Attention! Do not smoke or use open flames in areas where work is being done on the fuel system. When working on the fuel system, disconnect the negative battery cable, except for tests that require battery voltage.

Removal procedure

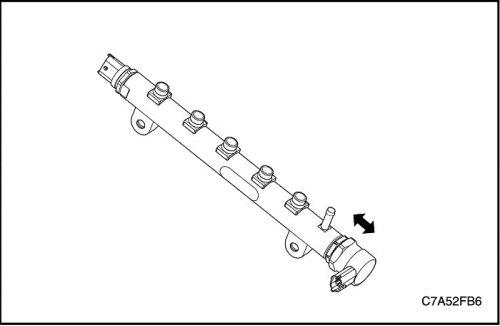

1. Remove the common fuel rail assembly. See «Common rail» in this section.

2. Clean the ramp adjuster interface with suitable degreasers and dry with compressed air.

Note: Cleaning agents must not get into the electrical connector.

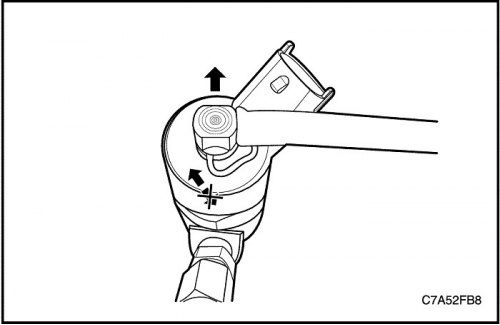

3. Loosen the component with a WAF30 industrial wrench, grasp it with your hand and pull it out while turning it counterclockwise.

Installation procedure

Important: This common rail regulator and O-ring cannot be reused.

Attention! Do not blow air from the spray gun inside the injector sleeves, the injection pump and the threaded connections of the pipes of the common fuel rail. In case of contamination, wipe the dusty area with oiled paper.

Attention! Do not wipe with napkins inside the injector couplings, injection pump and threaded connections of the pipes of the common fuel rail. In case of contamination, wipe the dusty area with oiled paper.

1. Inspect and clean the threads and sealing surface of the rail.

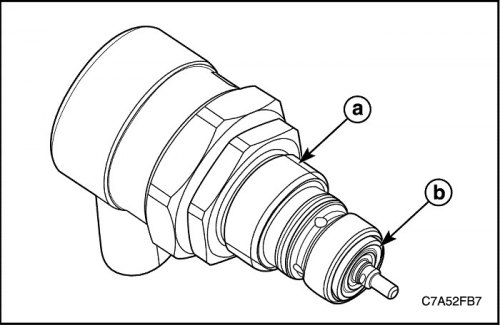

2. Inspect and clean the thread (a) and cutting edge (b) common rail regulator.

Note: Inspect the sealing surfaces of the DRV and rail or high pressure pump. Only concentric grooves are allowed. Any cuts in the radial direction are not allowed. Inspect Torx or shoulder screws for any damage.

3. Lubricate the O-rings with fuel.

4. Install the common rail regulator with a WAF30 industrial wrench while holding the hexagonal part of the body against reverse rotation with the WAF35 wrench.

Tighten

Tighten the common rail regulator to 60 Nm (44.3 lb-ft), turn the adjuster 90 degrees in the opposite direction and tighten to 85 Nm (62.7 lb-ft).

5. Perform fuel bleeding. See «Fuel pumping» in this section.