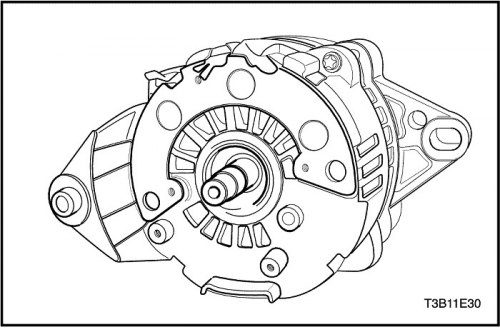

Disassembly procedure

1. Remove the generator. follow the paragraph «Generator» Car maintenance of this section.

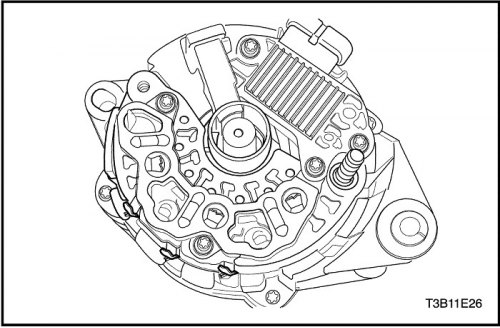

2. Make a mark on the front side to facilitate subsequent collection.

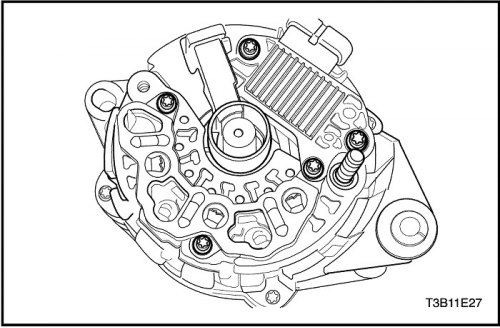

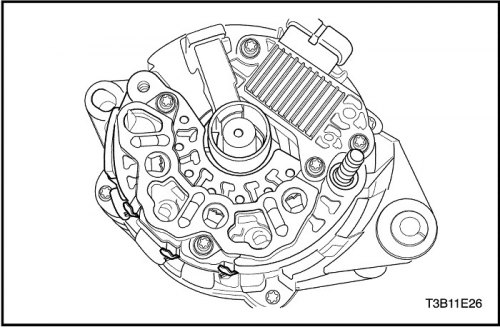

3. Remove the plastic cover with a lever, releasing the stator connector.

Note: If the starter connectors are not welded, melt the wires. Avoid excessive heat as this can damage the diodes in the bridge rectifier.

4. Remove the stator connectors from the bridge rectifier by cutting off the wires.

5. Remove the baffle with a lever.

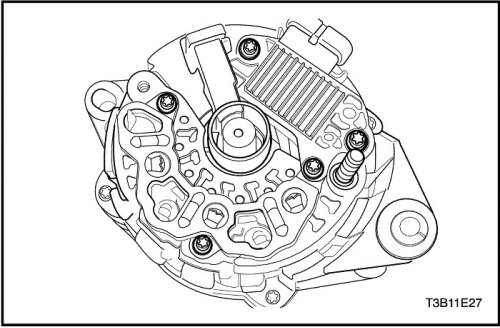

6. Remove the rectifier/regulator/brush holder screws.

7. Remove the brush holder and regulator.

Important: If the brush can be reused, reassemble the brush with the locking pin holder after cleaning it with a soft cloth.

