Necessary equipment

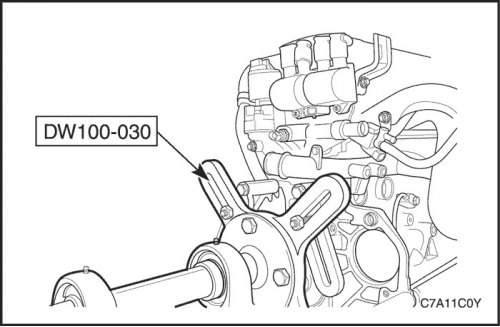

DW100-030 Engine overhaul stand

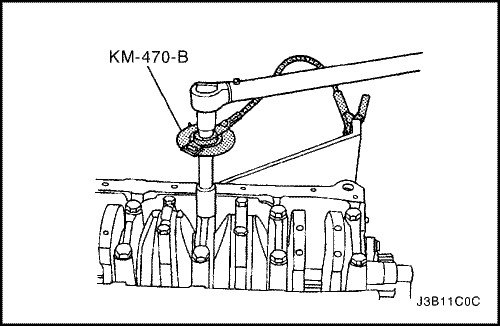

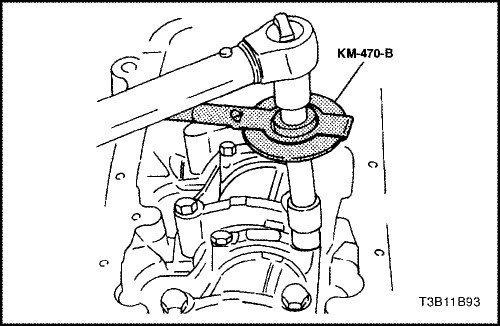

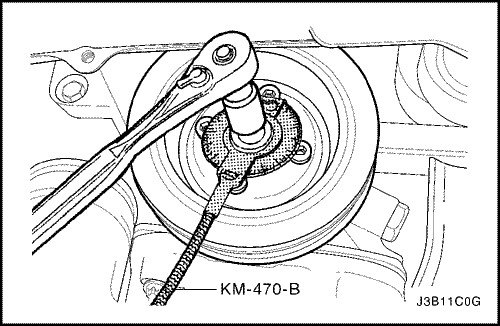

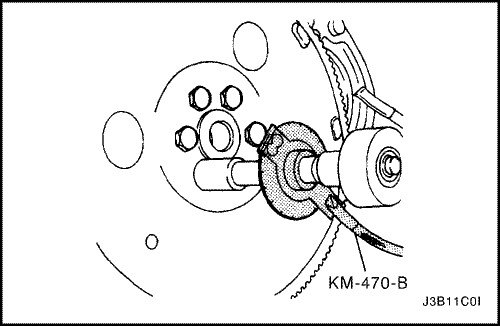

KM-470-B Angle Torque Indicator

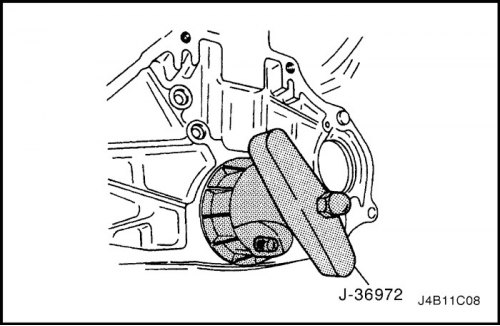

J–36972 or KM–635 Crankshaft rear oil seal

Note: Be especially careful not to scratch, dent or damage the camshafts.

