Removal procedure

1. Disconnect the negative battery cable.

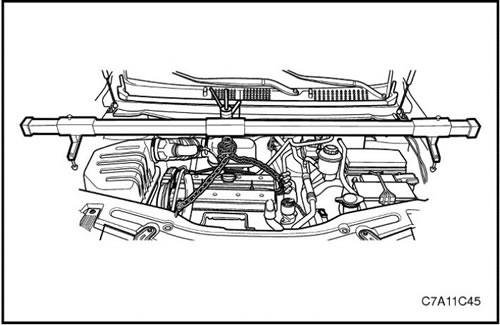

2. Remove decorative cover. See «Decorative cover» in this section.

3. Remove the hoses and ducts of the charge air system. See «Air injection system» in this section.

4. Remove the accessory belt. See «Accessory drive belt and tensioner» in this section.

5. Remove damping engine mount block. See «Engine Mount Assembly (Right side)» in this section.

6. Drain the engine oil.

7. Remove the timing belt. See «Timing Belt System» in this section.

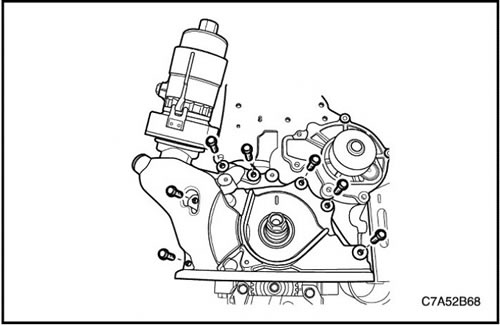

8. Remove the oil pump. See «Oil pump» in this section.

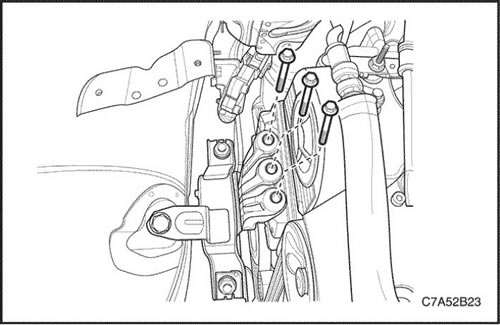

9. Loosen the base plate-to-transaxle bolt.

10. Loosen the engine block ground bolt.

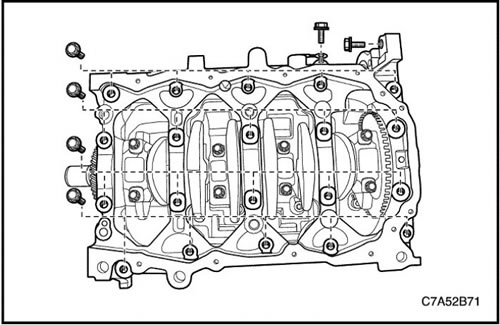

11. Remove the engine base plate.

Cleaning procedure

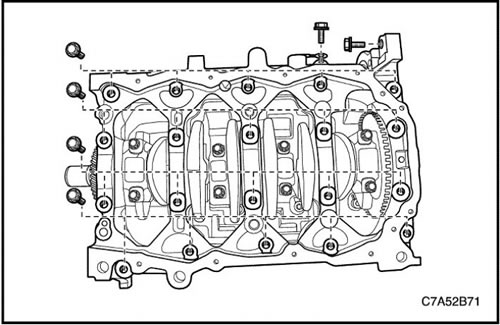

1. Clean the sealing surface of the base plate.

2. Clean the sealing surface of the cylinder block.

3. Clean the base plate pinch bolts.

4. Clean the bolt holes of the base plate.

Installation procedure

Important: When changing the engine oil, reset the engine oil service before changing using the scan tool.

1. Apply sealant (Hylomar 3000) on the sealing surface of the base plate.

2. Install the base plate.

3. Install the engine block ground bolt.

4. Install the base plate-to-transaxle bolt.

Tighten

Tighten base plate internal bolts to 25 Nm (18.4 lb-ft). Using the KM-470-B angle torque indicator, tighten the base plate inner bolts an additional 45 degrees plus 90 degrees.

Tighten base plate outer bolts to 35 Nm (25.8 lb-ft).

Tighten the engine block ground bolt to 25 Nm (18.4 lb-ft).

Tighten the transaxle pinch bolt (bolt of fastening of a basic plate to a transmission with the final drive assy) up to 75 Nm (55.3 lb-ft).