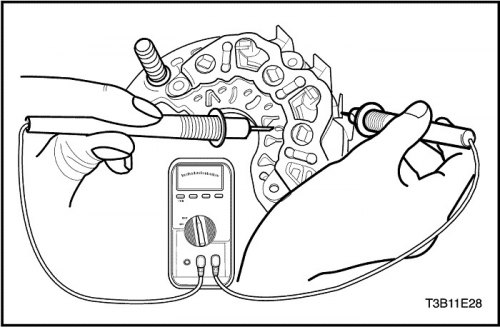

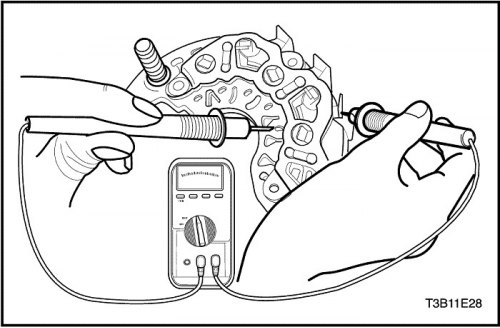

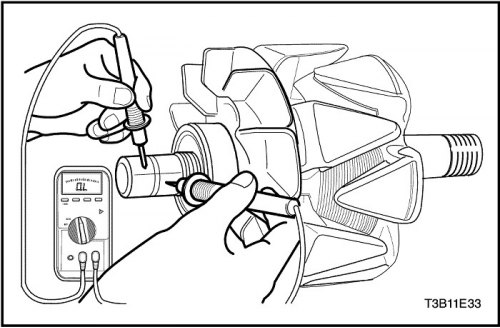

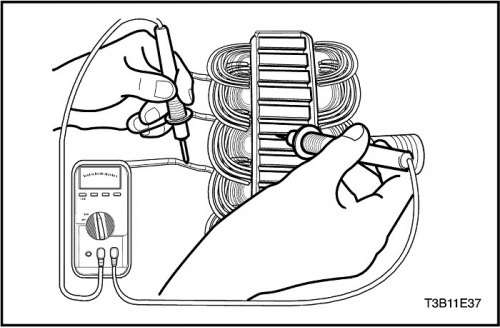

8. Test the bridge rectifier by connecting the leads of an ohmmeter to the rectifier and heatsink.

9. Check again by connecting the ohmmeter leads in reverse order.

10. Replace bridge rectifier if readings are the same.

11. Check the two remaining diodes after the above procedure.

Note: Some types of ohmmeters are not suitable for testing bridge diodes. In this case, consult the manufacturer to check the capacitance.

12. Test the diodes by connecting the leads of an ohmmeter to the rectifier and baseplate connectors. Replace bridge rectifier if readings are the same.

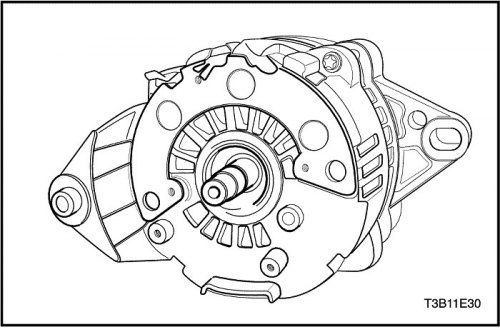

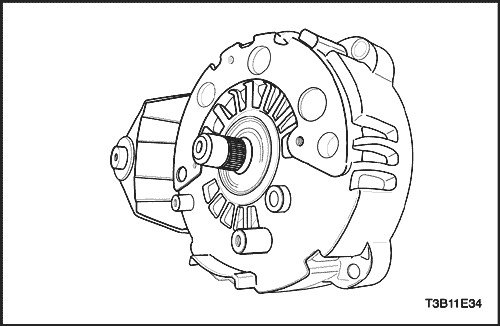

13. Remove the generator through screws.

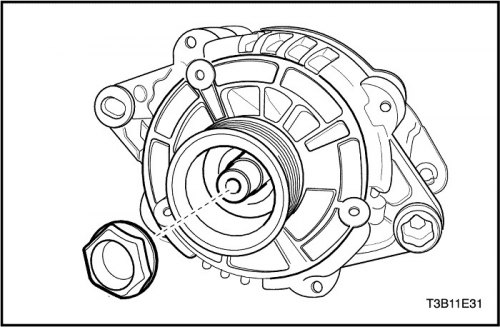

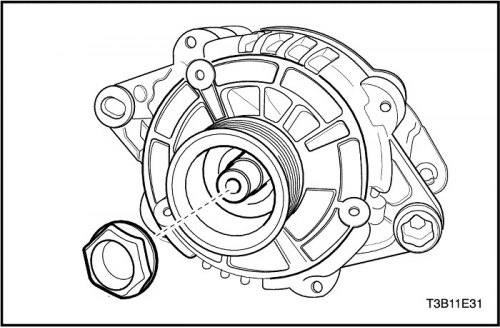

Important: The tightening torque for this nut is 81Nm (60 lb-ft), the nut usually cannot be unscrewed by hand.