Disassembly procedure

1. Remove the engine. follow the paragraph «Engine» in this section.

2. Remove the flywheel or flex plate screws.

3. Remove flywheel or flexible plate.

4. Remove the crankshaft rear oil seal.

5. Install the engine on the engine overhaul stand DW100-030.

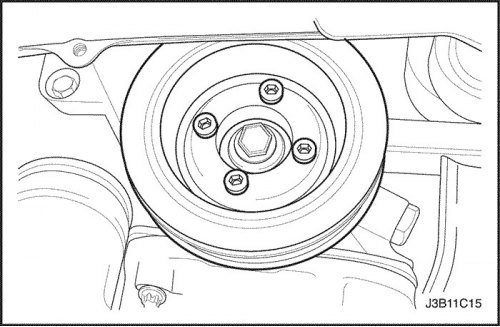

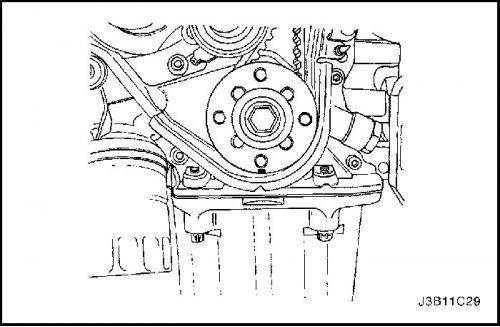

6. Remove the crankshaft pulley screws.

7. Remove the crankshaft pulley.

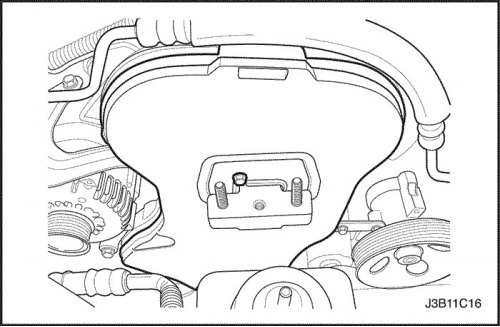

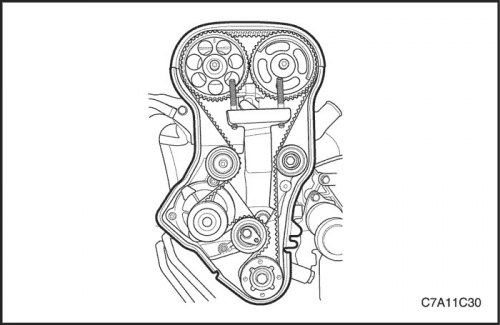

8. Remove the timing belt front cover screws

9. Remove the timing belt front cover

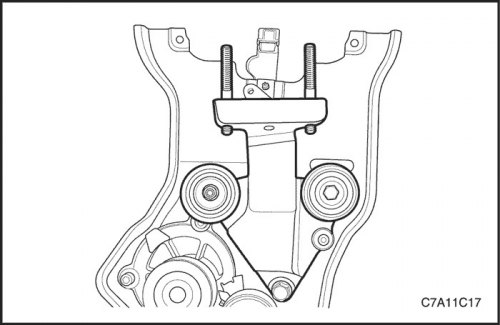

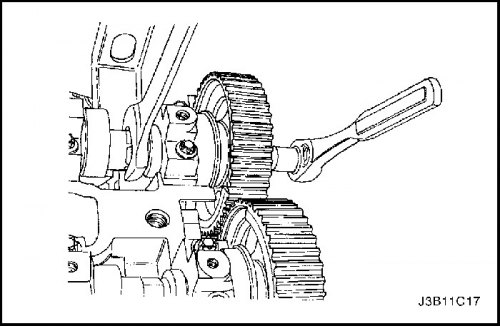

10. Loosen the timing belt automatic tensioner screw.

