Necessary equipment

- KM-470-B Angle Torque Indicator

- DW 110–060 Engine clamp

Removal procedure

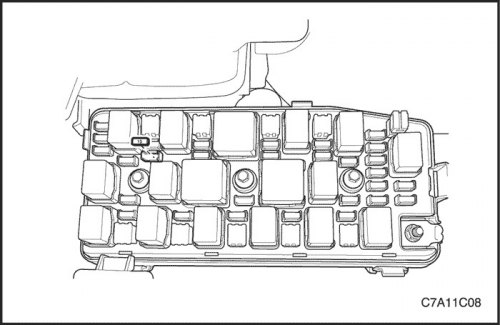

1. Remove the fuel pump fuse.

2. Start the engine. After stopping the engine, crank the engine for 10 seconds to relieve pressure in the fuel system.

3. Disconnect the negative battery cable.

4. Drain the engine coolant. See Section 1D2, Engine Cooling System - FAM II 2.4D.

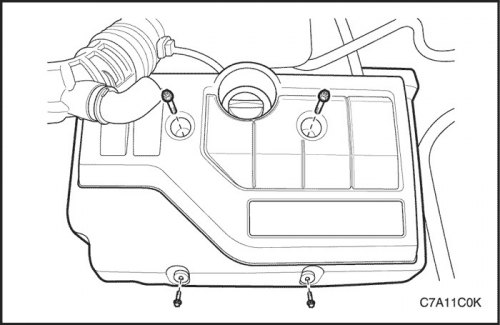

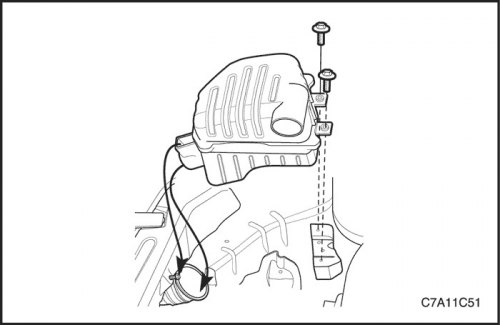

5. Remove the air filter assembly. See «Air filter assembly» in this section.

6. Remove the engine cover and engine cover bracket.

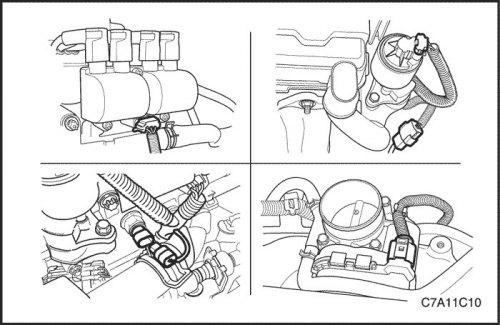

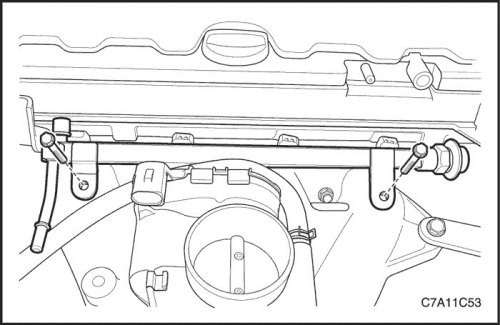

7. Disconnect the breather hose and the positive crankcase ventilation hose from the cylinder head cover.

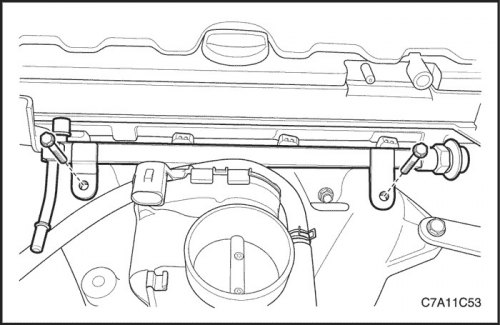

