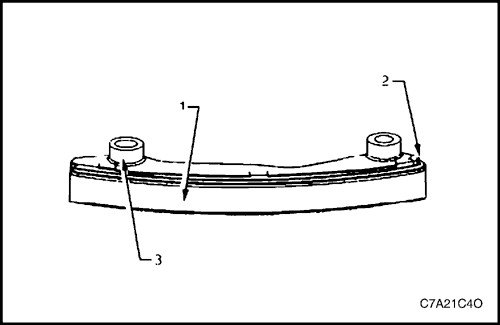

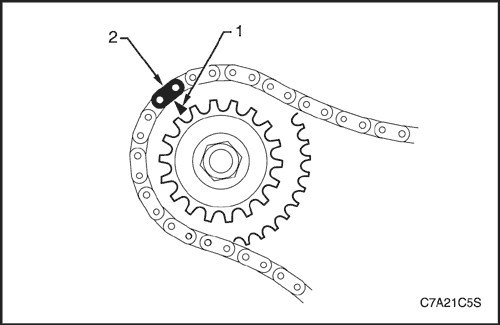

Camshaft drive chains

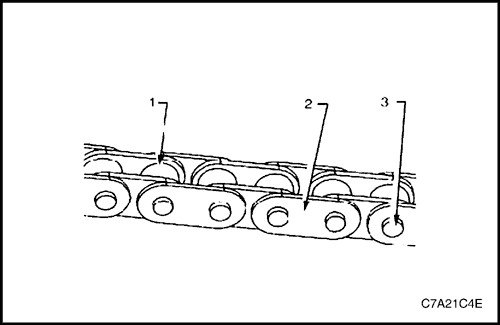

1. Inspect the primary and (or) secondary camshaft drive, checking for the following faults:

- jamming or wear of rollers (1),

- weakly bonded plates (2), And

- loose axles (3).

2. Replace damaged camshaft timing chain if required.

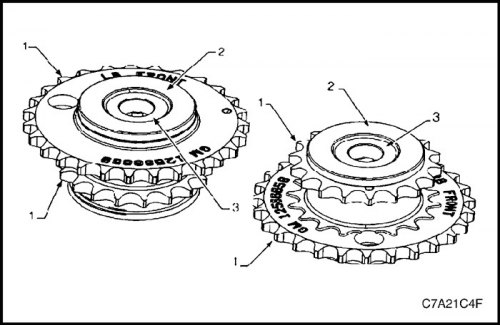

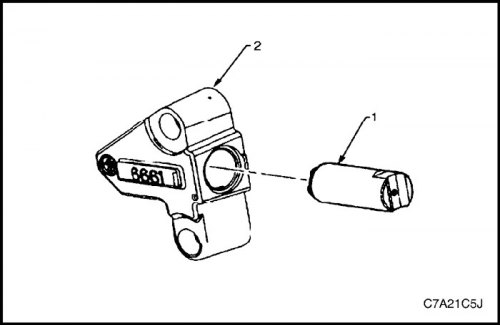

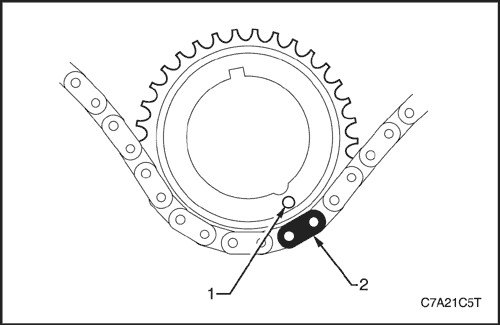

Sprockets of intermediate shafts of a drive of camshafts

1. Inspect the countershaft sprockets of the camshaft drive, checking for the following faults:

- Damaged primary or secondary drive sprocket (1).

- Bearing damage (2) hubs. Check if the bearing rotates freely. If swaying, noise or uneven rotation occur during rotation of the bearing, then the intermediate sprocket should be replaced.

- Damage to the seat / sealing surface for the bolt head (3).

- Damage to the sealing surface of the contact between the bearing hub and the cylinder block.

- Inspect the drive units for regulating the valve timing. See «Camshaft control actuator assembly» in this section.

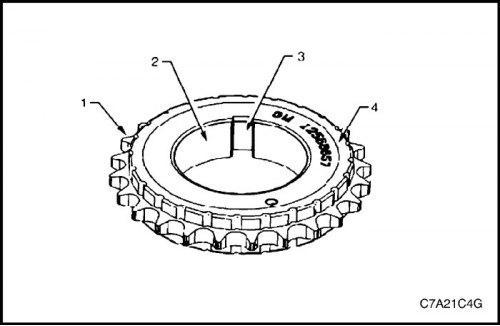

crankshaft sprockets

1. Inspect the crankshaft sprocket for the following faults:

- sprocket damage (1),

- hole damage (2),

- keyway damage (3),

- damage to the support surface material (4).