11. Turn the hex head of the timing belt auto-tensioner clockwise to loosen the tension.

12. Remove the screw and nut of the timing belt idler pulley.

13. Remove the timing belt idler pulleys.

14. Remove the timing belt.

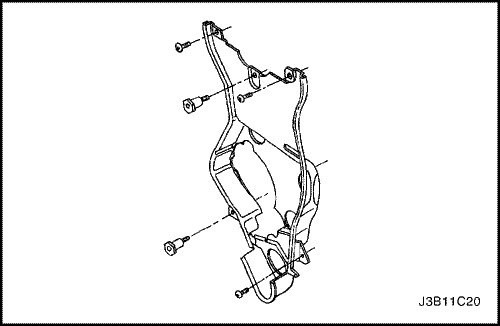

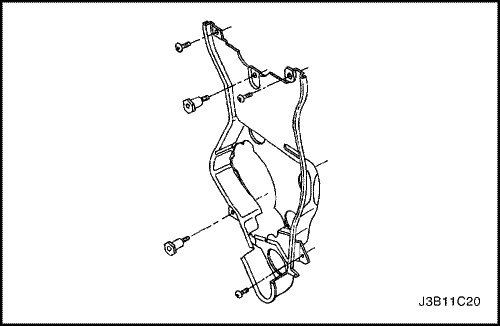

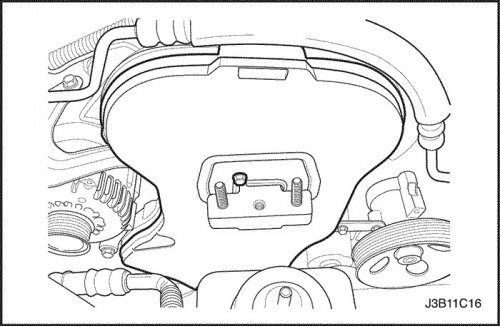

15. Remove the engine mount adapter support bracket bolts.

16. Remove the engine mount adapter support bracket.

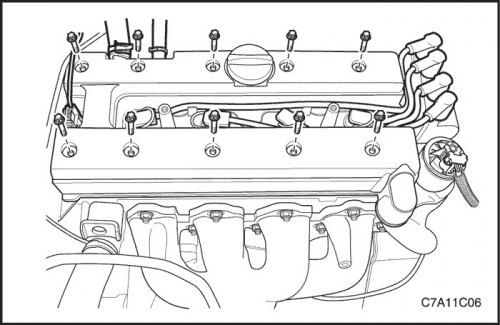

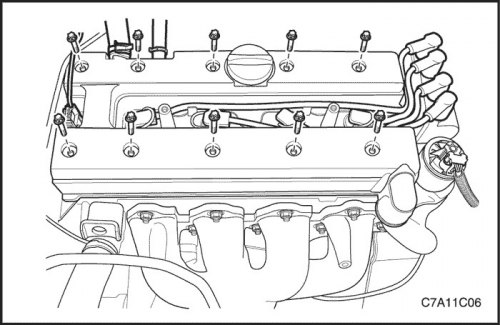

17. Remove ignition wires from spark plugs.

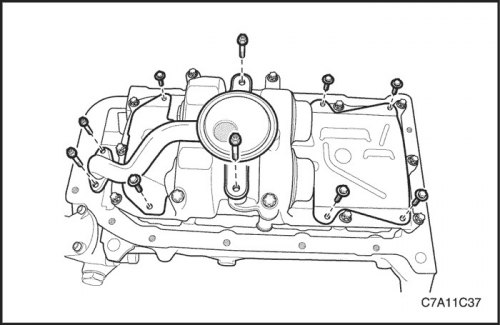

18. Remove the cylinder head cover and gasket. See «cylinder head cover» in this section.

Note: Be especially careful not to scratch, dent or damage the camshafts.