8. Loosen the clamp and remove the resonator from the electronic throttle body.

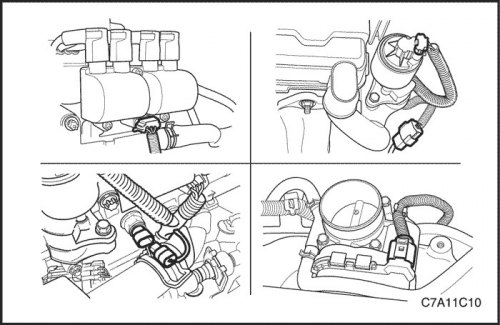

9. Disconnect the direct ignition connector (DIS).

10. Disconnect the oxygen control sensor connector.

11. Disconnect the electronic throttle control module connector (ETC).

12. Disconnect the coolant temperature sensor connector (CTS).

13. Disconnect the EGR valve connector (EGR).

14. Remove the right front wheel. Follow Section 2E, Tires and wheels.

15. Remove the front engine cover from the right front wheel side.

16. Remove the flexed auxiliary drive belt. See «Accessory drive belt» in this section.

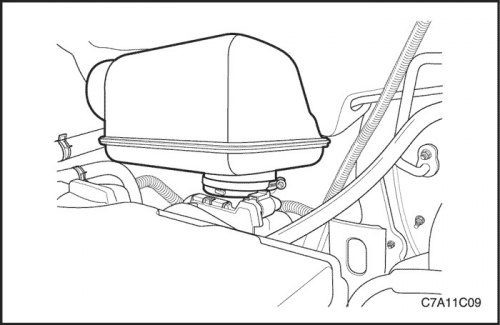

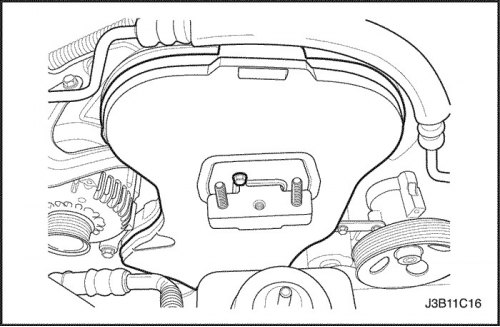

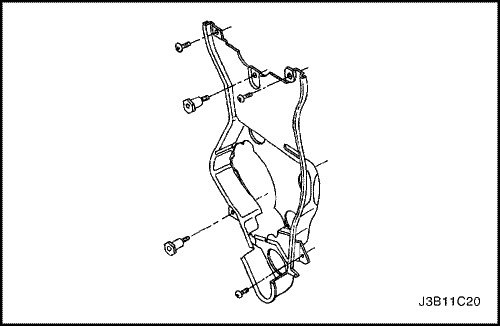

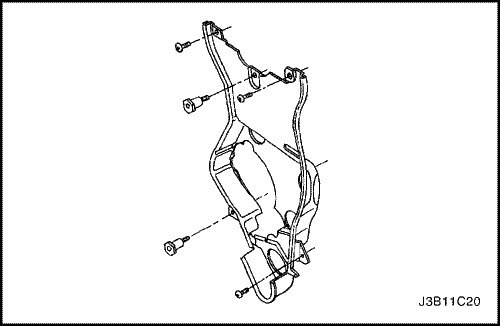

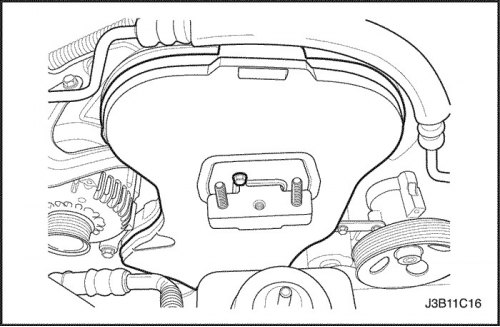

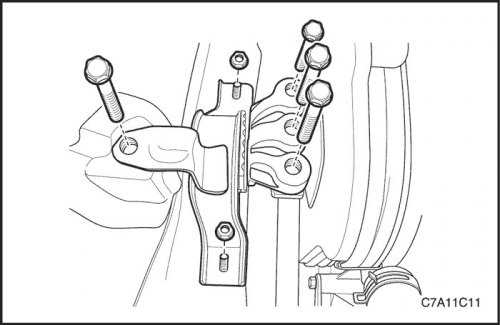