2. Replace damaged sprocket if necessary.

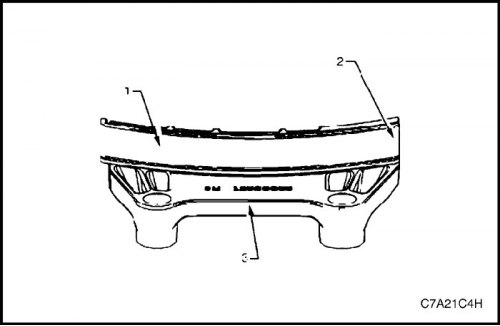

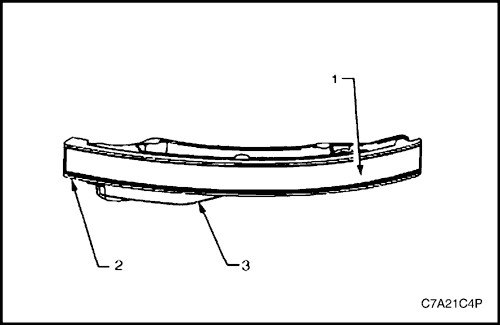

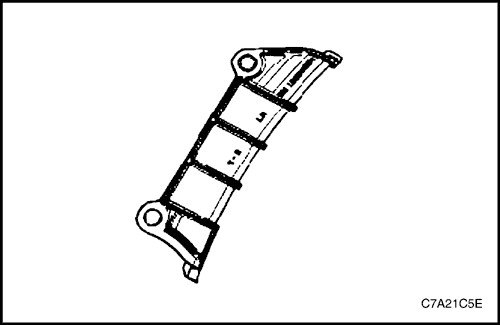

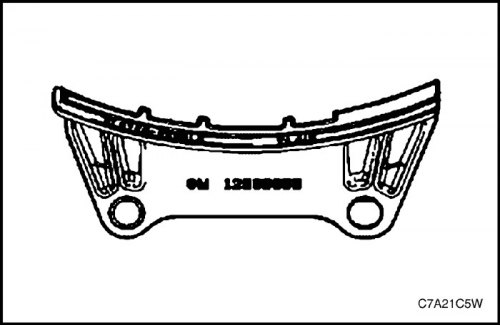

Upper Camshaft Primary Drive Chain Guide

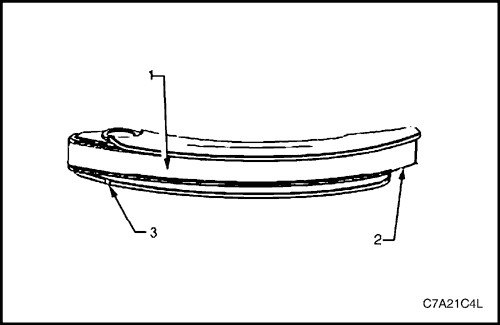

1. Inspect the upper camshaft drive chain guide for any of the following:

- guide surface wear (1),

- crack or break in guide surface (2),

- crack or damage to the base of the guide (3).

2. Replace damaged guide if necessary.

Primary Camshaft Drive Chain Lower Guide

1. Inspect the upper camshaft drive chain guide for any of the following:

- guide surface wear (1),

- crack or break in guide surface (2),

- crack or damage to the base of the guide (3).

Note: The lower camshaft drive chain guide is not serviced separately and is an integral part of the oil pump assembly.

2. Replacing the lower chain guide of the primary camshaft drive is done by replacing the oil pump. See «Oil pump assembly» in this section.