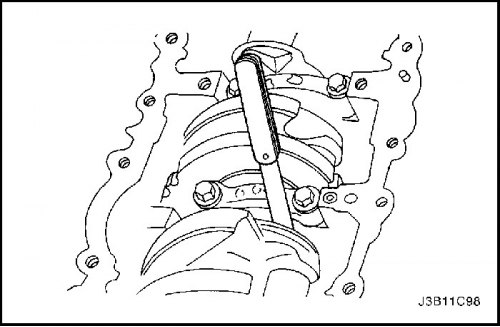

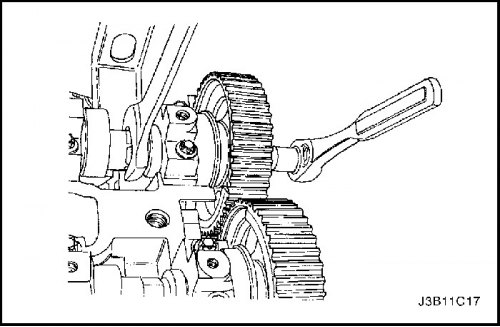

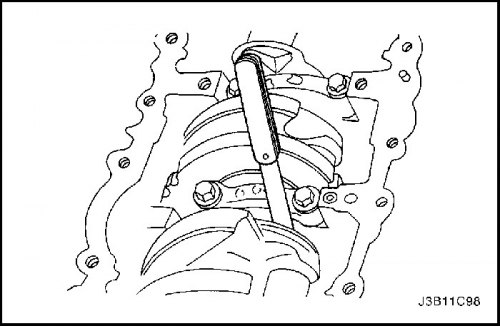

19. While firmly holding the intake camshaft, remove the intake camshaft gear screw.

20. Remove the intake camshaft gear.

21. While firmly holding the exhaust camshaft, remove the exhaust camshaft gear screw.

22. Remove the exhaust camshaft gear.

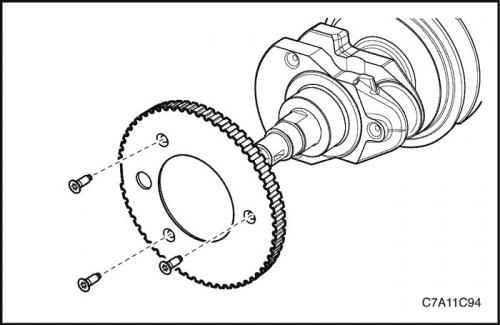

23. Remove the crankshaft gear.

24. Loosen the bolts of the timing belt rear cover and remove the cover.

25. Turn the engine on the engine overhaul stand DW100-030.

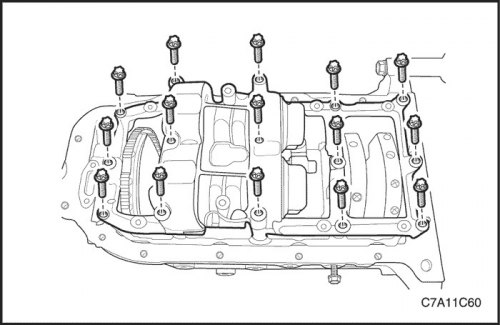

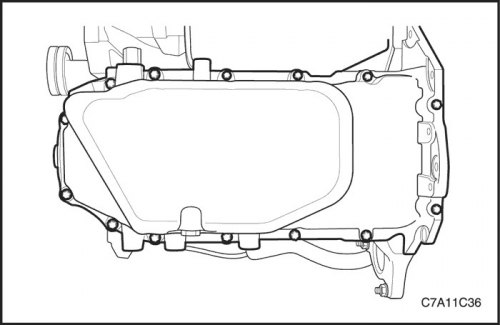

26. Remove the oil pan retaining screws.

27. Remove the oil pan.

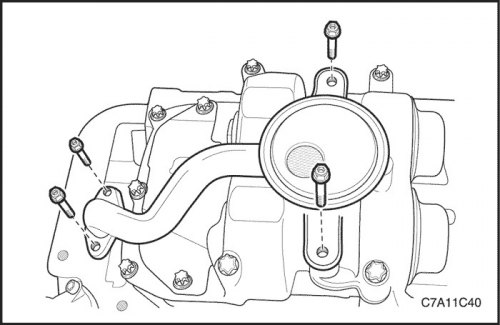

28. Remove the oil suction pipe screws.

29. Dismantle the oil suction tube with O-ring.

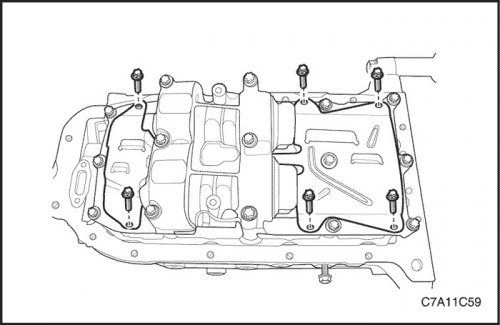

30. Loosen the oil pan scraper bolts.

31. Remove the oil pan scrapers.

32. Loosen the crankshaft balancer assembly retaining bolts.

33. Remove the crankshaft balancer assembly.

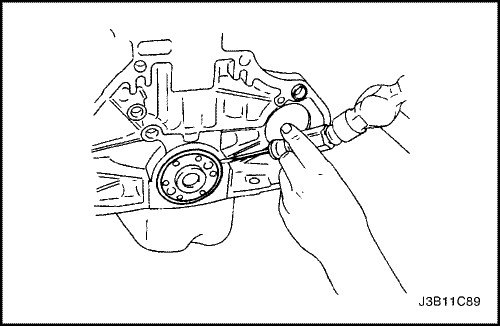

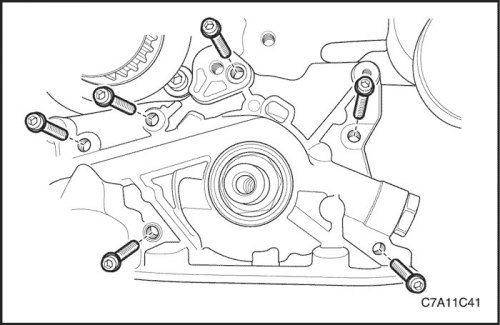

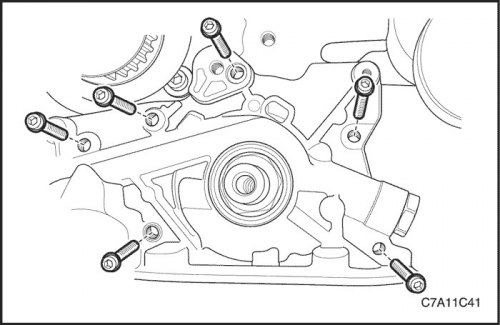

34. Remove the oil pump retaining screws.

