Disassembly procedure

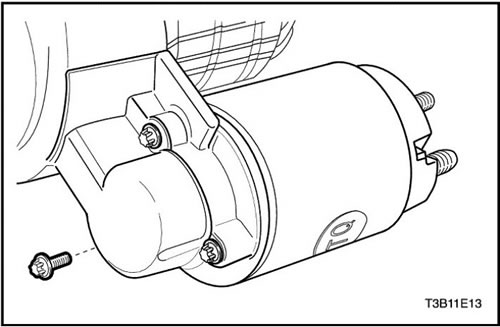

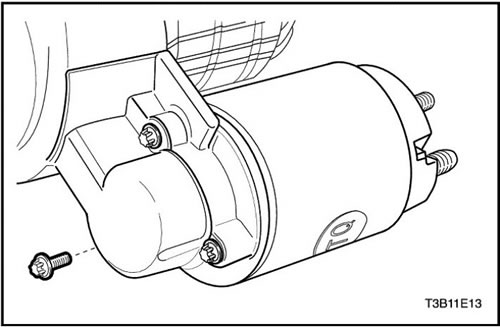

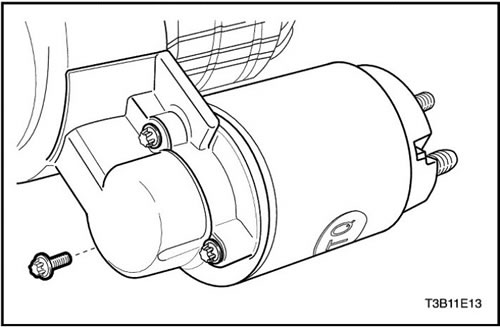

1. Remove the starter. follow the paragraph «Starter» in this section.

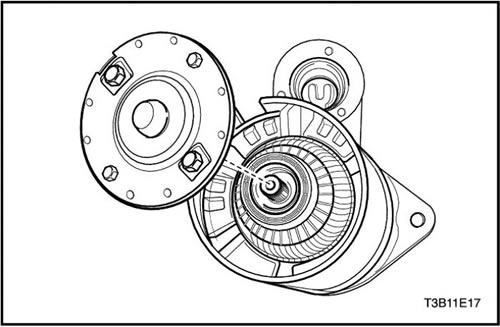

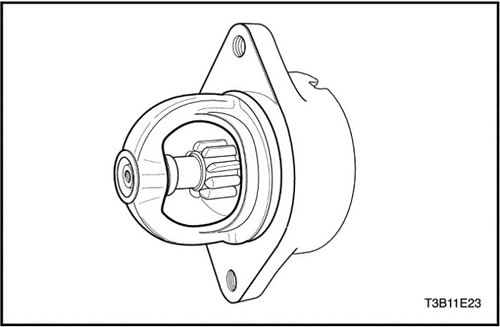

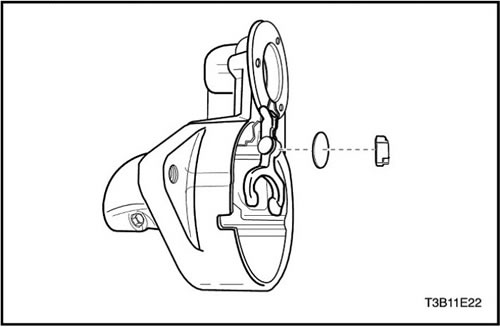

2. Remove the starter through screws.

3. Remove the commutator end piece and brush holder.

4. Check brushes, protruding springs and brush holders for wear and damage. Replace the assembly if necessary.

5. Check the anchor for free play. If the armature does not rotate freely, disassemble the assembly from step 14. Otherwise, test the armature without load.