17. Install engine jig assembly DW110-060.

18. Remove the engine mount. See «Engine mount» in this section.

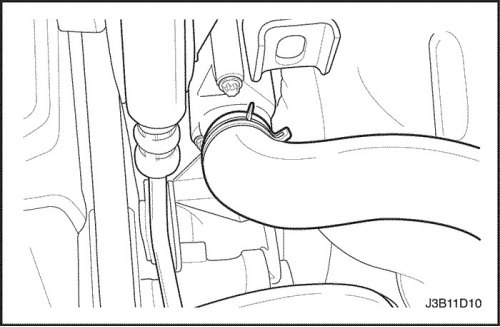

19. Disconnect the upper radiator hose from the thermostat housing.

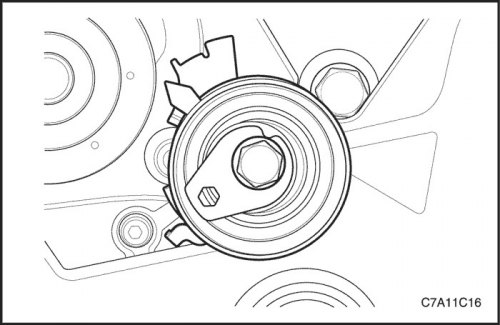

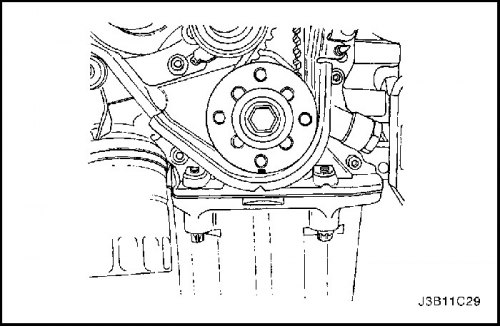

20. Remove the crankshaft pulley screws.

21. Remove the crankshaft pulley.

22. Remove the timing belt front cover screws

23. Remove the timing belt front cover

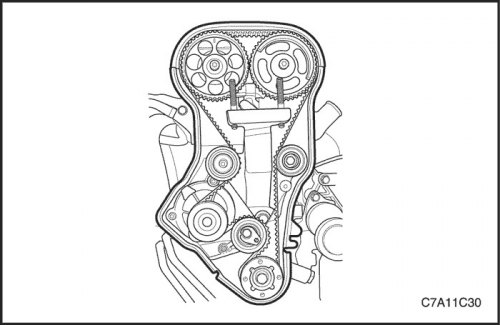

24. Remove the timing belt. follow the paragraph «The drive belt of the gas distribution mechanism» in this section.

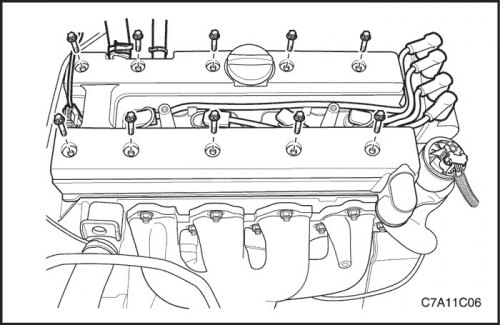

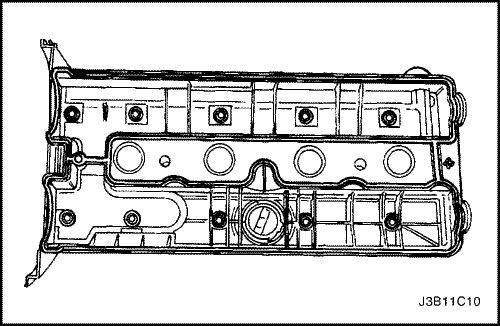

25. Remove the cylinder head cover and gasket. See «cylinder head cover» in this section.

Note: Be especially careful not to scratch, dent or damage the camshafts.