35. Remove the oil pump.

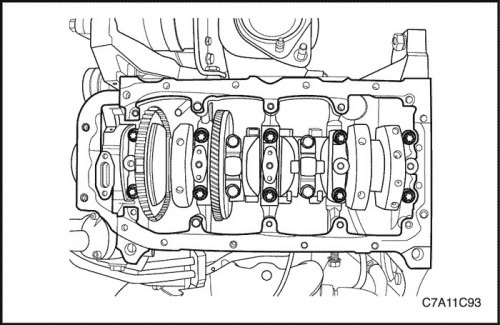

36. Write down the sequence for installing the connecting rod bearing caps.

37. Remove the connecting rod bearing cap screws for all pistons.

38. Remove the connecting rod bearing caps and lower the connecting rod bearings.

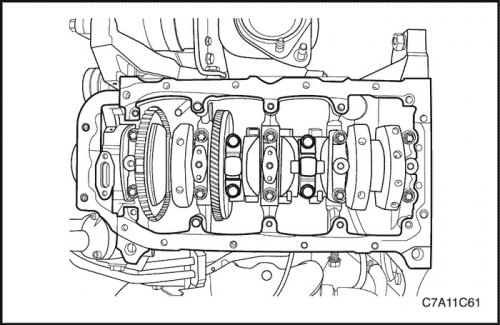

39. Record the sequence for installing the crankshaft bearing caps.

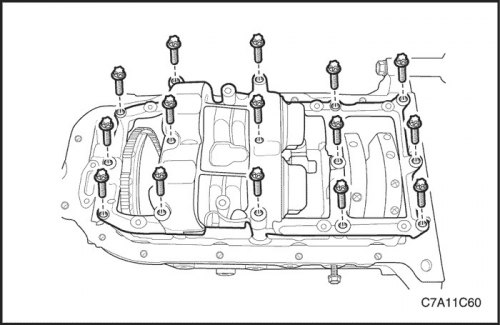

40. Remove the main bearing cap screws.

41. Remove the main bearing caps and lower main bearings.

42. Remove the crankshaft.

43. Clean parts if necessary.

Assembly procedure

1. Lubricate the main bearings with engine oil.

2. When replacing the crankshaft, transfer the breaker gear to the new crankshaft.

3. Install the crankshaft.

4. Install the lower main bearings into the bearing caps.

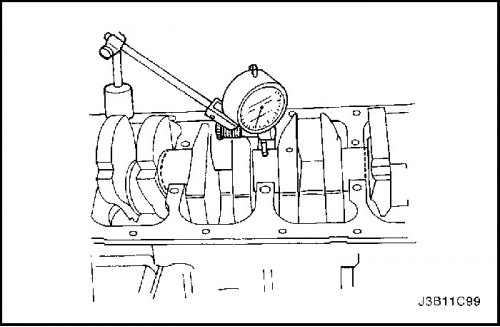

5. Check the end play of the crankshaft with main bearings installed.

6. Check the permissible axial play of the crankshaft. follow the paragraph «Engine Specifications» in this section.

7. With the crankshaft installed in the front and rear main bearings, check the crankshaft center journal for allowable eccentricity (beat). follow the paragraph «Engine Specifications» in this section.

