Cylinder head

This cylinder head is SOHC type (with single overhead camshaft) and has only one camshaft that opens 4 valves per cylinder using roller-type tappets and valve bridges. It looks like a DOHC cylinder head (with double overhead camshaft).

The camshaft gear is mounted in front of the camshaft and the vacuum pump is attached to the rear of the camshaft. Since the tappet is hydraulic type, there is no need to adjust the valve clearance.

The cylinder head is cast aluminum alloy for increased strength combined with light weight.

The cylinder head's vane-type combustion chamber is designed to improve swirl and compression efficiency at the end of the compression stroke to maximize diesel combustion efficiency.

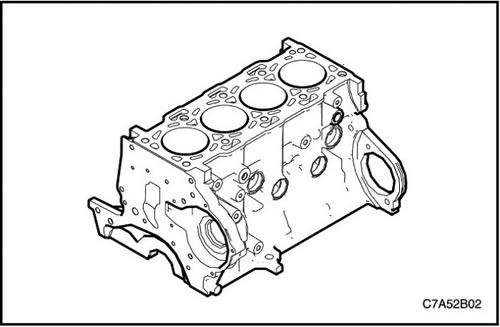

Cylinder block

The engine block, as the largest part of the engine components, is made of cast iron. The inside of the engine block contains passages for engine oil and coolant for lubrication and cooling. On the top side of the engine block is the cylinder head, which houses the combustion chamber. Also, the engine block has a base plate on the underside to support the crankshaft and reduce engine vibration.

On the inner surface of the engine block there are boring hole surfaces in which reciprocating pistons are arranged, and 4 jet lubrication nozzles on each surface of the boring hole.

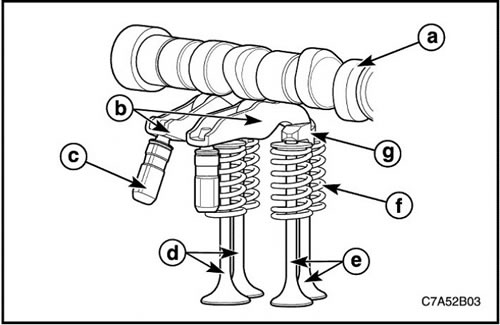

Valve mechanism

The engine uses a valve follower pin and hydraulic clearance adjustment to actuate the valve.

In the middle of the valve follower pin there is a roller that continuously transmits the movement of the cam to the valve bridge in accordance with the profile of the cam.

|

Designation

|

Name

|

PURPOSE

|

|

a

|

Camshaft

|

Drives valve system

|

|

b

|

Valve pusher

|

Transmits rotation to the valve bridge

|

|

c

|

Hydraulic valve clearance compensator

|

Rotates and compensates by activating and deactivating movement

|

|

d

|

Inlet valve

|

Creates fresh gas flow

|

|

e

|

Exhaust valve

|

Generates exhaust gas flow

|

|

f

|

valve spring

|

Holds the valve in the closed position

|

|

G

|

valve bridge

|

Activates the movement of two valves

|

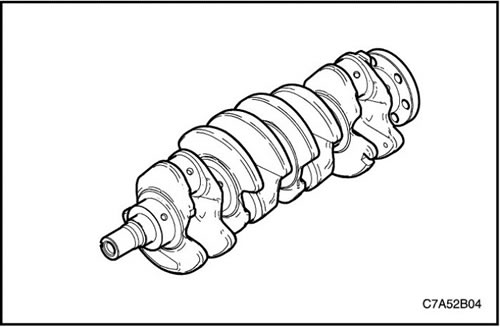

Crankshaft

The crankshaft uses a forged construction that provides greater tensile strength than cast iron. It is located between the engine block and the base plate on 5 main journals with main bearings, which have an oil clearance for lubrication. The 3rd of the 5 main bearings is the thrust bearing, which ensures that the crankshaft has the correct axial clearance.

The crankshaft is assembled from 4 connecting rod journals with metal bearing shells, the covers of which are bolted transversely to increase structural rigidity.

On the front side of the crankshaft is the crankshaft gear, which drives the oil pump and crankshaft balancer. On the back of the crankshaft is a wheel with "target" to send a signal to the CPS (crankshaft position sensor).

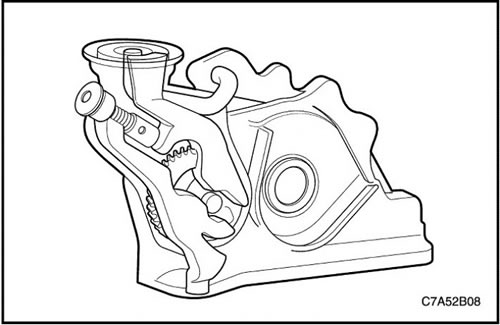

The balancer of a cranked shaft assy

The crankshaft gear drives 2 balancer shafts that rotate in opposite directions. Thus, the balancer balances the vibration from the crank mechanism. It is located between the base plate and the oil pan with engine oil.