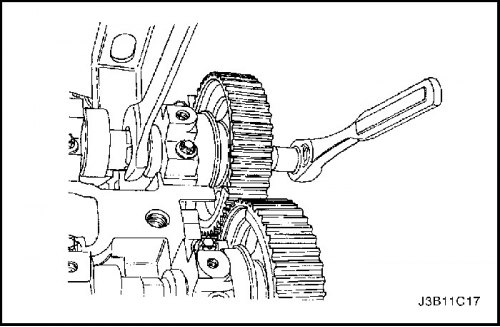

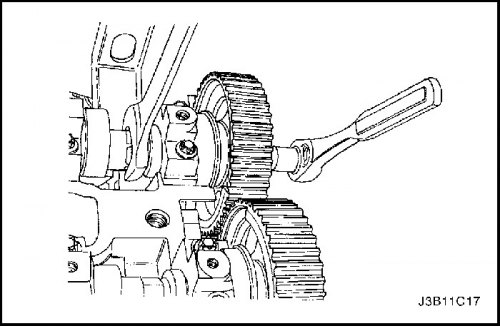

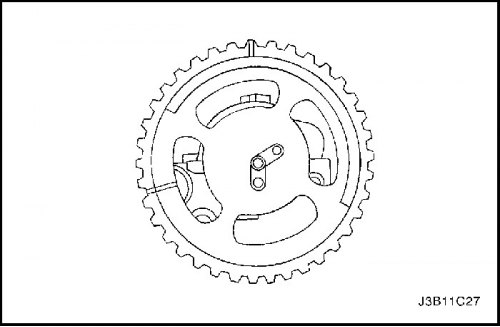

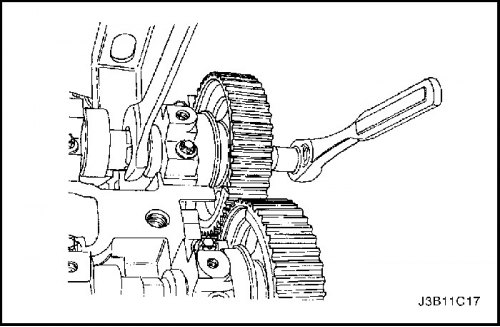

26. While holding the intake camshaft firmly, remove the intake camshaft gear bolts.

27. Remove the intake camshaft gear.

28. While holding the exhaust camshaft firmly, remove the exhaust camshaft gear bolts.

29. Remove the exhaust camshaft gear.

30. Remove the timing belt auto-tensioner screws.

31. Remove the automatic timing belt tensioner.

32. Remove the screw and nut of the timing belt idler pulley.

33. Remove the timing belt idler pulley.

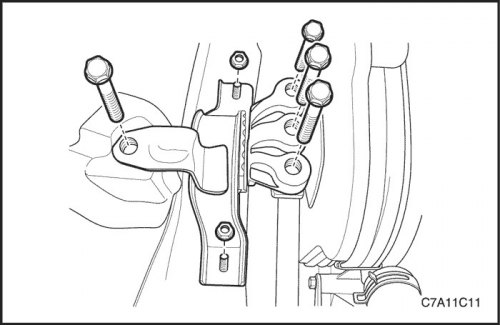

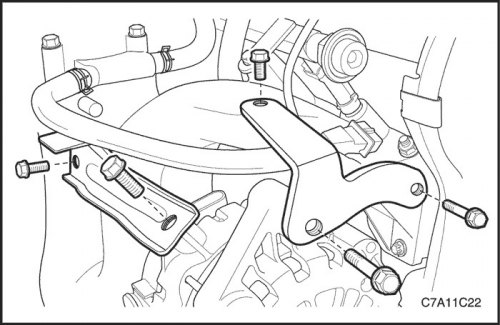

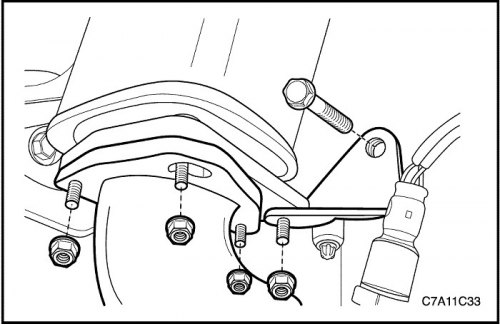

34. Remove the engine mount adapter support bracket bolts.

35. Remove the engine mount adapter support bracket.

36. Remove the crankshaft gear.

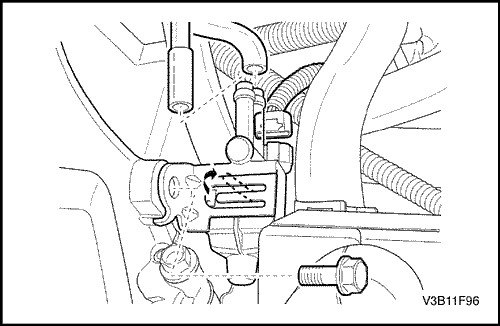

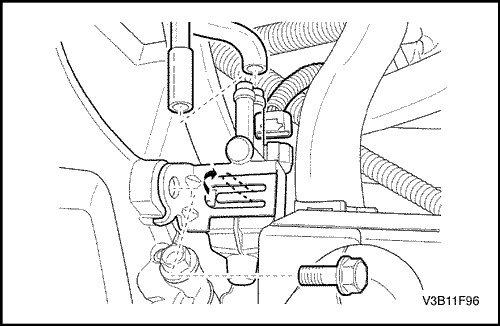

37. Remove the camshaft position sensor (CMP).

38. Remove the timing belt cover screws.

39. Remove the timing belt rear cover.

40. Loosen the nuts securing the catalytic converter to the exhaust pipe of the muffler.

41. Remove the bolt and nut from the muffler exhaust pipe mounting bracket.

42. Remove the front silencer pipe from the catalytic converter. See Section 1G2, Exhaust System - FAM II 2.4D.