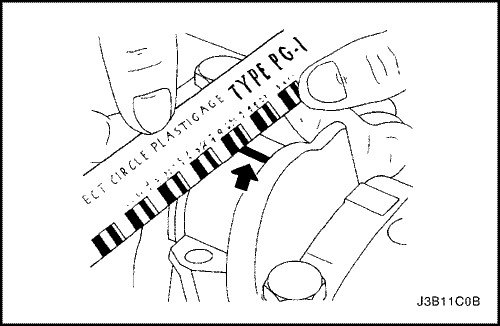

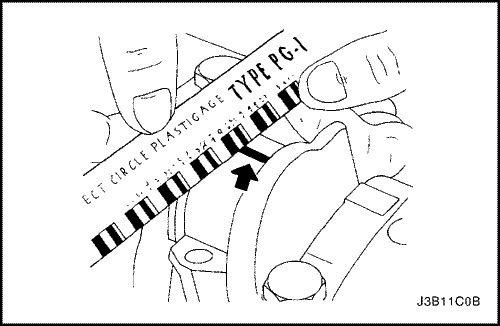

Important: Lubricate the crankshaft journals with grease and lightly lubricate the main bearings so that the plastic gauge wire does not break when the main bearing caps are removed.

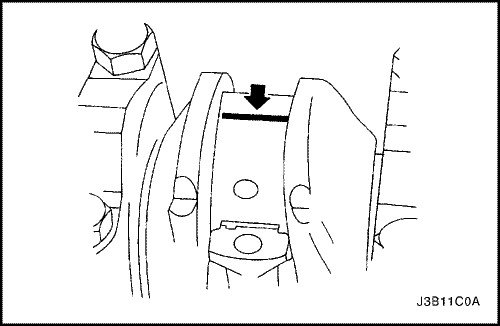

8. Check all main bearing clearances using a commercially available plastic gauge wire (elastic gauge wire).

9. Cut the plastic gauge wire to the size of the bearing width. Lay it axially between the crankshaft journals and the main bearings.

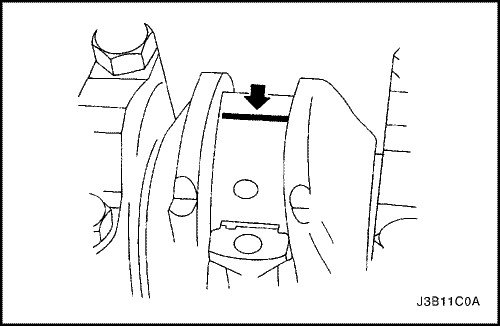

10. Install the main bearing caps and screws.

Tighten

Tighten the main bearing cap bolts to 50 Nm (37 lb-ft) plus 45°and 15°.

11. Remove the main bearing cap and cap screws.

12. Measure the width of the flattened plastic gauge wire using a ruler. (Plastic gauge wire available for various tolerances).

13. Check bearing clearances for permitted tolerances. follow the paragraph «Engine Specifications» in this section.

14. Apply a bead of adhesive to the main bearing cap grooves.

15. Install the main bearing caps to the cylinder block.

16. Tighten the main bearing caps with new screws.

Tighten

Tighten the main bearing cap bolts to 50 Nm (37 lb-ft), using a torque wrench. Using the angle torque gauge KM-470-B, tighten the main bearings an additional 45°and 15°.

Important: Lubricate the connecting rod bearing journals and lightly grease the connecting rod bearings so that the plastic gauge wire does not break when the connecting rod bearing caps are removed.

17. Check all connecting rod bearing clearances using a commercially available plastic gauge wire (elastic gauge wire).

18. Cut the plastic gauge wire to the width of the connecting rod bearing. Place it axially between the connecting rod journals and the connecting rod bearings.

19. Install the connecting rod bearing caps.

Tighten

Tighten the connecting rod bearing cap screws to 35 Nm (26 lb-ft), using a torque wrench. Using the angle torque gauge KM-470-B, tighten the connecting rod bearing cap bolts an additional 45°plus 15°.

20. Remove the connecting rod bearing caps.

21. Measure the width of the flattened plastic gauge wire using a ruler. (Plastic gauge wire available for various tolerances).

22. Check bearing clearances for permitted tolerances. follow the paragraph «Engine Specifications» in this section.

23. Install the connecting rod bearing caps to the connecting rods.

24. Tighten the connecting rod bearing caps with new screws.

Tighten

Tighten the connecting rod bearing cap screws to 35 Nm (26 lb-ft), using a torque wrench. Using the angle torque gauge KM-470-B, tighten the connecting rod bearing cap bolts an additional 45°plus 15°.

25. Install the oil pump.

26. Install the oil pump retaining screws.

Tighten

Tighten the oil pump retaining bolts to 10 Nm (89 lb-in.).

27. Install the crankshaft balancer assembly.

28. Install the crankshaft balancer assembly retaining bolts.

Tighten

Tighten the crankshaft balancer assembly retaining bolts to 20 Nm (15 lb-ft) and turn the bolts another 45°using the angle torque indicator KM-470-B.

