Removal procedure

Bank 1

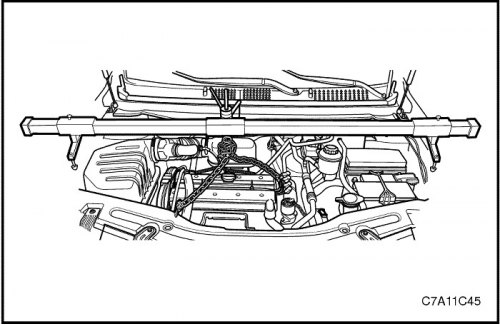

1. Dismantle the engine assembly. follow the paragraph «Complete engine» in this section.

2. Remove intake manifold. See «Inlet manifold assy» in this section.

3. Remove the exhaust manifold. See «Exhaust manifold assy» in this section.

4. Remove the engine wiring harness ground pin bolts from the cylinder head.

5. Remove the bank 1 secondary camshaft drive chain. «Camshaft Drive Chain Components» in this section.

6. Remove the valve timing actuators. See «Camshaft control actuator assembly» in this section.

7. Remove the power steering fluid pipe bolt from the cylinder head.

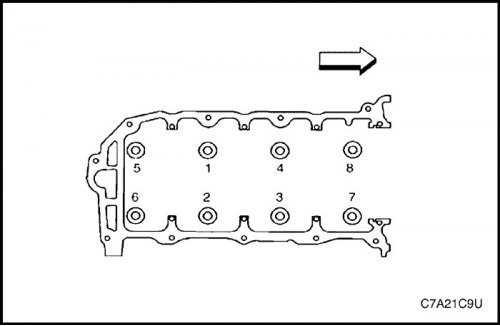

8. Remove bolts (1) cylinder head mountings (eight seats).

Note: No bolt is provided for the hole in cylinder head bank 1.