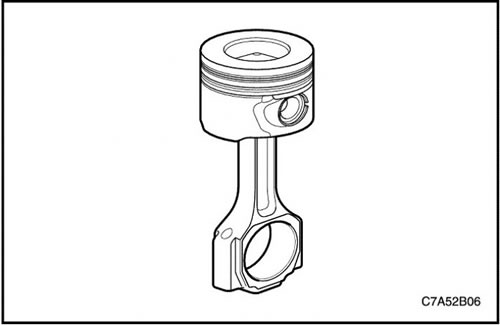

Piston, connecting rod assy

The pistons are cast aluminum with a combustion chamber in the bottom. They have 2 compression rings and 1 oil scraper ring assembly with a spring. Between the piston pin hole and the connecting rod pin hole is a fully floating type piston pin, which is secured with a retainer at both ends.

The connecting rod and big end cap with bearings are installed in place and secured with bolts.

Positive crankcase ventilation valve (PCV)

The PCV valve transfers blow-by gases to the intake port of the intake system turbocharger. Depending on the condition of the engine, driving conditions and turbocharger pressure, the amount of crankcase gases changes. Thus, the PCV valve regulates the amount of crankcase gases.

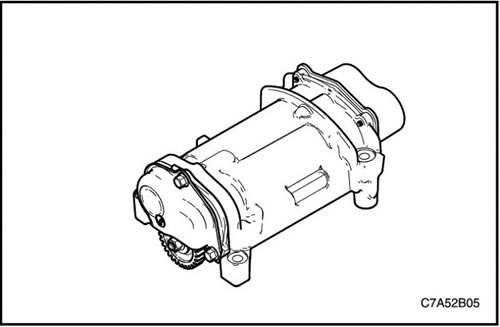

Oil pump

The oil pump draws engine oil from the oil pan and supplies it under pressure to various parts of the engine. An oil filter is installed upstream of the oil pump inlet to remove contaminants that could clog or damage the oil pump or other engine components. When the crankshaft rotates, the driven gear of the oil pump rotates. This causes the gap between the gears to constantly narrow and open, sucking oil from the oil pan when the gap opens and pumping oil into the engine when it narrows.

At high engine speeds, the oil pump delivers much more oil than is needed to lubricate the engine.

The oil pressure regulator prevents excess oil from entering the engine lubrication channels. With normal oil supply, the coil spring and valve hold the bypass closed, directing all of the oil to the engine. As the volume of oil pumped increases, the pressure rises to a level sufficient to overcome the spring force.

This opens the oil pressure control valve, allowing oil to flow through the valve and drain back into the oil pan.

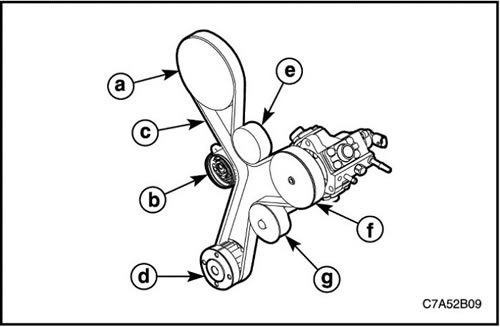

Gas distribution system

The crankshaft pulley assembly drives the camshaft sprocket, water pump pulley and high pressure pump sprocket with the timing belt. Also, the tension of the timing belt is assisted by a double eccentric type automatic tensioner.

The timing belt idler pulley, which uses a double-row type bearing to withstand heavy loads, increases the wrap angle between the camshaft sprocket and the high pressure pump sprocket to increase power output.

|

Designation

|

Name

|

PURPOSE

|

|

a

|

Camshaft sprocket

|

Drives the camshaft.

|

|

b

|

Tensioner of the drive belt of the gas distribution mechanism

|

Adjusts the tension of the timing belt.

|

|

c

|

The drive belt of the gas distribution mechanism

|

Transfers power to the pulley and sprocket.

|

|

d

|

crankshaft sprocket

|

Transfers power from the crankshaft.

|

|

e

|

Timing belt idler pulley

|

Increases grip angles.

|

|

f

|

High pressure pump sprocket

|

Drives a high pressure pump.

|

|

G

|

Water pump pulley

|

Drives a water pump.

|

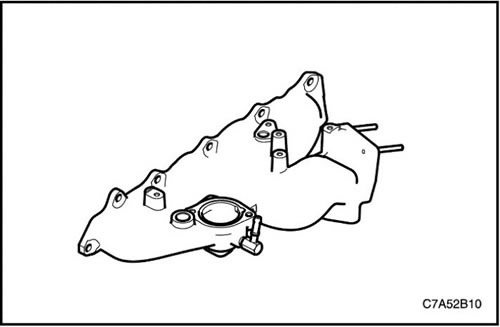

Intake manifold

The intake manifold is a channel for air flow into the combustion chamber of the cylinder through the throttle body and affects engine torque, power, noise, vehicle handling, emissions, fuel economy and performance.