14. Remove the bearing nut at the drive end of the generator.

15. Remove pulleys and flanges.

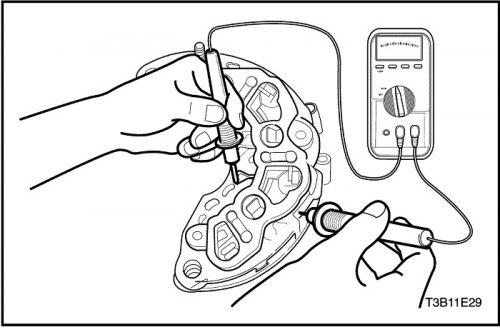

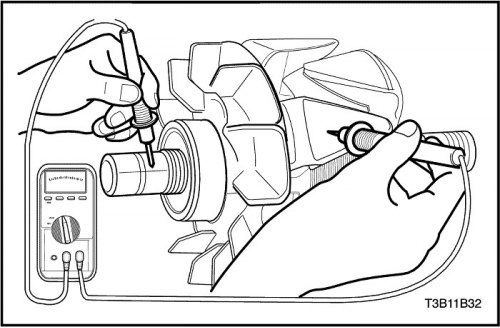

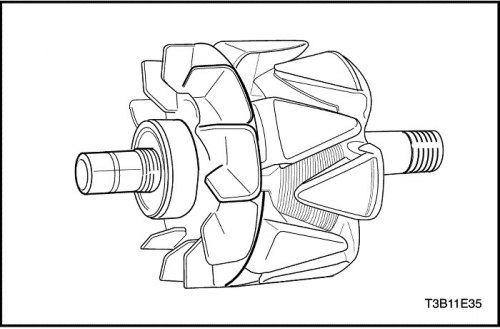

16. Check the rotor for an open circuit using an ohmmeter on the drive side end piece. The reading must be high enough, otherwise replace the rotor.

17. Check rotor for open circuit and short circuit. The reading should be between 1.7 and 2.3 ohms, otherwise the rotor needs to be replaced.

18. Remove the end piece from the shaft.

19. On vehicles with an internal alternator fan, remove the end piece and fan.

20. Remove the rotor.

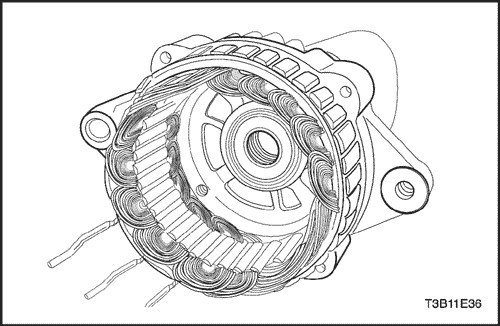

21. Remove the stator.

22. Check the stator for an open circuit using an ohmmeter.

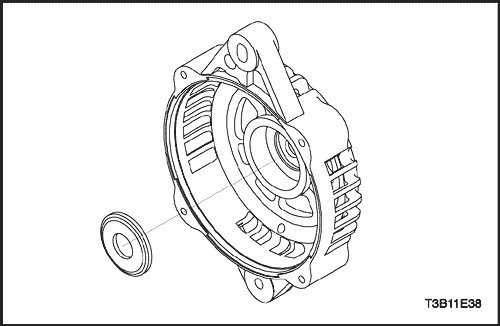

23. Remove the ring on the end piece on the slip ring side.

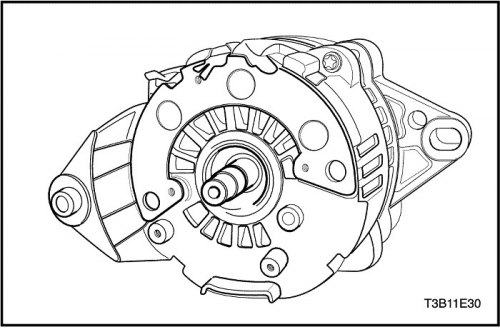

Assembly procedure

1. Install a new ring in the end piece on the side of the slip ring.

2. Install the stator.

3. Install the rotor shaft with the end piece into the slip ring assembly so that the gap between the outer race and the end piece frame is 1.9 mm (0,075 in.).

4.. Install the alternator through screws.

Tighten

Tighten the through screws of the alternator to 10 Nm (89 lb-in).

5. Mount the fan, flanges and pulley on the rotor shaft and secure with a nut.

Tighten

Tighten the alternator drive end bearing nut to 81 Nm (60 lb-ft).

6. Install the generator. follow the paragraph «Generator» Car maintenance of this section.

7. Weld the brush holder terminal to the regulator terminal if removed.

8. Lock the brush holder with the locking pin and weld the regulator/brush holder terminal to the rectifier terminal.

9. Apply silicone grease between bridge rectifier and end piece to dissipate heat.

10. Tighten the screws holding the rectifier regulator/brush holder to the end piece.

11. Drive the protective cover into the brush with the pin.

Note: Take precautions to protect the vehicle by protecting the bridge rectifier diode from excessive welding heat.

12. Weld the bridge rectifier connectors.