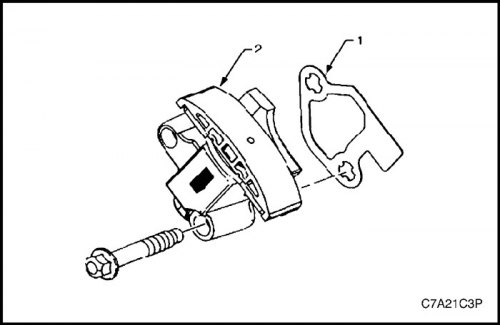

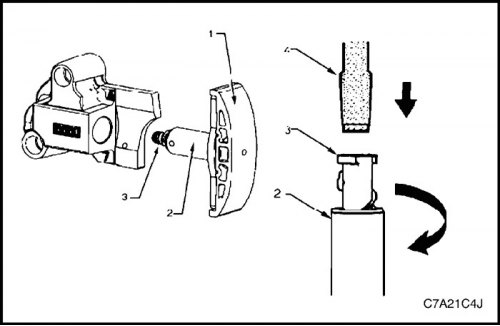

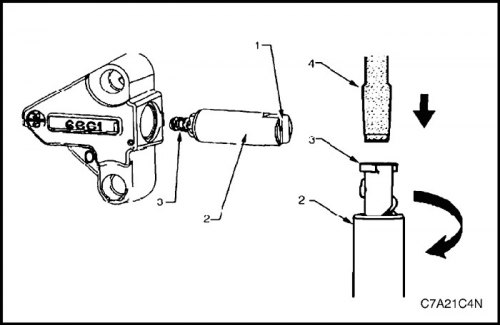

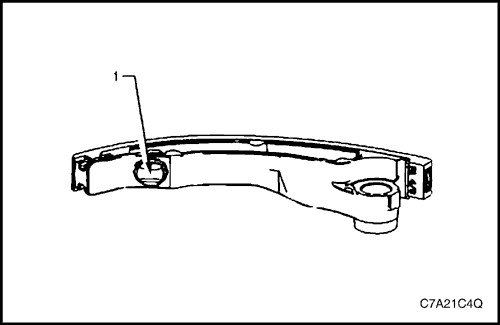

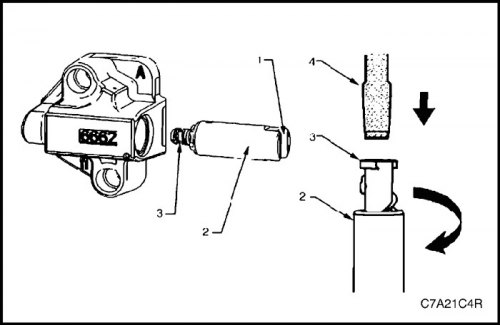

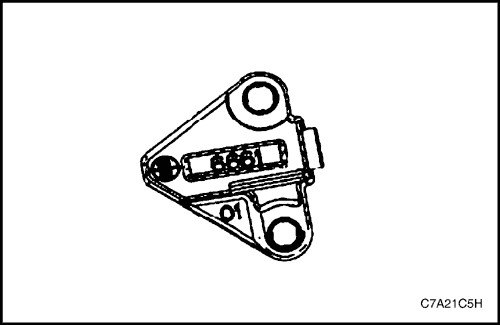

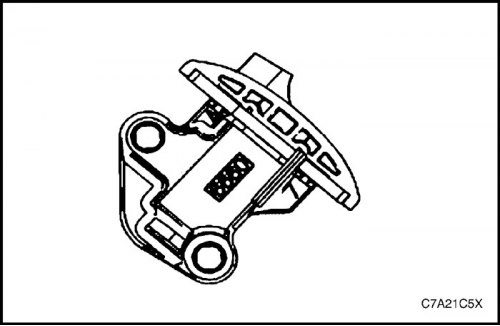

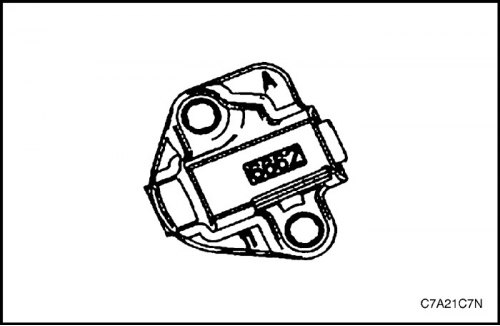

Timing chain tensioner

1. Inspect the primary camshaft drive chain tensioner for wear on the shoe surface (1).

2. Inspect the tensioner, checking for blocking or seizing of the shaft (2) tensioner. Install plunger (3) to its original position and make sure that the tensioner shaft slides in and out freely in the tensioner housing.

Note: To reset the tensioner, use a flat-tip screwdriver of the correct size (4), turning the plunger clockwise, insert it into the tensioner shaft.

3. Replace damaged tensioner if necessary.

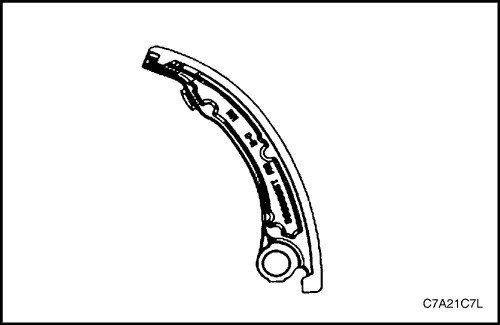

Secondary camshaft drive chain guide, bank 2

1. Inspect the bank 2 secondary camshaft drive chain guide for the following:

- guide surface wear (1),

- crack or break in guide surface (2),

- crack or damage to the base of the guide (3).

2. Replace damaged guide if necessary. Install plunger (3) to its original position and make sure that the tensioner shaft slides in and out freely in the tensioner housing.

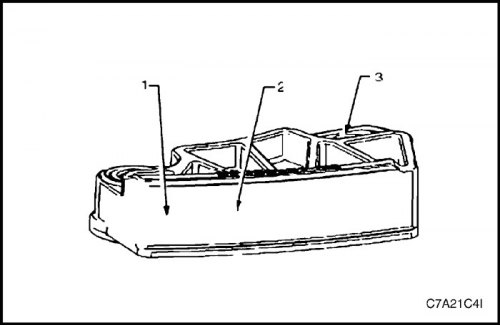

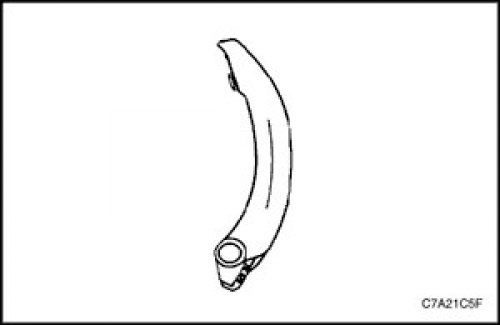

Shoe of a chain of a secondary drive of camshafts of a number of cylinders 2

1. Inspect the bank 2 secondary camshaft drive chain shoe from the front for any of the following:

- shoe surface wear (1),

- crack or break in the surface of the shoe (2),

- cracked or damaged shoe (3).

2. Inspect the rear of the shoe for damage or wear and for a missing pad (1) tensioner.

3. Replace damaged shoe if necessary.

Secondary timing chain tensioner bank 2

1. Inspect the bank 2 secondary camshaft timing chain tensioner for damage to the contact surface of the plunger and shoe (1).

2. Inspect the tensioner, checking for blocking or seizing of the shaft (2) tensioner. Install plunger (3) to its original position and make sure that the tensioner shaft slides in and out freely in the tensioner housing.

Note: To reset the tensioner, use a flat-tip screwdriver of the correct size (4), turning the plunger clockwise, insert it into the tensioner shaft.

3. Replace damaged tensioner if necessary.

Secondary camshaft drive chain guide, bank 1

1. Inspect the bank 1 secondary camshaft drive chain guide for the following:

- guide surface wear (1),

- crack or break in guide surface (2),

- crack or damage to the base of the guide (3).

2. Replace damaged guide if necessary.

Shoe of a chain of a secondary drive of camshafts of a number of cylinders 1

1. Inspect the shoe from the front of the secondary camshaft drive chain 1, checking for the following faults:

- shoe surface wear (1),

- crack or break in the surface of the shoe (2),

- cracked or damaged shoe (3).

2. Inspect the rear of the shoe for damage or wear and for a missing pad (1) tensioner.

3. Replace damaged shoe if necessary.

Secondary timing chain tensioner bank 1

1. Inspect the bank 1 secondary camshaft timing chain tensioner for damage to the contact surface of the plunger and shoe (1).