It is made from die-cast aluminum alloy for increased strength combined with light weight and is integral with the coolant passage.

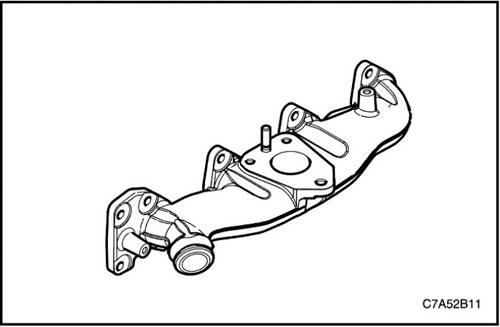

An exhaust manifold

The exhaust manifold is placed on the cylinder head and sends exhaust gases from the combustion chamber to the turbocharger. It is designed to withstand high pressure and high temperature and is made of HiSiMo material.

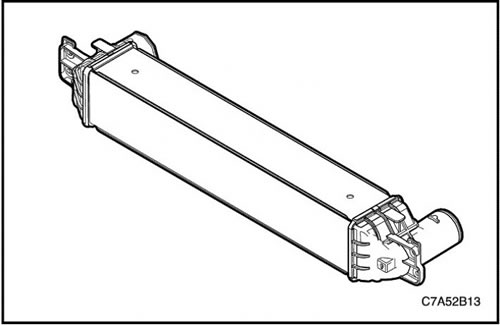

Charge air cooler

A turbocharger is a device that supplies hot and compressed air, i.e. from a turbine, by sucking in exhaust gases or ram air, to an engine to increase power.

The rapidly compressed air from this turbocharger expands at high temperature and causes a decrease in the efficiency of charge into the cylinder as the oxygen concentration decreases.

However, the efficiency of the charge into the cylinder increases as the compressed hot air cools and the density of the air increases as it passes through the charge air cooler.

It also improves fuel efficiency and reduces CO2 emissions.

Mounted on top of the radiator at the front of the vehicle, the charge air cooler cools compressed hot air by directing airflow through the grille.

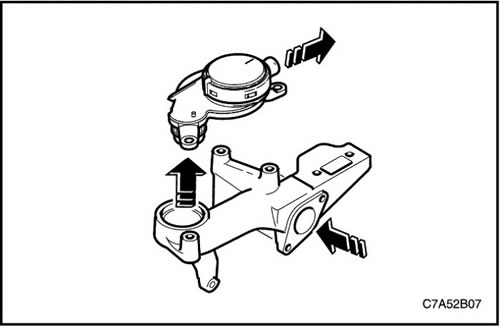

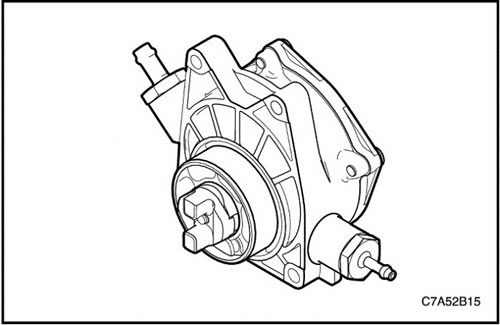

Vacuum pump

Vacuum pump provides vacuum for brake booster and EGR controller (EGR) on a diesel engine and is mounted on the upper left side of the engine to mate with the camshaft and is driven from the camshaft on a Euro 4 diesel engine.

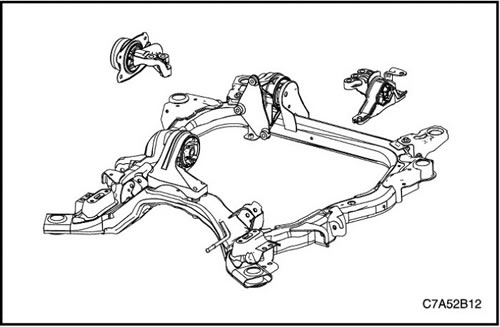

Suspension

The engine suspension system serves to mount the power plant on the body and support the power plant in its design stationary position. Suspensions are designed to reduce dynamic loads, both internally generated by the power plant and external road influences, by isolating the vehicle from the power plant, controlling the movement of the power plant, and counteracting the forces and torques of the power plant.

The engine suspension system includes four suspensions: Left and right load-bearing support suspensions and front and rear anti-torque suspensions.

Right suspension (engine) is a normal suspension, while the left (gearboxes) is a hydraulic suspension. Both front and rear suspensions are standard.