Removal procedure

1. Disconnect the negative battery cable.

2. Remove decorative cover. See «Decorative cover» in this section.

3. Remove the hoses and ducts of the charge air system. See «Air injection system» in this section.

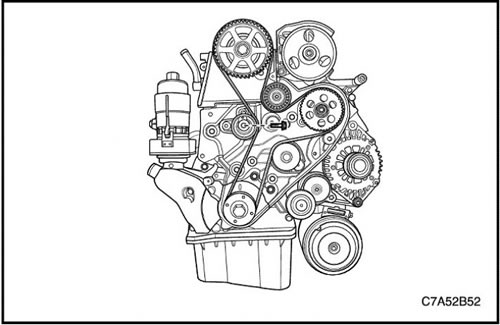

4. Remove the accessory belt. See «Accessory drive belt and tensioner» in this section.

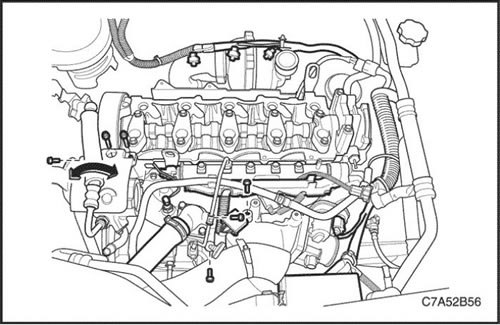

5. Remove cylinder head cover. See «cylinder head cover» in this section.

6. Remove the timing belt. See «Timing Belt System» in this section.

7. Remove the fuel line to the common rail located between the common rail and the fuel injection pump. See Part 1F1, Engine Controls - 2.0 Diesel.

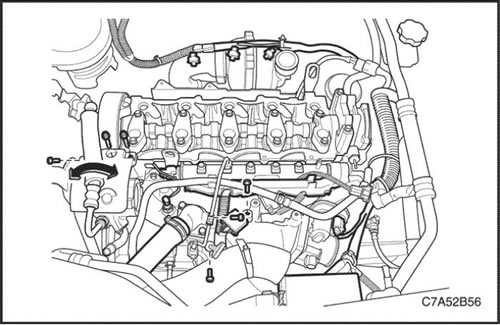

8. Remove power steering pump retainer and swivel to left side.

9. Unscrew the coupling bolt of the motor wiring terminal block.

10. Remove the oil level gauge tube.

11. Remove the upper radiator hose from the thermostat housing.

12. Remove the engine wiring connectors.

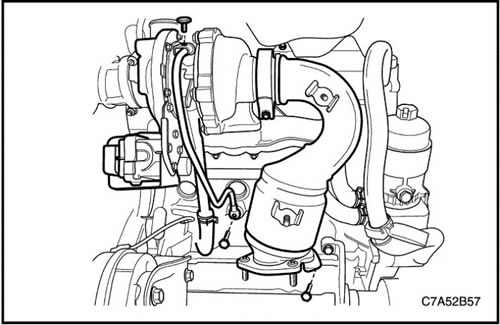

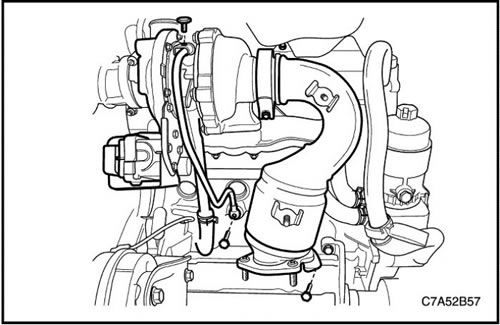

13. Remove the oil supply pipe to the turbocharger impeller bearing.

14. Remove the oil outlet hose from the turbocharger impeller bearing.

15. Remove the pre-catalytic converter clamp from the turbocharger.

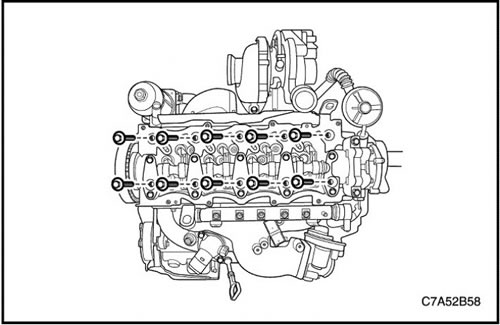

16. Remove the cylinder head screws.

17. Remove the cylinder head assembly with gasket.

18. Remove the intake manifold and exhaust manifold from the cylinder head assembly. See «Intake manifold" And "An exhaust manifold» in this section.

Cleaning procedure

1. Clean the surface of the cylinder head.

2. Clean the surface of the engine block.

3. Clean the cylinder head screws.

4. Clean the engine block bolt holes.

Choose gasket

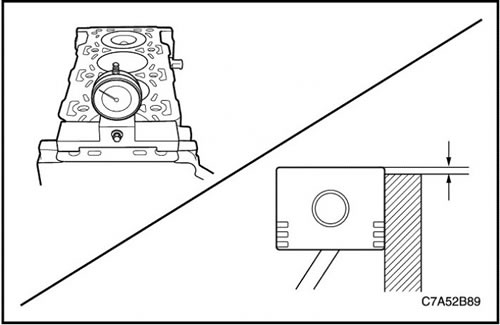

1. Set the piston to TDC.

2. Clean the sealing surface of the cylinder head and piston.

3. Measure piston protrusion with a dial indicator.

4. Repeat this measurement on the other cylinders and calculate the arithmetic mean of the piston protrusion from the measurement results.

5. Select a cylinder head gasket according to the specifications below.

| Piston protrusion, mm | Gasket thickness, mm |

| 0,194...0,337 | 1.1 |

| 0,337...0,440 | 1,2 |

| 0,440...0,542 | 1.3 |

Installation procedure

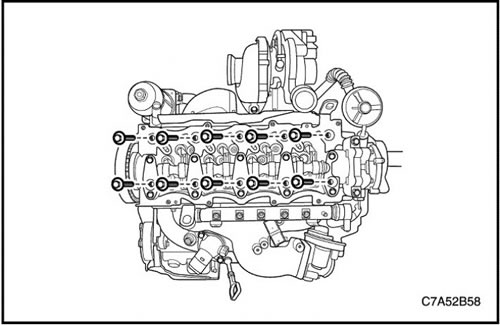

1. Install the cylinder head assembly with a new gasket.

2. Tighten the cylinder head pinch bolts.

Tighten

Tighten cylinder head bolts to 65 Nm (47.9 lb-ft). Using the angle torque gauge KM-470-B, tighten the cylinder head bolts an additional 120 degrees plus 120 degrees.

3. Install the pre-catalytic converter clamp to the turbocharger.

4. Install the oil supply pipe to the turbocharger impeller bearing.

Tighten

Tighten the bolts of the oil feed pipe to the impeller bearing of the turbocharger to 23 Nm (17 lb-ft).

5. Screw in the coupling bolt of the motor wiring terminal block.

6. Install the power steering pump bracket.

7. Install the fuel line to the common rail located between the common rail and the fuel injection pump.

8. Install the oil level gauge tube.

Tighten

Tighten the pinch bolt of the engine wiring harness terminal block to 15 Nm (11.1 lb-ft).

Tighten the steering pump bolts to 25 Nm (18.4 lb-ft).

Tighten the nut securing the fuel line to the common fuel rail to 20 Nm (14.8 lb-ft).

Tighten the bolt securing the fuel line to the common fuel rail to 10 Nm (88.5 lb-in).

Tighten the oil level indicator tube bolts to 11 Nm (97.4 lb-in).