Note: To reset the tensioner, use a flat-tip screwdriver of the correct size (4), turning the plunger clockwise, insert it into the tensioner shaft.

2. Inspect the tensioner, checking for blocking or seizing of the shaft (2) tensioner. Install plunger (3) to its original position and make sure that the tensioner shaft slides in and out freely in the tensioner housing.

3. Replace damaged tensioner if necessary.

Installation procedure

Bank 2 camshaft drive components

1. Set asterisk (1) crankshaft to shaft (2), aligning the keyway with the key on the shaft.

2. Move the sprocket along the crankshaft until it contacts the shoulder on the shaft.

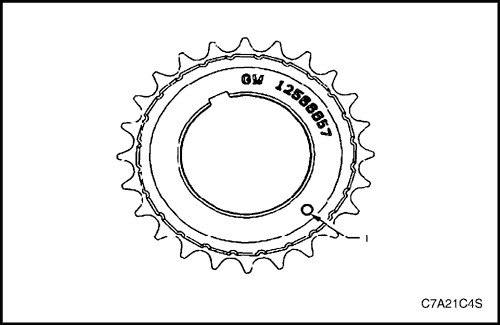

Note: Position the crankshaft sprocket so that the alignment mark is visible (1).

Attention! To mount the tool EN 46105 on the camshafts, turn the shafts counterclockwise. In this case, it is not necessary to rotate the shafts more than 45 degrees.

3. Install fixture EN 46105-1 (1) on the rear ends of the camshafts (2) cylinder bank 2, and install tool EN 46105-2 on the rear ends of the cylinder bank 1 camshafts.

Attention! Before installing the camshaft drive chains, it is necessary to block all the shafts in their places.

4. Make sure the EN 46105 fixture is fully seated on the camshafts.

5. Using the EN-46111 fixture (1) turn the crankshaft clockwise to align the alignment mark (2) on the crankshaft sprocket with a mark (3) on the oil pump housing.

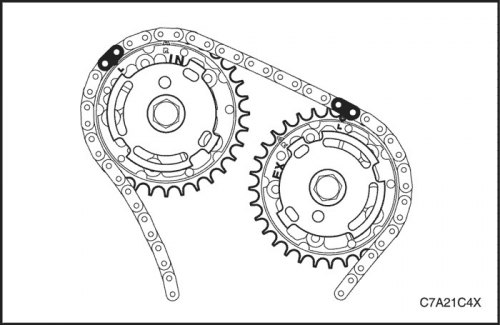

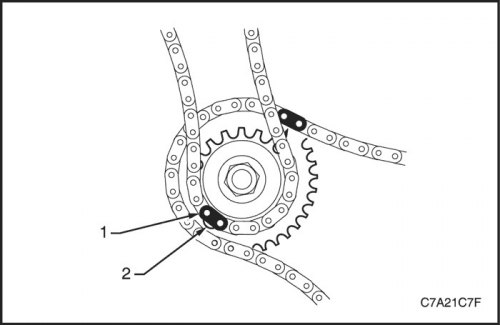

6. Install chain (1) secondary camshaft drive bank 2, placing the chain as follows:

A. Put a chain on both sprockets of the drive for adjusting the valve timing of the camshafts of bank 2.

B. Locate two shiny chain links above each of the camshaft timing drive sprockets.

Attention! When adjusting the position of the chain on the bank 2 camshaft timing actuator sprockets, use the timing marks in the form of circles, NOT in the form of triangles.

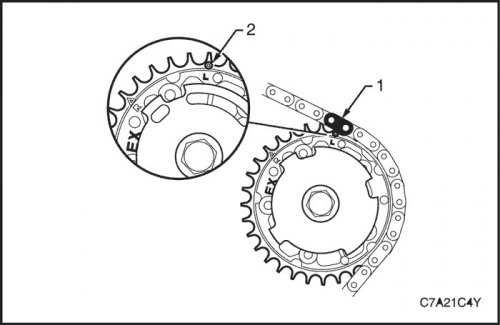

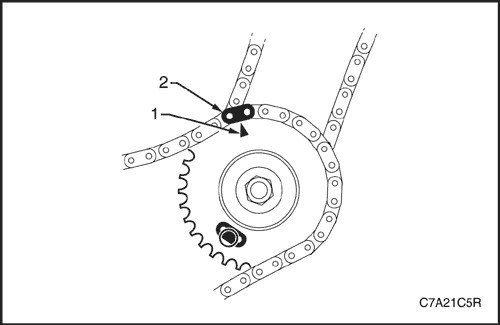

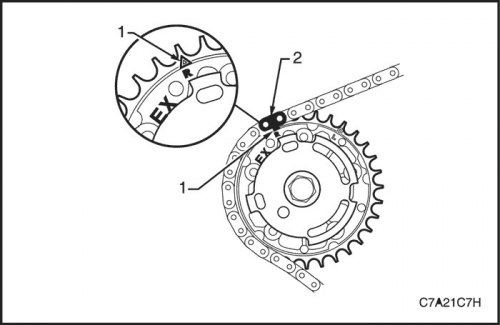

C. Match the shiny link (1) camshaft drive chains with a round alignment mark (2) on the camshaft sprocket of the exhaust camshaft, bank 2.

D. Match the shiny link (1) camshaft drive chains with a round alignment mark (2) on the intake camshaft camshaft control sprocket.

