Removal procedure

Attention! Do not smoke or use open flames in areas where work is being done on the fuel system. When working on the fuel system, disconnect the negative battery cable, except for tests that require battery voltage.

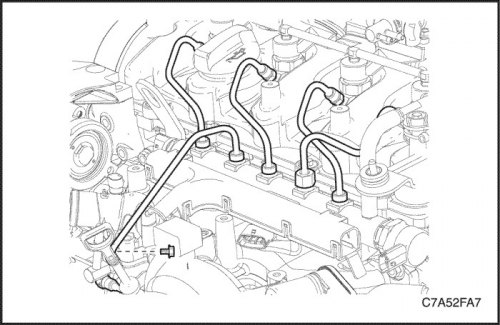

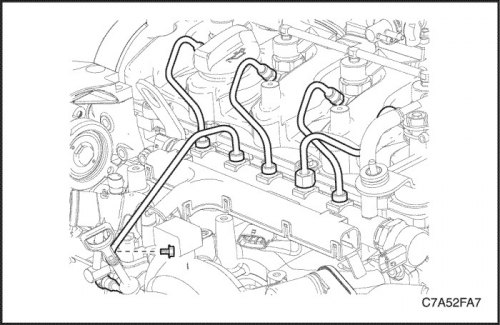

1. Remove decorative cover. See Section 1B, "Engine mechanical system - 2.0 Diesel".

2. Remove the air intake system. See Section 1B, "Engine mechanical system - 2.0 Diesel".

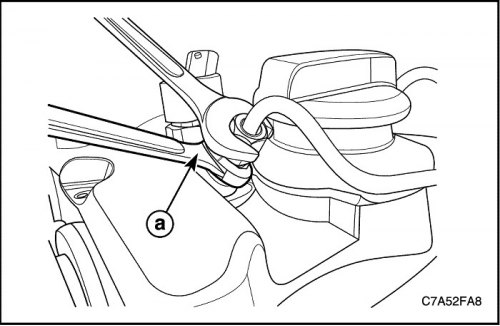

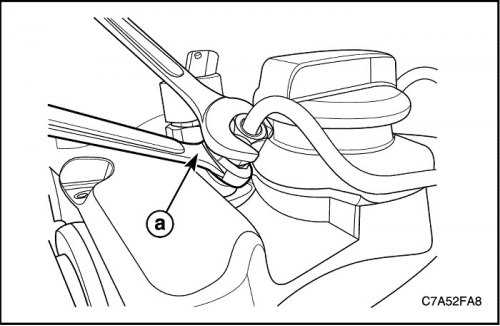

3. Holding the injector slip (a), unscrew the nut (M14) attaching the fuel line to the injector.

Attention! To avoid fuel spillage or damage from the injector shifter, hold the injector shifter with tools and loosen the tube nut. And then, immediately after removing the fuel lines, put a cap on the injector connector to avoid dust contamination. Even small amounts of dust can clog nozzles.

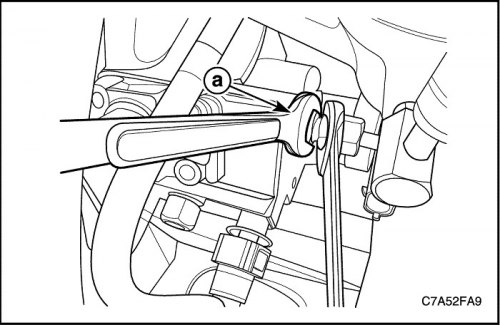

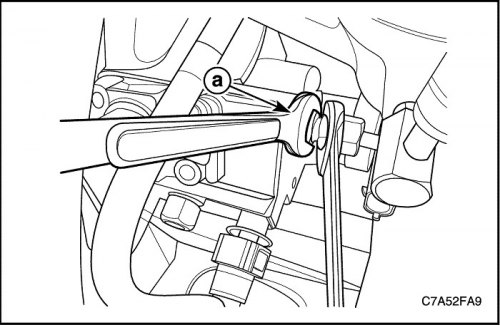

4. Holding the injection pump slip (a), unscrew the nut (M14) fastening the fuel line to a common fuel rail.

Attention! To prevent spillage of fuel or damage from the injection pump clutch, hold the injection pump clutch with tools and loosen the nut (M14) fastening the fuel line to a common fuel rail. And then, immediately after removing the fuel lines, put a cap on the injection pipe connector to prevent dust contamination. Even small amounts of dust can clog nozzles.

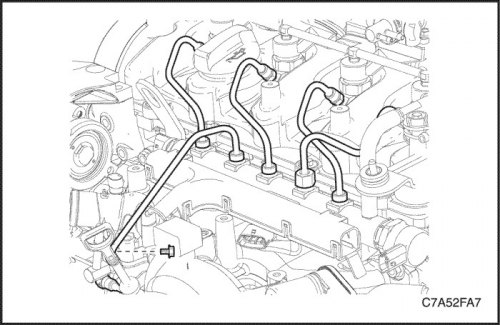

5. Unscrew the nut securing the fuel line to the common fuel rail (M17).

6. Unscrew the bolt securing the fuel line to the common fuel rail from the thermostat housing.

7. Remove the pipe from the fuel line to the common fuel rail and the pipes from the fuel line to the injectors.

Attention! Immediately after removing the threaded connections, put caps on the threaded connections of the pipes of the common rail to prevent dust contamination. Even small amounts of dust can clog nozzles.

Installation procedure

Important: Fuel lines must not be reused. When reused, contaminated tubes can damage nozzles or leak tubes.

Attention! Fuel lines must not be reused. When reused, contaminated tubes can damage nozzles or leak tubes.

Attention! Do not wipe with napkins inside the injector couplings, injection pump and threaded connections of the pipes of the common fuel rail. In case of contamination, wipe the dusty area with oiled paper.

1. If the threaded connection of the common rail pipe is dirty, clean it with oiled paper.

2. Loosen the injector bracket bolts. See «Nozzle» in this section.

3. Install the fuel lines between the injectors and the common rail and hand tighten the nuts.

Attention! Do not tighten fuel line nuts with a tool.

4. Tighten the injector bracket bolts.

Tighten

Tighten the injector bracket bolt to 28 Nm (20.7 lb-ft).

5. Holding the injector slip (a), tighten the nut (M14) attaching the fuel line to the injector.

Tighten

Tighten the nut (M14) fixing the fuel line to the injector up to 27 Nm (19.9 lb-ft).

6. Tighten the nut (M17) attaching the fuel line to the injector.

Tighten

Tighten the nut (M17) fixing the fuel line to the injector up to 20 Nm (14.8 lb-ft).

7. Install the fuel line between the common rail and the injection pump and hand tighten the nuts.

Attention! Do not tighten fuel line nuts with a tool.

8. Holding the injection pump slip (a), tighten the nut (M14) fastening the fuel line to a common fuel rail.

Tighten

Tighten the nut (M14) fixing the fuel line to a common fuel rail up to 20 Nm (14.8 lb-ft).

9. Tighten the nut (M17) fastening the fuel line to a common fuel rail.

Tighten

Tighten the nut (M17) fixing the fuel line to a common fuel rail up to 20 Nm (14.8 lb-ft).