Necessary equipment

EN-48250 Crankshaft Front Oil Seal Installer

Removal procedure

1. Disconnect the negative battery cable.

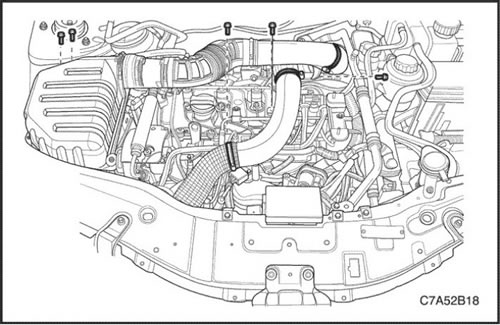

2. Remove decorative cover. See «Decorative cover» in this section.

3. Remove the hoses and ducts of the charge air system. See «Air injection system» in this section.

4. Remove the accessory belt. See «Accessory drive belt and tensioner» in this section.

5. Remove damping engine mount block. See «Engine Mount Assembly (Right side)» in this section.

6. Drain the engine oil.

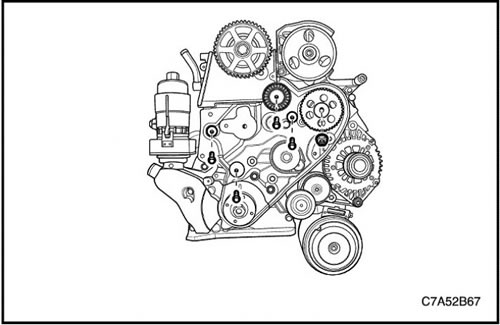

7. Remove the timing belt. See «Timing Belt System» in this section.

8. Remove the timing belt tensioner pulley.

9. Remove injection pump sprocket.

10. Remove the timing belt rear cover.

11. Remove crankshaft sprocket.

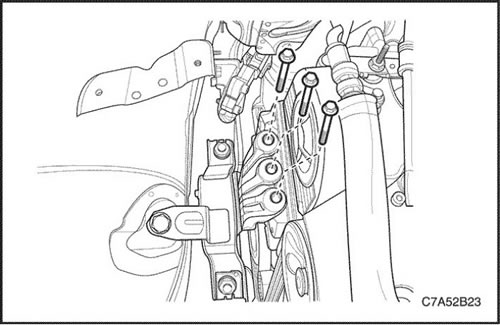

12. Disconnect the engine oil pressure sensor connector.

13. Disconnect the engine cooling oil cooler inlet/outlet hoses. See «Engine oil filter and radiator» in this section.

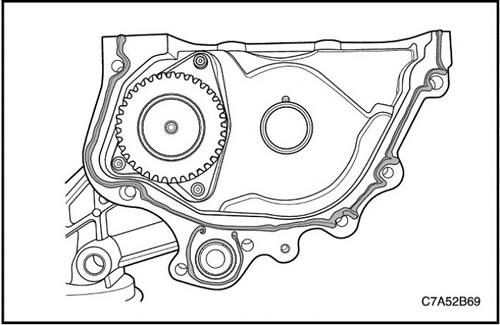

14. Remove the engine oil pump assembly.

Cleaning procedure

1. Clean the sealing surface of the oil pump.

2. Clean the sealing surface of the cylinder block.

3. Clean the oil pump pinch bolts.

4. Clean the oil pump bolt holes.

Installation procedure

Important: When changing the engine oil, reset the engine oil service before changing using the scan tool.

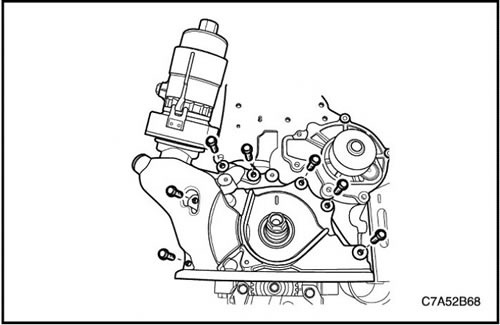

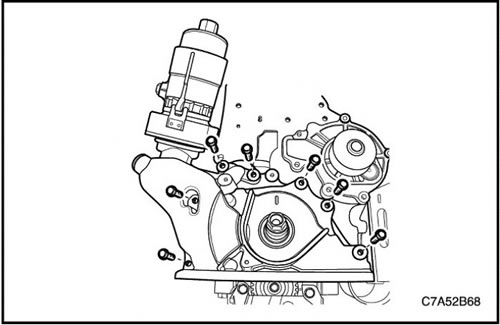

1. Apply sealant (LOCTITE 5900) on the sealing surface of the oil pump.

2. Install the oil pump assembly with a new oil pump seal.

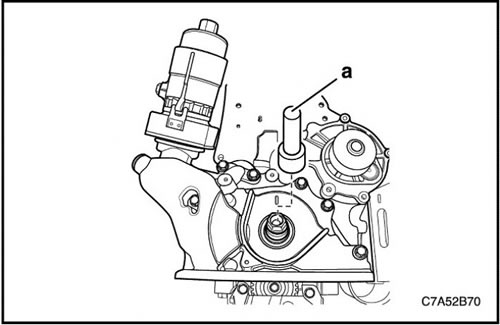

3. Install the front crankshaft oil seal using the EN-48250 front crankshaft oil seal installer (a).

Note: If damaged, the front crankshaft oil seal must be replaced with a new one. When installing the crankshaft front oil seal on the oil pump, make sure that the oil seal groove faces the contact direction of the oil pump housing.

Tighten

Tighten the oil pump pinch bolts to 24 Nm (17.7 lb-ft).

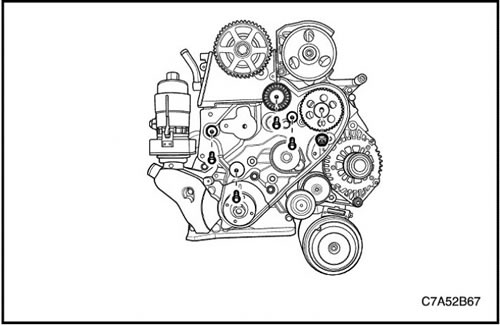

4. Install the rear timing belt cover.

5. Install injection pump sprocket.

6. Install the timing belt tensioner.

Tighten

Tighten the timing belt rear cover bolts to 11 Nm (97.4 lb-in).

Tighten the injection pump sprocket nut to 70 Nm (51.6 lb-in).

Tighten the locking bolt of the timing belt tensioner pulley to 52 Nm (38.4 lb-in).

7. Install the crankshaft sprocket.

Tighten

Tighten the crankshaft sprocket nut to 235 Nm (173.3 lb-ft).