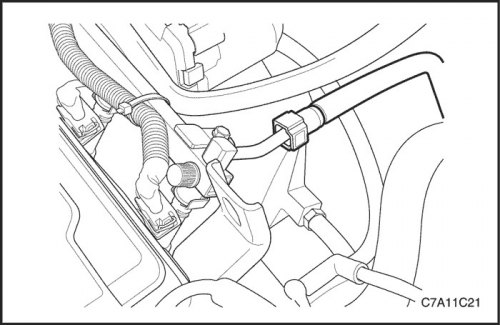

43. Disconnect all necessary vacuum hoses.

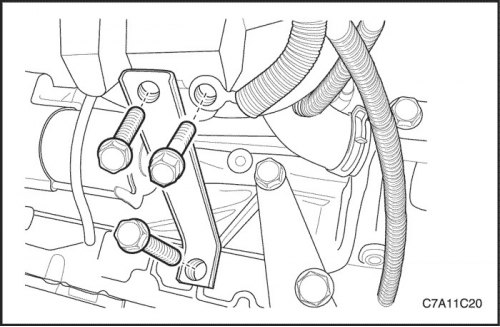

44. Remove the intake manifold support bracket bolts and remove the bracket.

45. Remove the retaining bolt of the ground terminal from the intake manifold.

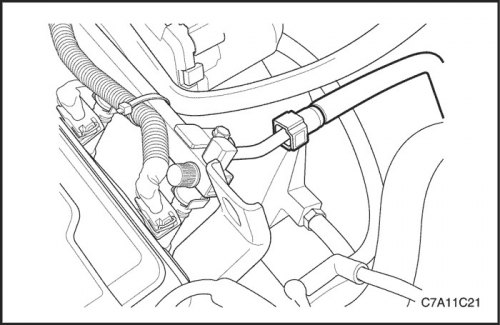

46. Disconnect the fuel supply line from the fuel rail.

47. Disconnect coolant hoses from rear cylinder head and EGR valve adapter (EGR).

48. Disconnect the coolant hoses from the electronic throttle body.

49. Remove the fuel rail assembly. See Section 1F2, Engine Controls - FAM II 2.4D.

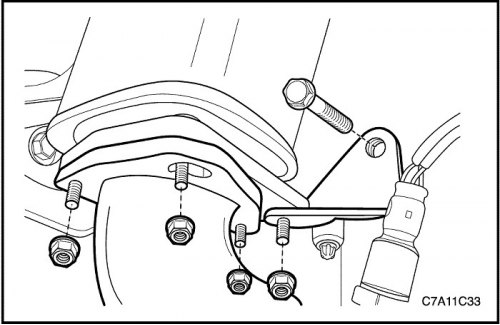

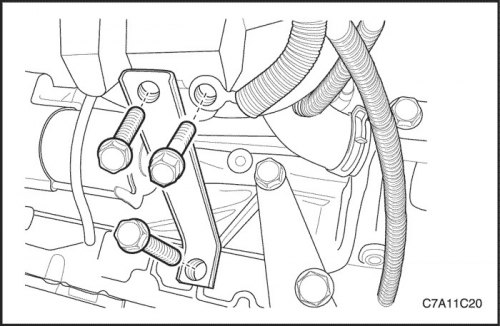

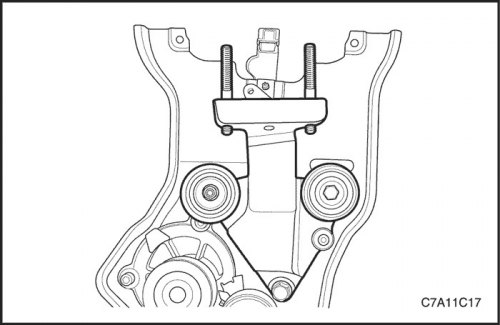

50. Loosen the alternator upper bracket bolts.

51. Remove the alternator top bracket.

52. Remove the alternator to intake manifold bracket bolts on the alternator and intake manifold.

53. Unscrew the bolt of the EVAP canister purge solenoid valve bracket.

54. Remove the EVAP canister purge valve.

55. Remove the camshaft. See «Camshaft» in this section.

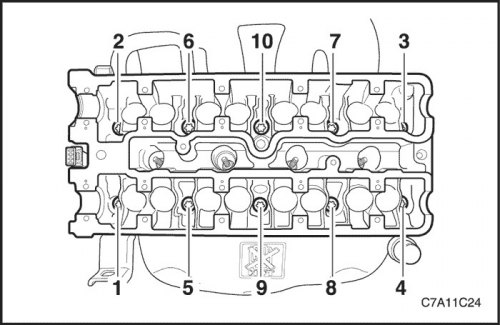

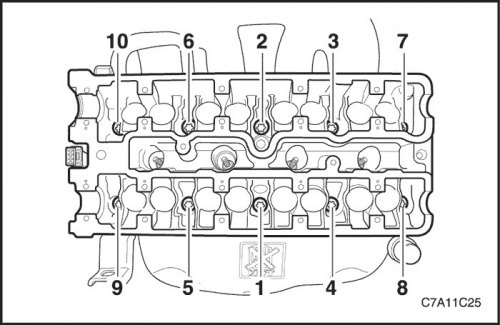

56. Loosen all cylinder head screws gradually and in the sequence shown.

57. Remove the cylinder head screws.

58. Remove the cylinder head with the intake and exhaust manifold attached.