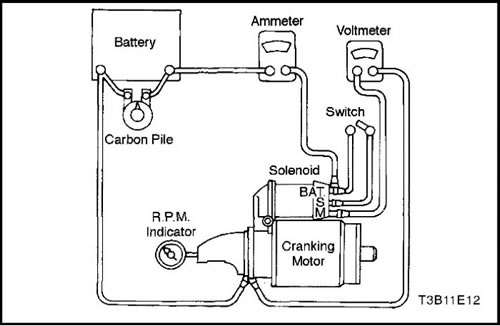

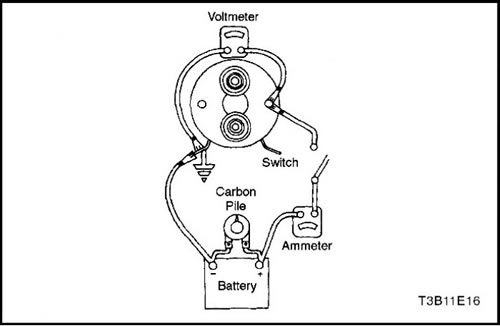

Note: Perform the test in the shortest possible time so as not to overheat and damage the electromagnetic relay.

Important: If the rated current consumption does not include an electromagnetic relay, subtract the rated current consumption from the value of the self-locking winding.

6. To start the no-load test, close the switch and compare the RPM and voltage to specifications. follow the paragraph «Starter Specifications» in this section. Disconnect only with the switch open. Use the test results as follows:

- If the current consumption and no-load speed are within specifications, then the starter motor is OK.

- Low RPM with high current consumption indicates increased friction caused by over tightened, dirty or worn bearings, a bent armature shaft, a short on the armature shaft or field coils.

- Immobility of the starter at high current consumption can be caused by a short to ground of the terminals or windings or "stuck" bearings.

- The immobility of the starter in the absence of current consumption can be caused by an open circuit in the armature windings, broken or worn brush springs, high resistance between the commutator fins, or other reasons that prevent good contact between the brushes and the commutator.

- Low no-load speeds and low current indicate high internal resistance and high current consumption, which are usually caused by shorted field coils.

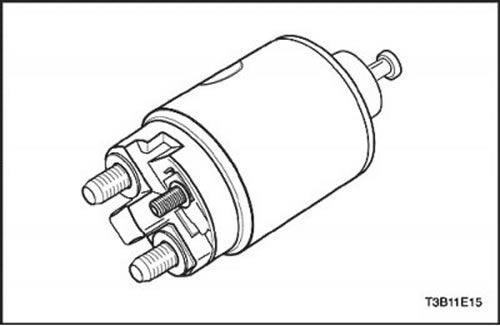

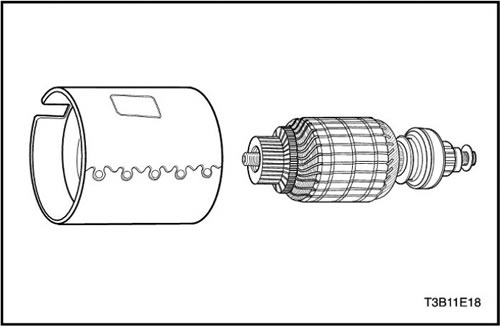

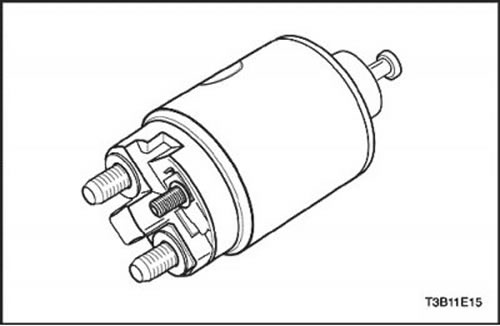

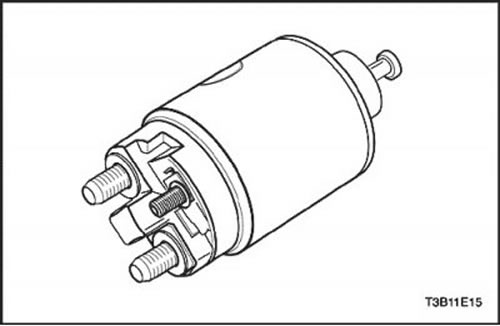

7. Remove the solenoid relay screws.

8. Remove the drive coil connector nut. Disconnect the exciter coil connector.

9. Remove return spring.

Important: If the solenoid relay is not removed from the starter, you must remove the connectors from the solenoid relay terminals before performing this test.

