Engine

The V6 engine is a V-twin, closed-V cylinder block, die-cast aluminum alloy with extended skirt, cast iron cylinder liners, an internally balanced crankcase, full-length water jackets, and six-bolt main bearing caps each.

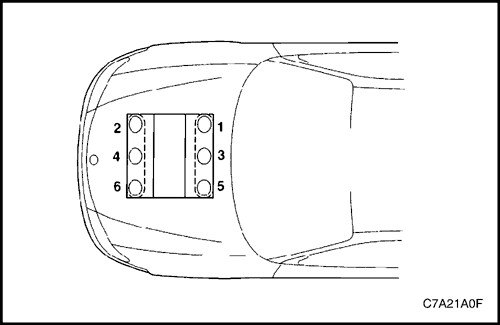

The cylinders form two rows of three cylinders each, which are located at an angle of 60 degrees to each other. The back row consists of cylinders 1-3-5 (ROW 1), and the front row - from cylinders 2-4-6 (ROW 2).

The cylinders work in the order 1-2-3-4-5-6. Each aluminum cylinder head has hardened valve seats and four valves per cylinder: two intake and two exhaust. Two camshafts are used to actuate the valves (two camshafts located on top) per row of cylinders - one for intake and exhaust valves. Smooth control of the valve timing is provided using four drives installed at the front ends of all camshafts.

The crankshaft is made of forged steel. The crankshaft position sensor uses a chopper gear pressed into the rear end of the crankshaft. The connecting rods are made of powdered metal, and the connecting rod caps are chipped during the manufacturing process. This provides a stronger, visually line-free connection between the stem and the cover.

Cleanliness and care

An automobile engine is a combination of many turned, honed, polished and lapped surfaces with tolerances measured in ten-thousandths of a millimeter. When servicing engine parts, cleanliness and care are important. During assembly, a thick layer of engine oil is applied to the rubbing surfaces to protect and lubricate the surfaces during the initial period of operation. Proper cleaning and protection of machined surfaces and friction parts is part of the repair procedure. It is considered standard repair shop practice, even if not specifically stated.

Once the valve train components have been removed for service, they must be maintained in good order. They should be installed in the same places and with the same mating surfaces as before dismantling. Disconnect the battery cables before carrying out major work on the engine. If the cable is not disconnected, cable harnesses or other electrical parts may be damaged.

Maintenance without dismantling from the engine

Attention! Disconnect the negative battery cable before removing or installing any electrical components, or if tools or equipment may come into contact with exposed electrical terminals. Disconnecting the cable will help to avoid injury and mechanical damage to the car. The ignition must be disabled unless otherwise specified.

Note: When removing the air filter, be sure to cover the intake port. This measure will protect against accidental entry of foreign material that can enter the cylinder through the intake port and cause severe damage when the engine is started.