9. Remove the cylinder head.

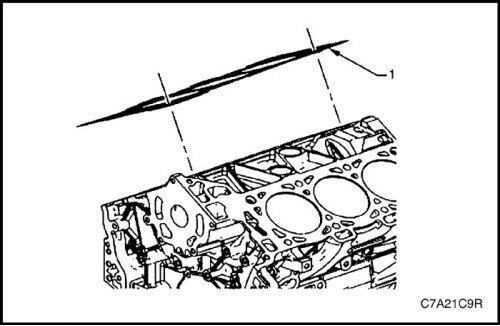

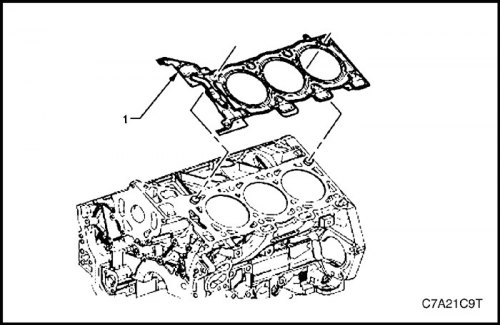

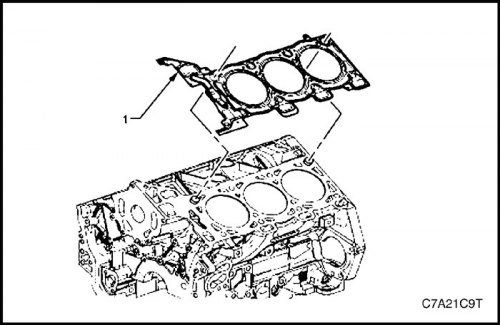

10. Remove and dispose of gasket (1) cylinder heads.

Bank 2

1. Dismantle the engine assembly. follow the paragraph «Complete engine» in this section.

2. Remove intake manifold. See «Inlet manifold assy» in this section.

3. Remove the exhaust manifold. See «Exhaust manifold assy» in this section.

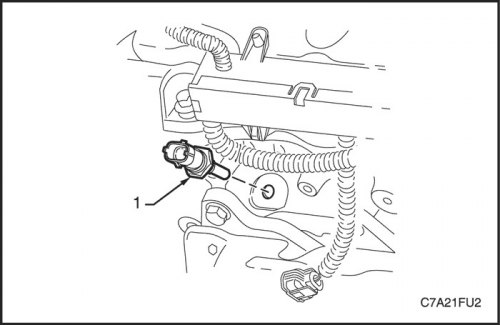

4. Remove the coolant temperature sensor (EATING). See Part 1F3, Engine Controls - HFV6 3.2L.

5. Remove the engine wiring harness ground bolt from the cylinder head.

6. Remove the bank 2 secondary camshaft drive chain. «Camshaft Drive Chain Components» in this section.

7. Remove the valve timing actuators. See «Camshaft control actuator assembly» in this section.

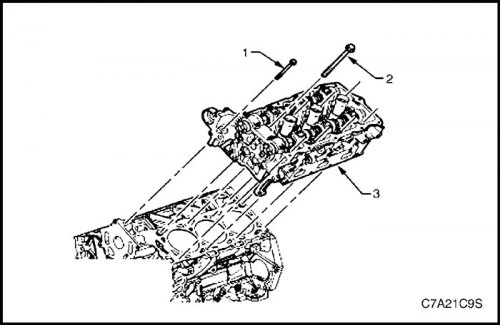

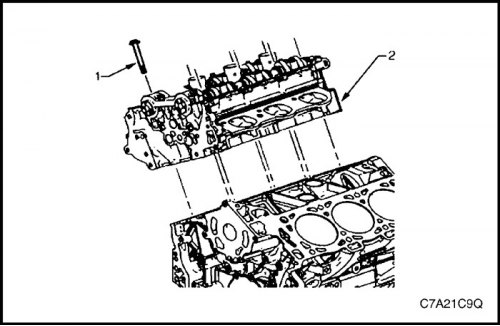

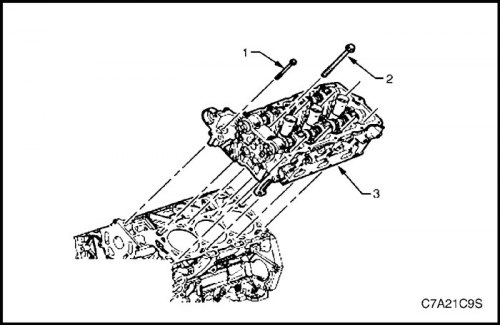

8. Remove front bolts (1) cylinder head mountings (two places).

9. Remove bolts (2) cylinder head mountings (eight seats).

10. Remove cylinder head (3).

11. Remove and dispose of gasket (1) cylinder heads.

Installation procedure

Bank 1

1. Installation is carried out in the reverse order to the removal of parts.

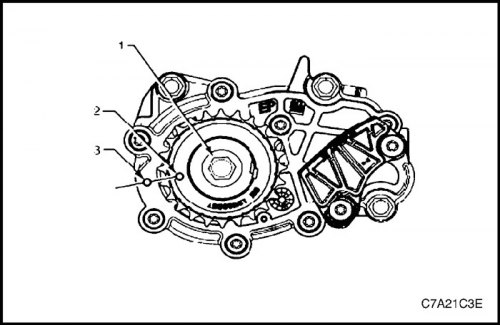

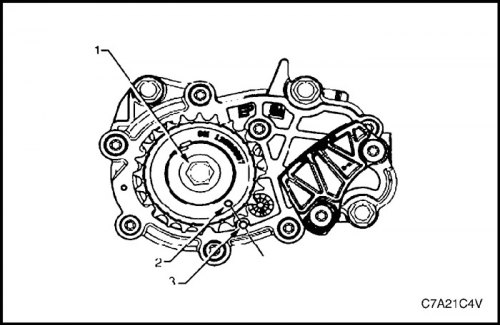

2. Using the EN-46111 fixture (1) to rotate the crankshaft, align the alignment mark (2) on the crankshaft sprocket with a mark (3) on the oil pump housing.

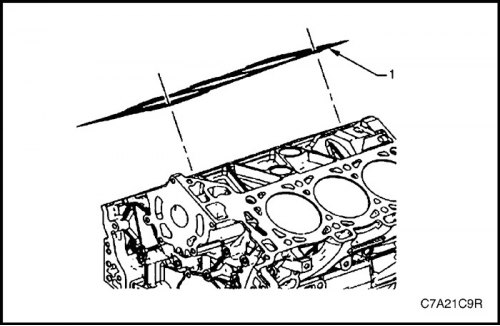

3. Ensure that the joint surface of the block with the cylinder head is clean and that the pins for installing the head are securely fixed on it.

4. Install new gasket (1) cylinder heads, using the dowel pins on the mating surface to secure it.

5. Correctly position the cylinder head in relation to the dowel pins.

6. Install the cylinder head in place.

Note: The cylinder head bolt bosses must be free of oil.

Attention! Do not reuse cylinder head bolts (from 1st to 8th inclusive).

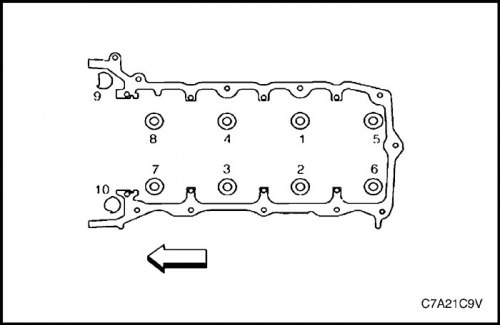

7. Install new bolt (1) cylinder heads (eight seats) and tighten in sequence.

Tighten

Tighten cylinder head bolts to 45 Nm (33 lb-ft) and turn the bolts another 120°using the angle torque indicator KM-470-B.

8. Install all previously removed external parts.

Bank 2

1. Installation is carried out in the reverse order to the removal of parts.

2. Using the EN-46111 fixture (1) to rotate the crankshaft, align the alignment mark (2) on the crankshaft sprocket with a mark (3) on the oil pump housing.

3. Ensure that the joint surface of the block with the cylinder head is clean and that the pins for installing the head are securely fixed on it.

4. Install new gasket (1) cylinder heads, using the dowel pins on the mating surface to secure it.

5. Correctly position the cylinder head in relation to the dowel pins.

6. Install the cylinder head in place.

Note: The cylinder head bolt bosses must be free of oil.

Attention! Do not reuse cylinder head bolts (from 1st to 8th inclusive).

7. Install new bolt (1) cylinder heads (eight places) and tighten in sequence.

Tighten

Tighten cylinder head bolts to 45 Nm (33 lb-ft) and turn the bolts another 120°using the angle torque indicator KM-470-B.

8. Install front bolt (2) cylinder heads (two places) and tighten in sequence (9 and 10).

Tighten

Tighten front cylinder head bolts to 15 Nm (11 lb-ft) and turn each bolt another 60°using the KM-470-B angle torque indicator.

9. Install all previously removed external parts.