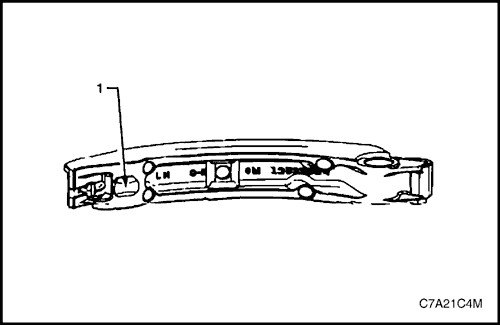

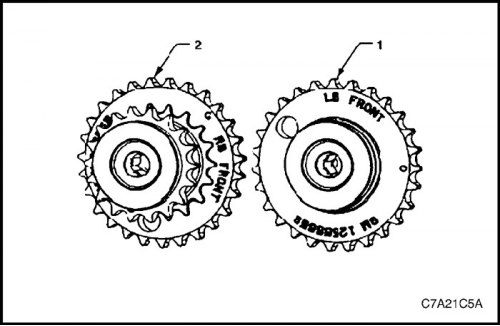

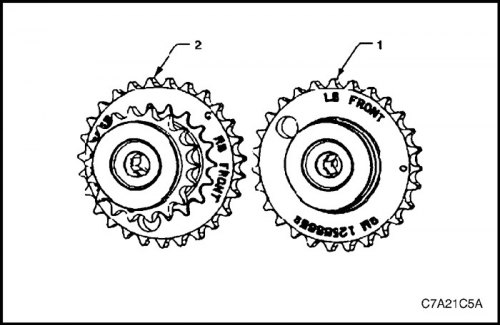

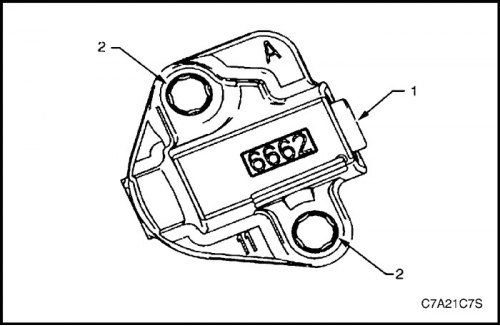

Attention! Star (1) the intermediate shaft of the camshaft drive for cylinder bank 2 is marked with the letters LB and "FRONT", and the asterisk (2) the intermediate shaft of the camshaft drive for cylinder bank 1 is marked with the letters RB and "FRONT". It is necessary not to confuse the stars and arrange them during installation so that the word "FRONT" was turned forward.

7. Make sure that the countershaft sprocket of bank 2 camshaft drive is correctly selected and oriented.

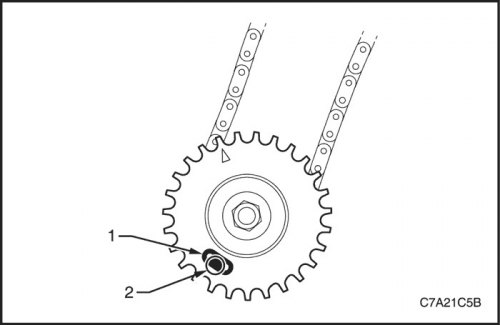

8. Position the bank 2 secondary camshaft drive chain around the left inner countershaft sprocket, aligning the shiny link (1) chains with a hole (2) in the outer star.

9. Install the intermediate shaft sprocket for bank 2 camshafts to the cylinder block.

Tighten

Tighten the intermediate shaft sprocket bolt to 66 Nm (49 lb-ft).

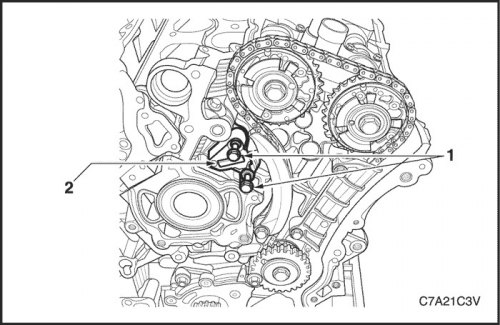

10. Check alignment of alignment marks (from 1st to 6th) bank 2 camshaft secondary drive circuits

Attention! The chain guide for the bank 2 secondary camshaft drive is marked with the letters LH. When installing the shoe on the bank 2 side, use the correct shoe and make sure that the letters LH face the front of the vehicle when installing.

11. Ensure correct selection and orientation of bank 2 secondary camshaft drive chain guide.

12. Install guide (1) chains of the secondary drive of camshafts of a number of cylinders 2.

Tighten

Tighten the secondary drive chain guide bolt to 23 Nm (17 lb-ft).

Attention! Shoe (2) the secondary camshaft drive circuit for cylinder bank 2 is marked with the letters LH on the reverse side. When installing the shoe on the bank 2 side, the correct shoe must be used.

13. Check correct selection and orientation of shoe for bank 2 secondary camshaft drive chain.

14. Install shoe (1) chains of the secondary drive of camshafts of a number of cylinders 2.

Note: Before tightening the mounting bolt, make sure that the secondary drive chain shoe does not come into contact with the bank 2 secondary chain tensioner mounting pad.

Tighten

Tighten the secondary camshaft drive chain shoe mounting bolt for cylinder bank 2 to 23 Nm (17 lb-ft).