Note: Do not allow engine oil or coolant to enter the cylinders when removing the cylinder head.

59. Remove the cylinder head gasket.

Cleaning procedure

1. Clean the surfaces of the cylinder head gasket and cylinder block.

2. Check that the cylinder head gasket and cylinder block surfaces are free of dents and deep scratches.

3. Clean the cylinder head screws.

4. Check the cylinder head for distortion. follow the paragraph «Cylinder head and valve train parts» in this section.

Installation procedure

Important: Before installing the cylinder head, be sure to install the engine mount and then remove the engine jig assembly DW110-060.

1. Install a new cylinder head gasket.

2. Install the cylinder head with the intake and exhaust manifolds attached.

3. Install the cylinder head bolts and gradually tighten them in the sequence shown.

Tighten

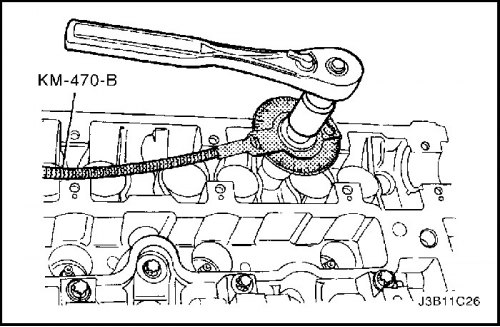

Tighten cylinder head bolts to 25 Nm (18 lb-ft) and turn the bolts an additional 3 turns of 90°using the angle torque indicator KM-470-B.

4. Install the camshaft. See «Camshaft» in this section.

5. Install the EVAP canister purge valve.

Tighten

Tighten the canister purge solenoid valve support bracket bolt to 5 Nm (44 lb-in.).

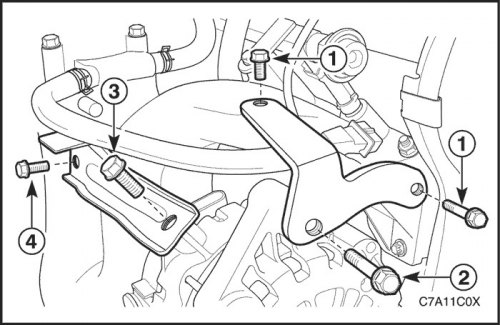

6. Install the alternator top bracket.

Tighten

Tighten the alternator upper bracket retaining bolts (1) torque 25 Nm (18 lb-ft), and the bolt (2) torque 35 Nm (26 lb-ft).