10. Check the coils of the electromagnetic relay by measuring the current drawn.

- Check the self-locking windings by connecting an ammeter in series with the 12-volt battery, switch, and ground.

- Connect the carbon film resistor to the battery.

- Adjust the voltage to 10 V. The ammeter should read between 13 and 19 A. The current will drop as the windings heat up. The current consumption below the technical specifications indicates a short circuit or a short circuit to ground in the winding. Both require replacement of the electromagnetic relay. The current consumption above the technical specifications indicates an increased resistance. The absence of current indicates an open circuit.

Important: The current will drop as the windings heat up. The current consumption below the technical specifications indicates a short circuit or a short circuit to ground in the winding. Both require replacement of the electromagnetic relay. The current consumption above the technical specifications indicates an increased resistance. The absence of current indicates an open circuit.

11. Check both windings by connecting them according to the previous check.

- Connect the solenoid relay terminal to ground.

- Adjust the voltage to 10 V. The ammeter should read between 59 and 79 A.

- Check connections and replace solenoid relay if necessary.

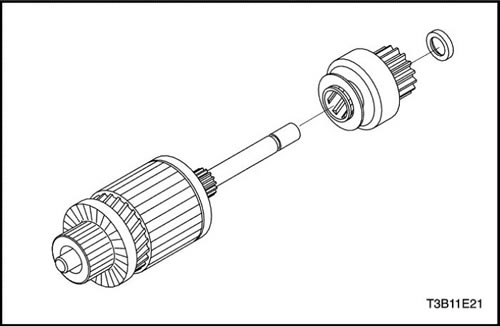

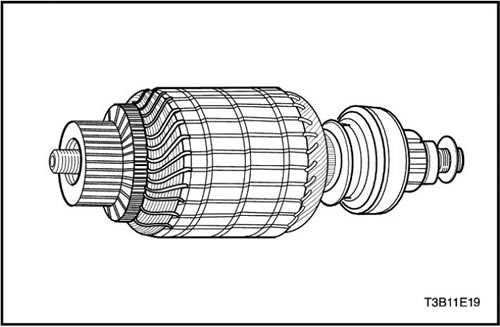

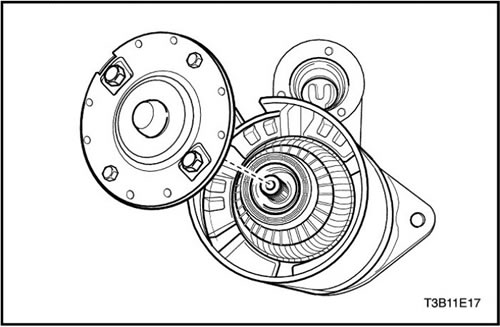

12. Remove the armature stator from the starter assembly.

13. Remove the cover.

14. Remove the stator from the anchor.

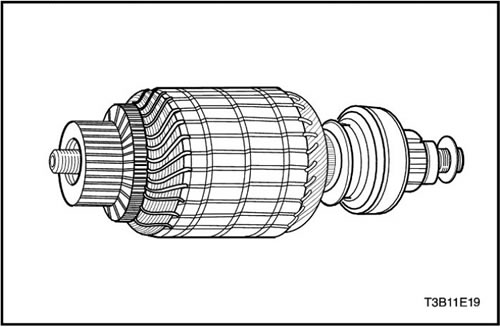

15. Check the shaft and gears for discoloration, breakage or wear. Replace if necessary.

16. Check the armature manifold. If the collector is rough, it needs to be turned. The outer diameter of the collector must be at least 26.9-27.1 mm (1.059-1.067 inches) after turning or cutting. Do not grind eccentric manifolds.

17. Check the places where the armature wires are in contact with the collector lamellas. Make sure you have good contact. Burnt collector lamellas indicate poor contact.

18. If test equipment is available, test the armature for a short circuit by placing it on the tester and holding the saw blade on the armature core and rotating the armature. If the saw blade vibrates, replace the anchor.