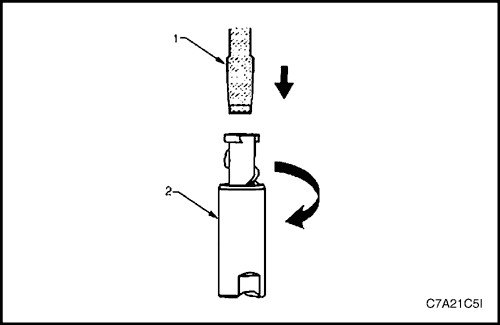

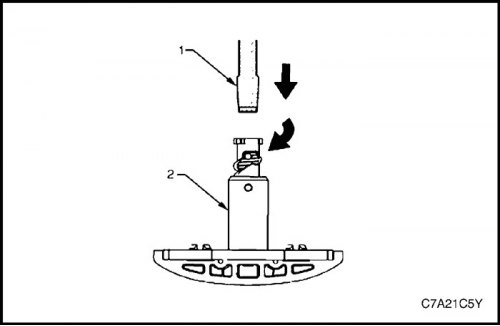

15. Check correct selection and orientation of bank 2 secondary camshaft timing chain tensioner.

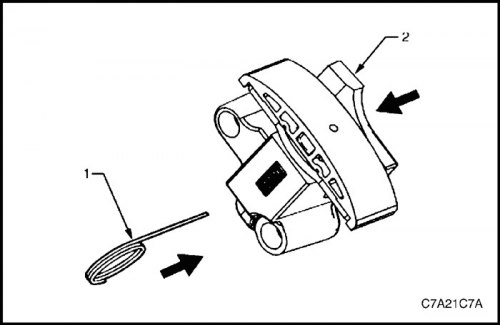

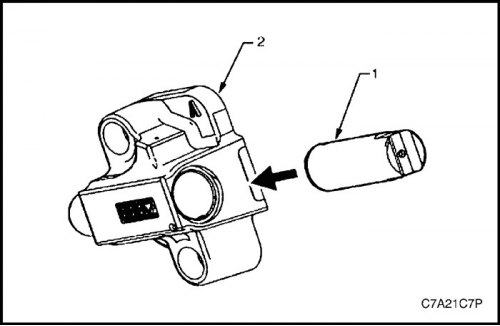

16. Reset the bank 2 secondary camshaft timing chain tensioner.

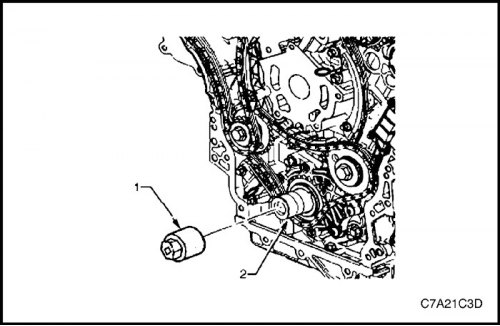

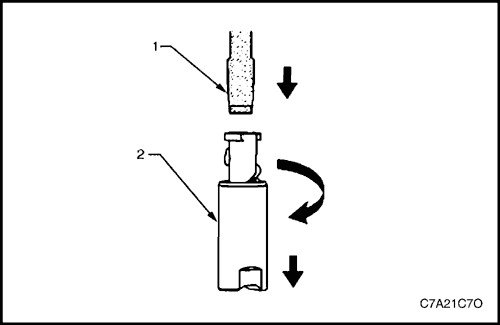

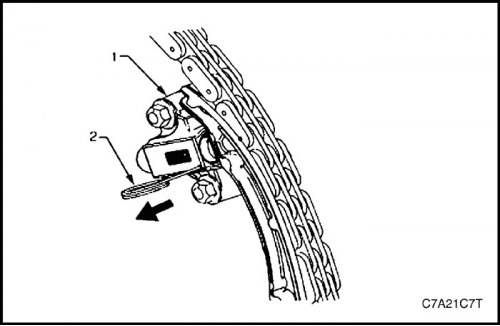

Note: To reset the tensioner, use a flat-tip screwdriver of the correct size (1), turning the plunger clockwise, insert it into the tensioner shaft (2).

17. install shaft (1) tensioner in the body (2) chain tensioner for the secondary camshaft drive of cylinder bank 2.

Attention! If fixture EN 46112 (1) not inserted into tensioner housing (2), then the shaft (3) tensioner will remain in the locked position and the camshaft timing chain will not be tensioned, resulting in engine damage.

18. Press the tensioner shaft into the housing and lock the bank 2 secondary drive chain tensioner by inserting tool EN 46112 into its hole in the side wall of the tensioner housing.

19. Slowly release the bank 2 secondary camshaft timing chain tensioner shaft. The tensioner must remain in its original position.

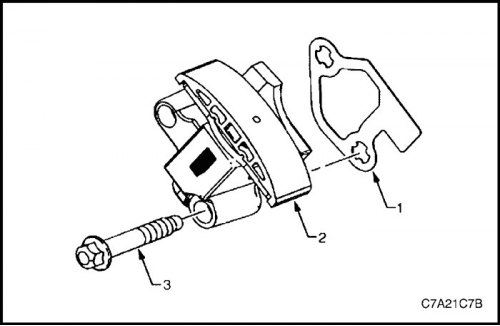

20. Install on tensioner (2) camshaft secondary drive chain 2 new gasket (1).

21. Install the bank 2 secondary camshaft timing chain tensioner bolts through the holes in the tensioner and gasket.

22. Verify that the bank 2 cylinder head mounting surface for the secondary chain tensioner is free of nicks or other imperfections that could affect the seal of the new tensioner gasket.

23. Install the tensioner (2) chains for the secondary camshaft drive of cylinder bank 2 and install the bolts (1) attachment to the cylinder head.

24. Check the correct position of the tongue (1) gaskets for the chain tensioner of the secondary camshaft drive of cylinder bank 2.

25. Tighten the bolts (2) chain tensioner for the secondary camshaft drive of cylinder bank 2.

Tighten

Tighten the secondary camshaft timing chain tensioner mounting bolts for cylinder bank 2 to 23 Nm (17 lb-ft).

