Attention! Under no circumstances should spark plug gaps be adjusted. If the gap is not within specifications, replace the spark plug.

After checking the gap in the spark plugs, the presence of carbon deposits, the degree of wear of the electrodes or the integrity of the insulators, if necessary, replace them with new ones.

Remove and check the spark plugs as follows:

1. Remove the ignition wire end and disconnect the ignition wires from the spark plug. After disconnecting the ignition wires, you can disconnect the circuit. Therefore, you need to take only the part where there is a nozzle.

2. Remove the spark plugs from the cylinder head with a wrench.

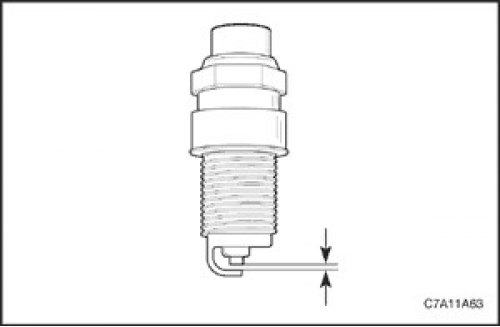

3. Measure spark plug gap with a gap gauge. If the measured value does not match the specified value, adjust the position of the ground electrode. During the installation of a new spark plug, it is necessary to check its quality and only then install it.

4. Inspect the spark plug as described below.

Spark Plug Deterioration

A spark plug may perform poorly due to wear, fouling, carbon deposits, severe electrode wear, a bad insulator, or excessive clearance.

Worn or dirty spark plugs

Worn or dirty spark plugs may work satisfactorily at idle, but may fail under load. This may cause:

- High fuel consumption

- power loss,

- loss of acceleration

- difficult start or

- reduction in engine power.

Soot formation

Nagar is a layer of black soot. Black soot is caused by driving at low speeds for short distances. Under such conditions, the optimum operating temperature of the engine is rarely reached. The formation of soot can also be due to:

- piston ring wear,

- ignition malfunction,

- enriched fuel mixture or too cold spark plugs.

Excessive electrode wear

Often this indicates the following:

- the engine is operated at high speeds,

- the engine is running at levels that are constantly above normal,

- Too hot spark plug

- too lean combustible mixture or overheating of the candle / candles due to insufficient tightening (gases released during combustion escape through the thread).

Damaged Insulator

Damaged insulators are usually the result of improper installation or negligence.

Upper insulator failure may be the result of a loose spark plug fit in the socket or an impact. An insulator crack cannot be detected until oil or moisture seeps through. Often the crack is below the curved portion of the spark plug body and is not visible.

Lower insulator failure is often the result of careless gap adjustments and can usually be detected.

It can also be the result of running a spark plug that is too hot. For example, operation at high speed or heavy load.

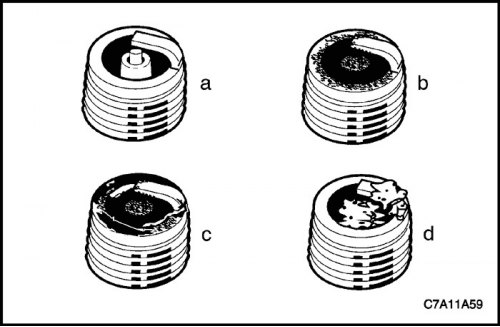

a - Normal state: Brown or gray carbon deposits and slight wear on the electrode indicate proper spark plug thermal performance and mixed low and high speed driving.

b - Covered in soot: Dry, loose black soot may be due to fuel with low ignition properties, a loose coil, excessive idling, or low speeds under light load. If the spark plug temperature is too low for normal combustion, the soot layer will not burn off.

c - oiled: A wet layer of oil with a slight wear of the electrode appears due to oil leakage through worn piston rings. Under such conditions, failure may occur in a new or recently overhauled engine before the rings are completely broken in.

d - Nagar A: Red-brown, yellow and white coating on the skirt of the spark plug insulator, which is a by-product of combustion. Plaque comes from fuel and lubricants, which usually contain additives. Most powdered deposits do not adversely affect spark plug performance, although they can cause temporary failure under various operating conditions.

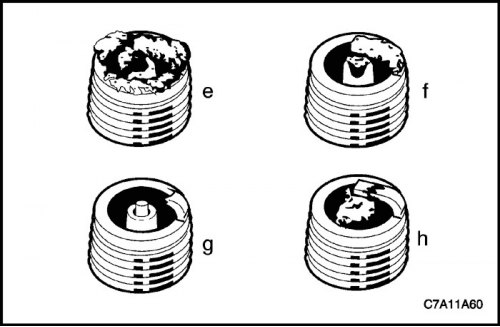

e - Nagar B: soot similar to the described soot A (4). It is also a by-product of the combustion of fuels and lubricants. Excessive valve stem clearances and/or damaged intake valve seals allow too much oil into the combustion chamber inlet. Carbon accumulates on part of the spark plug, enters the chamber and is deposited on the side of the intake valve. Under these conditions, it can only be found in one or two cylinders, the valve stem seals should be checked.

f - Nagar C: Most of the powdered deposits described under A deposits (4), does not adversely affect spark plug performance as long as they remain in a powdered state. Under certain conditions of action, these deposits are heated and form a shiny glaze layer on the insulator. At high temperatures, it acts as a good conductor, passing current through the deposit instead of sparking through the gap.

g - Detonation: Usually associated with engine knocking or engine knocking, knocking causes strong shocks inside the combustion chamber, which can lead to structural damage.

h - Preignition: Burnt or porous insulator skirt and very badly eroded electrodes, probably due to excessive heat. This is often due to a clogged cooling system, stuck valves, improperly installed spark plugs, or plugs that have the wrong glow rating (too high). Prolonged operation at high speed under heavy load can result in temperatures so high that pre-ignition occurs.

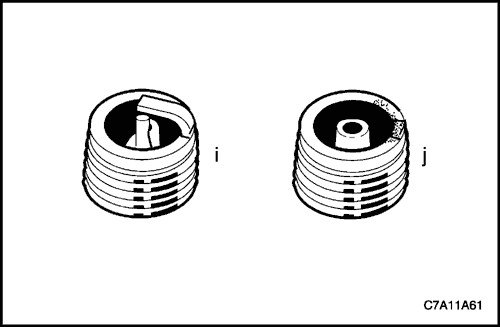

i - Malfunction due to thermal shock: A rapid rise in spark plug skirt temperature under certain operating conditions can cause thermal shock and crack the insulator. This is a common cause of breakage and cracking of the insulator skirt.

j - Insufficient set torque: Poor contact between spark plug and cylinder head seat. Due to poor contact with the seat, proper heat exchange does not occur, which causes the spark plug to overheat. Very often there are various injuries. Dirt on the threads in the cylinder head can cause a spark plug that has not yet been burnt in to stick. Before installing, make sure that there are no deposits, scuffs and scale on the cylinder head and spark plug threads.