Necessary equipment

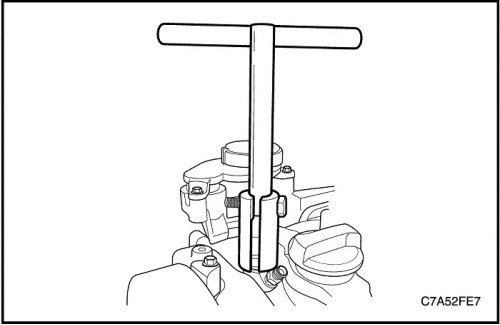

EN-48357 Nozzle puller

Attention! Do not smoke or use open flames in areas where work is being done on the fuel system. When working on the fuel system, disconnect the negative battery cable, except for tests that require battery voltage.

Removal procedure

1. Disconnect the negative battery cable.

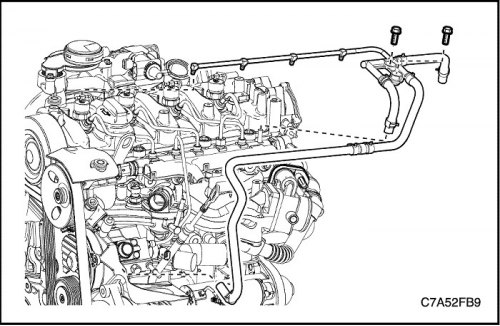

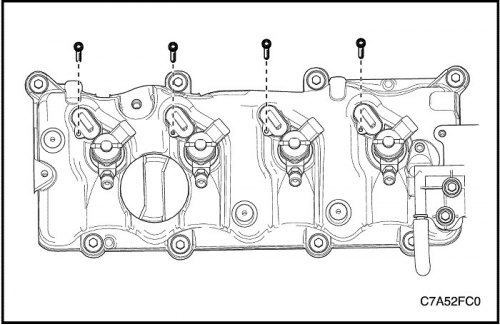

2. Remove the high pressure fuel lines. See «High pressure fuel supply lines» in this section.

3. Remove injector return hoses. See «Return fuel line assy» in this section.

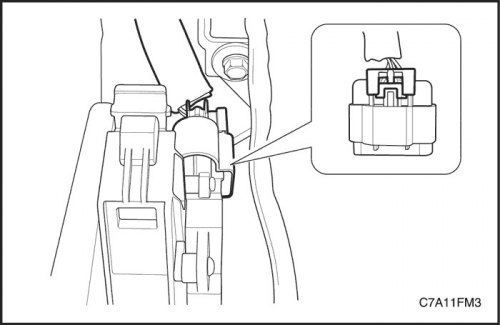

4. Disconnect the injector connector.

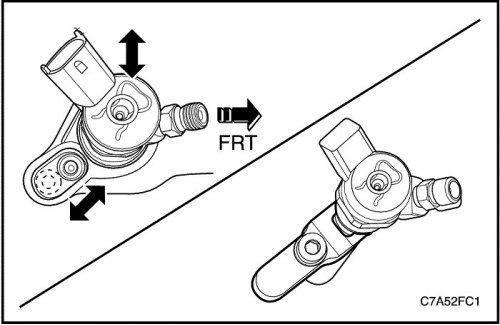

5. Remove the injector bracket plug.

6. Loosen the injector bracket bolt.

7. Pull the injector bracket by hand using the bolt.

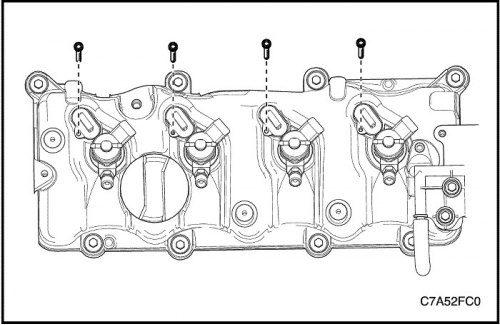

8. Remove injectors with washers up.

Attention! Sequentially number the nozzles with a pencil. If you mix up the serial number of the injector, this will affect the performance of the engine.

Attention! Protect the nozzle tip from the floor and hard areas. If possible, put a cap on the nozzle tip of the nozzle.

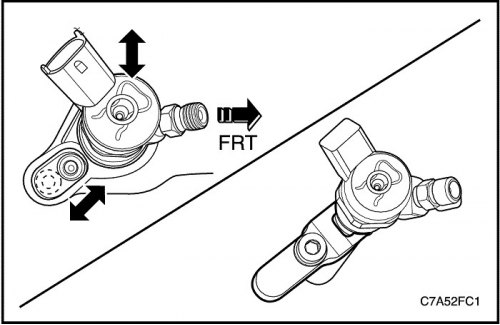

9. If the injector is stuck to the cylinder head, use the EN-48357 injector puller.

Installation procedure

Attention! The nozzle washer cannot be reused.

1. Inspect and clean the nozzle and nozzle tip.

Attention! Do not wipe the nozzle tip area. This may damage the nozzle opening.

2. Install the injector with a new washer.

3. Insert the injector bracket into the injector groove.

4. Tighten the injector bracket bolt.

Tighten

Tighten the injector bracket bolt to 28 Nm (20.7 lb-ft).

5. Install the injector bracket plug.

Tighten

Tighten the injector bracket plug bolt to 7 Nm (62.0 lb-in).

Important: Fuel lines must not be reused. When reused, contaminated tubes can damage nozzles or leak tubes.

6. Perform fuel bleeding. See «Fuel pumping» in this section.

Important: When replacing an injector or changing the order of the injector sequence, reprogram and reset the EEPROM values for ZFC (Zero fuel trim) injectors using the diagnostic tool.