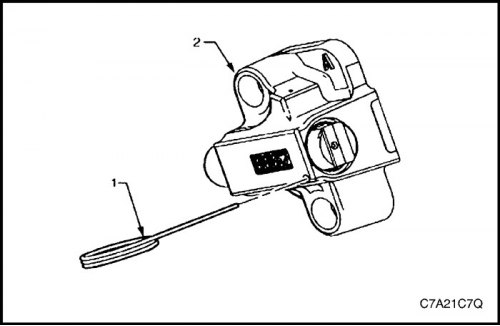

26. Unlock tensioner (1), by pulling out the tool EN 46112 (2) and free the tensioner shaft.

27. Check alignment of alignment marks (from 1st to 6th) bank 2 camshaft secondary drive circuits

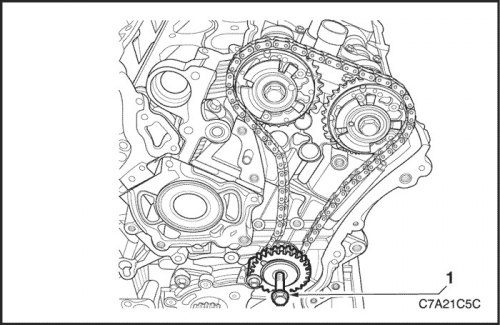

Camshaft Primary Drive Circuit Components

1. Install bank 2 secondary camshaft drive components, if previously removed. See «Camshaft Drive Chain Components» in this section.

Attention! Star (2) the intermediate shaft of the camshaft drive for cylinder bank 1 is marked with the letters RB and "FRONT", and the asterisk (1) the intermediate shaft of the camshaft drive for cylinder bank 2 is marked with the letters RB and "FRONT". It is necessary not to confuse the stars and arrange them during installation so that the word "FRONT" was turned forward.

2. Ensure correct selection and orientation of intermediate shaft sprocket for camshaft drive bank 1.

3. Set asterisk (2) Intermediate shaft for camshaft drive of cylinder bank 1.

Tighten

Tighten the camshaft intermediate shaft sprocket bolt for cylinder bank 1 to 65 Nm (48 lb-ft).

4. Make sure the setting mark (1) crankshaft sprocket aligned with mark (2) on the oil pump housing.

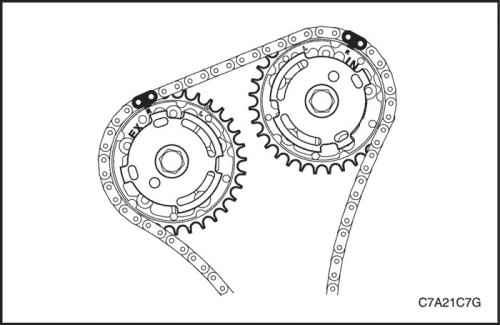

5. Install chain (1) primary drive camshafts.

6. Place the primary camshaft drive chain over the large sprockets on each of the countershafts and over the crankshaft sprocket, making sure the shiny chain links are in the following position:

A. Installation mark (1) intermediate shaft sprocket for bank 2 camshafts aligned with shiny link (2) camshaft primary drive circuits.

B. Installation mark (1) intermediate shaft sprocket for bank 1 camshafts aligned with shiny link (2) camshaft primary drive circuits.

C. Installation mark (1) crankshaft sprocket aligned with shiny link (2) drive chain.

7. Make sure that all reference marks (1, 2 and 3) combined with matching shiny links (4, 5 and 6) camshaft drive chains.

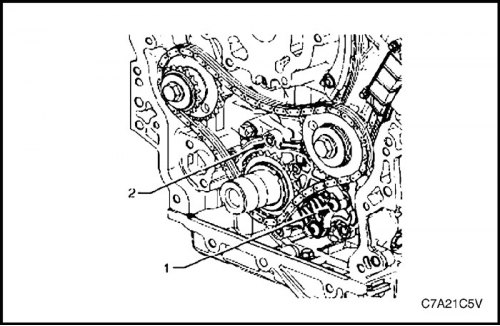

Note: Do not remove the bottom rail (1) camshaft primary drive circuits. The bottom rail is not intended for separate service. If it is necessary to replace the lower guide chain of the primary camshaft drive, then the oil pump should be replaced (2) assembled.

8. Check the correct selection and orientation of the primary camshaft drive chain guide.

9. Install top guide (1) camshaft primary drive circuits.

10. Install bolts (2) the upper guide chain of the primary drive of the camshafts.

Tighten

Tighten the primary drive chain guide bolts to 23 Nm (17 lb-ft).

11. Install the camshaft timing chain tensioner.

12. Reinstall the primary camshaft drive chain tensioner.

Note: To reset the tensioner, use a flat-tip screwdriver of the correct size (1), turning the plunger clockwise, insert it into the tensioner shaft (2).

13. Install tensioner shoe assembly (1) into the tensioner (2) primary drive camshafts.

Attention! If fixture EN 46112 (1) not inserted into the tensioner housing, the tensioner plunger will remain in the locked position and the camshaft chain will not be tensioned, resulting in engine damage.

14. By pressing the shoe assembly, insert it into the housing (2) and lock the primary drive chain tensioner by inserting the EN 46112 tool into the hole provided for it in the side wall of the housing.

15. Slowly release pressure on the primary camshaft drive chain tensioner. The timing chain tensioner must remain in the depressed position.

16. Install on tensioner (2) camshaft primary drive chain new gasket (1).

17. Install bolts (3) through the holes in the tensioner and gasket.

18. Verify that the cylinder block mounting surface for the primary drive chain tensioner is free of nicks or other defects that could affect the seal of the new tensioner gasket.

19. Install the tensioner (2) chains of the primary drive of camshafts and make bolts (1) attachment to the cylinder block.