7. Install the alternator mounting bracket to the intake manifold.

Tighten

Tighten the retaining bolt for the alternator-to-inlet manifold bracket (3) torque 35 Н·м (26 lb-ft), and the bolt (4) torque 25 Н·м (18 lb-ft).

8. Connect the coolant hoses to the electronic throttle body, rear cylinder head and EGR valve bracket.

9. Install the fuel rail assembly. See Section 1F2, Engine Controls - FAM II 2.4D.

10. Connect the fuel supply line to the fuel rail.

11. Connect all necessary vacuum hoses.

12. Screw on the retaining bolt of the ground terminal.

13. Install the intake manifold support bracket.

Tighten

Tighten the intake manifold support bracket bolts to 25 Nm (18 lb-ft).

14. Install the exhaust pipe to the catalytic converter. See Section 1G2, Exhaust System - FAM II 2.4D.

Tighten

Tighten the lock nuts securing the catalytic converter to the exhaust pipe of the muffler to a torque of 35 Nm (26 lb-ft).

Tighten the bolt and nut of the muffler exhaust pipe mounting bracket to 40 Nm (30 lb-ft).

15. Install the timing belt rear cover.

Tighten

Tighten the timing belt rear cover bolts to 7 Nm (62 lb-in.).

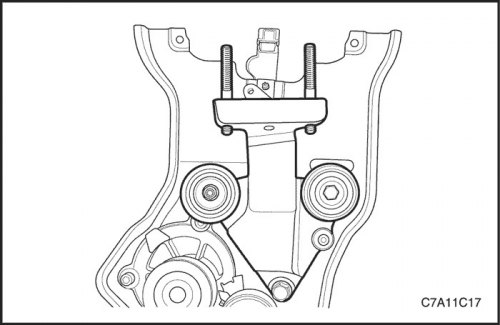

16. Install the engine mount adapter support bracket.

Tighten

Tighten the engine mount adapter support bracket retaining bolts to 45 Nm (33 lb-ft).

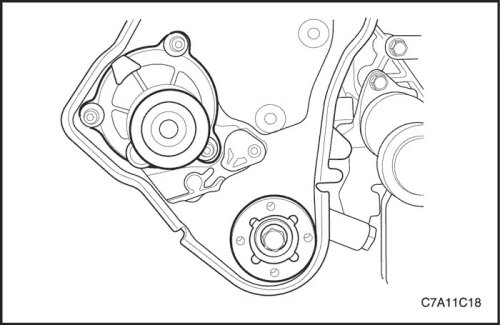

17. Install the timing belt idler pulleys.

Tighten

Tighten the locking bolt and nut of the timing belt idler pulley to 25 Nm (18 lb-ft).

18. Install the camshaft position sensor. See Section 1F2, Engine Controls - FAM II 2.4D.

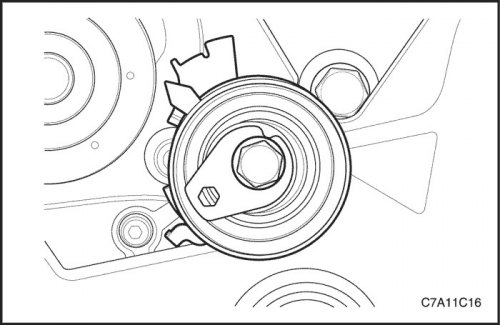

19. Install the crankshaft gear.

Tighten

Tighten the crankshaft timing belt drive gear bolt to 135 Nm (100 lb-ft) and turn the bolt another 30°and 10°using the angle torque indicator.

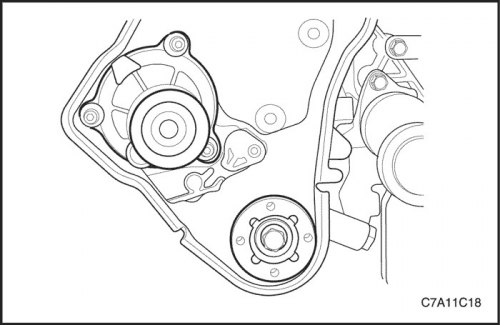

20. Install the automatic timing belt tensioner.

Tighten

Tighten the timing belt auto-tensioner retaining bolt to 25 Nm (18 lb-ft).