29. Install the oil pan scrapers.

30. Install the oil pan scraper retaining bolts.

Tighten

Tighten the oil pan scraper retaining bolts to 8 Nm (71 lb-in.).

31. Install oil suction pipe with O-ring.

32. Install the oil suction tube retaining bolts.

Tighten

Tighten oil suction tube bolts to 8 Nm (71 lb-in.).

33. Apply sealant to the mating surfaces of the oil pan.

34. Install the oil pan.

35. Install the oil pan retaining screws.

Tighten

Tighten the oil pan retaining bolts to 10 Nm (89 lb-in.).

36. Turn the engine on the engine overhaul stand DW100-030.

37. Install the timing belt rear cover.

38. Install the timing belt rear cover screws.

Tighten

Tighten the timing belt rear cover bolts to 7 Nm (62 lb-in.).

39. Install the crankshaft gear and bolt.

Tighten

Tighten the crankshaft gear bolt to 135 Nm (100 lb-ft) plus 30°plus 10°using the angle torque indicator KM-470-B.

40. Install the engine mount adapter support bracket and bolts.

Tighten

Tighten the engine mount adapter support bracket retaining bolts to 45 Nm (33 lb-ft).

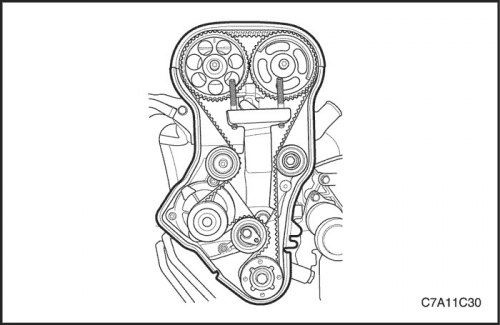

41. Install the timing belt idler pulley.

42. Install the timing belt idler pulley screw and nut.

Tighten

Tighten the timing belt idler pulley screw to 25 Nm (18 lb-ft).

Note: Be especially careful not to scratch, dent or damage the camshafts.

43. Install the intake camshaft gear.

44. While holding the intake camshaft firmly, remove the intake camshaft screw and gear.

Tighten

Tighten the intake camshaft gear bolt to 50 Nm (37 lb-ft) plus 60°and 15°using the angle torque indicator KM-470-B.

45. Install the exhaust camshaft gear.

46. While firmly holding the exhaust camshaft, remove the screw and exhaust camshaft gear.

Tighten

Tighten the exhaust camshaft gear bolts to 50 Nm (37 lb-ft) plus 60°and 15°using the angle torque indicator KM-470-B.

47. Install the automatic timing belt tensioner.

Tighten

Tighten the timing belt auto-tensioner screws to 25 Nm (18 lb-ft).

48. Install the timing belt. follow the paragraph «The drive belt of the gas distribution mechanism» in this section.

49. Adjust the timing belt tension. follow the paragraph «Checking and adjusting the tension of the timing belt» in this section.

50. Apply a small amount of sealant to the corners of the front camshaft head and where the top of the rear cylinder head cover attaches to the cylinder head gasket.

51. Install the cylinder head cover gasket and cylinder head cover gasket. follow the paragraph «Cylinder head and gasket» in this section.

Tighten

Tighten cylinder head cover bolts to 8 Nm (71 lb-in.).

52. Connect the ignition wires to the spark plugs.

53. Connect the breather and positive crankcase ventilation hose to the cylinder head cover.

54. Install the timing belt front cover.

55. Install the timing belt front cover screws.

Tighten

Tighten the timing belt front cover bolts to 6 Nm (53 lb-in.).

56. Place a lifting device on the engine support bracket and raise the engine assembly to take the load off the DW100-030.

57. Remove the engine from the engine overhaul stand DW100-030.

58. Install a new crankshaft rear oil seal using J-36792 rear crankshaft oil seal installer.

59. Install flywheel or flexible plate.

60. Install flywheel or flex plate bolts.

Tighten

Tighten flywheel bolts to 65 Nm (48 lb-ft).

Using the angle torque gauge KM-470-B, tighten the flywheel bolts an additional 30°plus 15°.

For automatic transaxle assembly, tighten flex plate bolts to 45 Nm (33 lb-ft).

61. Install the engine. follow the paragraph «Engine» in this section.