20. Check the correct position of the tongue (1) gaskets for the chain tensioner of the primary drive of the camshafts.

21. Tighten the bolts (2) camshaft primary drive chain tensioner.

Tighten

Tighten the primary drive chain tensioner mounting bolts to 23 Nm (17 lb-ft).

22. Unlock tensioner (1), by pulling out the tool EN 46112 (2) and free the tensioner shaft.

23. Check alignment of alignment marks (from 1st to 12th) chains of primary drive and secondary drive of camshafts of number of cylinders 2

24. Remove the tool EN 46105 from the camshafts of cylinder banks 2 and 1.

Bank 1 Secondary Camshaft Drive Circuit Components

1. Install the camshaft primary drive circuit components. See «Camshaft Drive Chain Components» in this section.

2. Using the EN-46111 fixture (1) turn the crankshaft clockwise to align the alignment mark (2) on the crankshaft sprocket with a mark (3) on the oil pump housing.

Attention! Rotate the camshafts to fit the EN 46105 tool. This will not require the camshafts to be rotated more than 45 degrees.

3. Install fixture EN 46105-1 (1) on the rear ends of the camshafts (2) cylinder bank 1.

4. Install fixture EN 46105-2 (1) on the rear ends of the camshafts (2) row of cylinders 2.

5. Install on drives (2) variable valve timing and sprocket (3) intermediate shaft chain (1) secondary camshaft drive for cylinder bank 1.

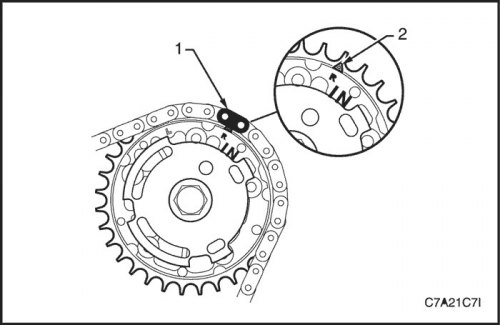

A. Position the secondary camshaft drive chain around the bank 1 intermediate camshaft sprocket, aligning the shiny link (1) chains with a hole (2) in the inner star.

B. Chain both camshaft timing sprockets for bank 1 camshafts.

Attention! When adjusting the position of the chain on the sprockets of the drive for adjusting the valve timing of the camshafts of cylinder bank 1, use the alignment marks in the form of triangles (1), and NOT in the form of circles.

C. Match the shiny link (2) chains with a triangular alignment mark on the sprocket of the drive for regulating the valve timing of the exhaust shaft.

D. Match the shiny link (1) chains with triangular alignment mark (2) on the sprocket of the drive for regulating the valve timing of the intake shaft.

Attention! When installing the chain guide on the bank 1 side, ensure that the bank 1 secondary camshaft drive chain guide is used.

6. Ensure correct selection and orientation of bank 1 secondary camshaft drive chain guide.

7. Place Guide (2) chains.

8. Check the correct selection and orientation of the primary camshaft drive chain guide.

Tighten

Tighten secondary drive chain guide bolts to 23 Nm (17 lb-ft).

Attention! The secondary camshaft drive chain shoe for bank 1 is marked with the letters RH. When installing the shoe on the bank 1 side, use the correct shoe and make sure that the letters RH face the front of the vehicle when installing.

9. Make sure that the secondary camshaft drive chain shoe for bank 1 is correctly selected and oriented.

10. Position shoe (1) chains of the secondary drive of camshafts of a number of cylinders 1.

Tighten

Tighten the secondary camshaft drive chain shoe mounting bolt for cylinder bank 1 to 23 Nm (17 lb-ft).

11. Check correct selection and orientation of bank 1 secondary camshaft timing chain tensioner.

12. Reset the bank 1 secondary camshaft timing chain tensioner.

Note: To reset the tensioner, use a flat-tip screwdriver of the correct size (1), turning the plunger clockwise, insert it into the tensioner shaft (2).

13. install shaft (1) tensioner in the body (2) chain tensioner for the secondary camshaft drive chain 1.

Attention! If fixture EN 46112 (1) not inserted into tensioner housing (2), the tensioner plunger will remain in the locked position and the camshaft timing chain will not be tensioned, resulting in engine damage.

14. Press the tensioner shaft into the housing and block the tensioner by inserting the EN 46112 tool into the hole provided for it in the side wall of the tensioner housing.

15. Slowly release the bank 1 secondary camshaft timing chain tensioner shaft. The tensioner must remain in its original position.

16. Install on tensioner (2) chains of the secondary drive of camshafts of a row of cylinders 1 new lining (1).

17. Install bolts (3) through the holes in the tensioner and gasket.

18. Verify that the bank 1 cylinder head mounting surface for the secondary chain tensioner is free of nicks or other imperfections that could affect the seal of the new tensioner gasket.

19. Install the tensioner (2) chains for the secondary camshaft drive of cylinder bank 1 and install the bolts (1) attachment to the cylinder block.

20. Check the correct position of the tongue (1) tensioner gaskets.

21. Tighten the bolts (2) chain tensioner for the secondary camshaft drive chain 1.

Tighten

Tighten the secondary camshaft timing chain tensioner mounting bolts for cylinder bank 1 to 23 Nm (17 lb-ft).

22. Unlock tensioner (1), by pulling out the tool EN 46112 (2) and release the tensioner plunger.

23. Check alignment of all alignment marks (from 1st to 18th) primary drive circuits and secondary camshaft drive circuits.

24. Remove tools EN 46105 and EN 46105-2 from the camshafts of both cylinder heads.

25. Install the spark plugs. See Part 1F3, Engine Controls - HFV6 3.2L.

26. Install the engine front cover. See «Front cover assembly» in this section.