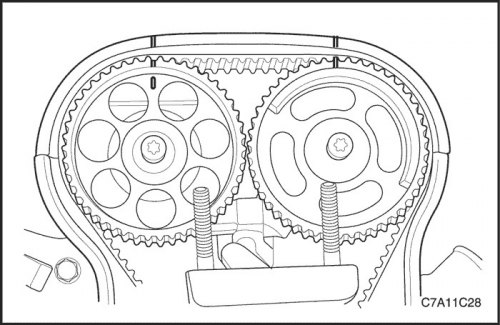

21. Install the camshaft gears with timing marks on the front.

22. Insert the guide pin of the intake camshaft into the hole "IN".

23. Insert the guide pin of the exhaust camshaft into the hole "EX".

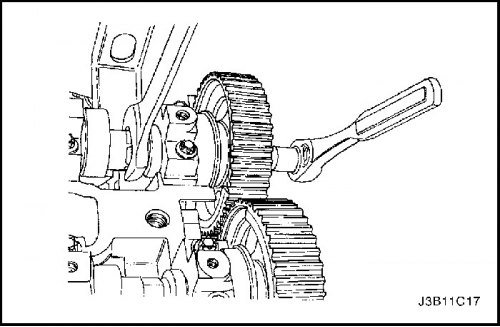

24. Install the camshaft gears while holding the camshaft hex head with an open end wrench.

25. While firmly holding the intake camshaft, install a new intake camshaft gear bolt.

Tighten

Tighten the intake camshaft gear bolt to 50 Nm (37 lb-ft) and turn it a further 60°and 15°with the angle torque indicator.

26. While firmly holding the exhaust camshaft, install a new exhaust camshaft gear bolt.

Tighten

Tighten the exhaust camshaft gear bolt to 50 Nm (37 lb-ft) and turn it another 60°and 15°with the angle torque indicator.

27. Apply a small amount of sealant to the corners of the front camshaft head and where the top of the rear cylinder head cover attaches to the cylinder head gasket.

28. Install the cylinder head cover gasket and cylinder head cover. See «Cylinder head cover and gasket» in this section.

Tighten

Tighten cylinder head cover bolts to 8 Nm (71 lb-in.).

29. Connect the ignition wires to the spark plugs.

30. Connect the breather hose and the positive crankcase ventilation hose to the cylinder head cover.

31. Align the timing marks on the camshaft gears with the notches on the cylinder head, using the intake gear mark for the intake gear and the exhaust gear mark for the exhaust gear.

32. Align the mark on the crankshaft gear with the notch on the bottom of the timing belt cover.

33. Install the timing belt.

34. Check and adjust the timing belt tension. Cm. "Checking and adjusting the tension of the timing belt"«Checking and adjusting the tension of the timing belt» in this section.

35. Install the timing belt front cover.

Tighten

Tighten the retaining bolts of the timing belt front cover to 6 Nm (53 lb-in.).

36. Install the crankshaft pulley.

Tighten

Tighten the crankshaft pulley bolts to 23 Nm (17 lb-ft).

37. Install the engine mount. See «Engine mount» in this section.

Tighten

Tighten the engine mount adapter bolts to 50 Nm (11 lb-ft).

Tighten the engine mount frame side bracket bolt to 100 Nm (74 lb-ft), and nuts with a torque of 90 Nm (66 lb-ft).

38. Remove engine jig assembly DW110-060.

39. Install the flex accessory drive belt. See «Accessory drive belt» in this section.

40. Connect the upper radiator hose to the thermostat housing.

41. Install the front engine shield on the right front wheel side.

42. Install the right front wheel. Follow Section 2E, Tires and wheels.

43. Install the air cleaner assembly. See «Air filter assembly» in this section.

Tighten

Tighten the air cleaner housing bolts to 10 Nm (89 lb-in.).

44. Connect the IAT sensor connector.

45. Connect the coolant temperature sensor connector (CTS).

46. Connect the electronic throttle control unit sensor connector (ETC).

47. Connect the DIS coil connector.

48. Connect the O2 sensor connector.

49. Connect the EGR valve connector (EGR).

50. Install the fuel pump fuse.

51. Connect the negative battery cable.

52. Refill the engine cooling system. See Section 1D2, Engine Cooling System - FAM II 2.4D.