19. Check the anchor after cleaning the anchor blades. If the saw blade vibrates, replace the anchor.

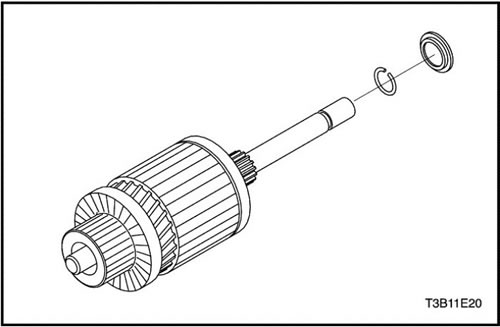

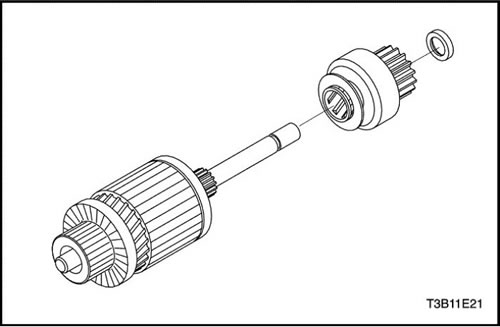

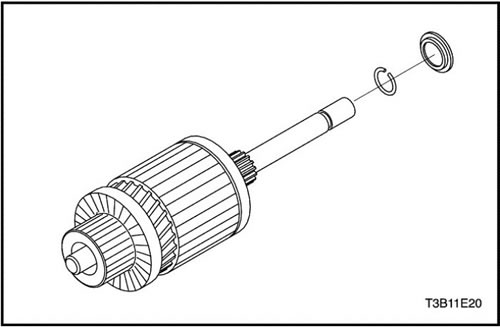

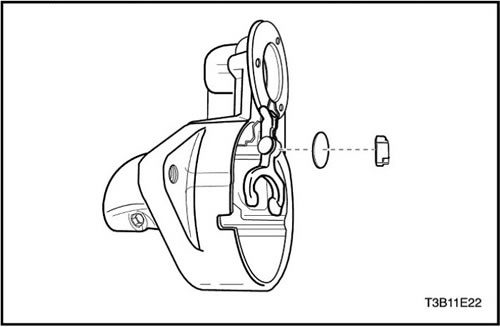

20. Remove the circlip from the groove in the drive shaft.

21. Remove thrust ring and gear from shaft.

22. If not done in the previous steps, remove the screws holding the solenoid relay to the housing and remove the nut from the field coil connector.

23. Rotate the relay 90 degrees and remove it along with the return spring.

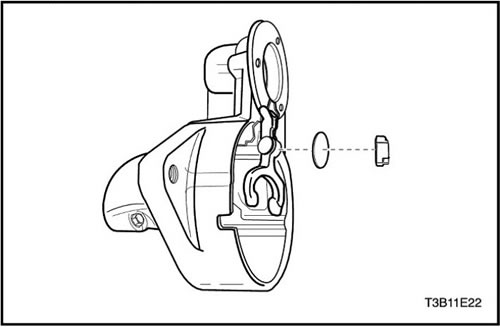

24. Remove the piston with a protective cover and a starting lever. Check the solenoid coils if not done in step 11.

Important: Gear clearance must be correct so that the lugs on the start lever collar do not hit the connecting flange during start.

25. After disassembling the starter and replacing the electromagnetic relay, it is necessary to check the gear clearance.

26. Disconnect the exciter coil connector from the solenoid relay terminal and carefully insulate the connector.

27. Attach one 12 volt wire to the solenoid relay terminal and the other to the starter housing.

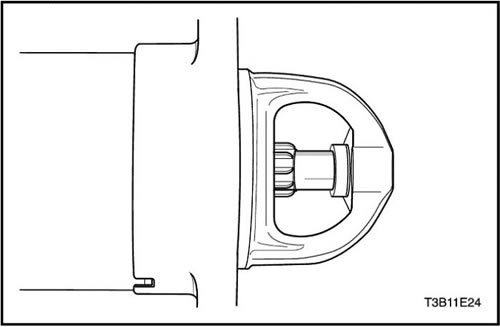

28. Using a ground wire, make a short contact between the solenoid valve connector and the starter housing so that the gear is in the start position and remains there until the battery is disconnected.

Important: There is no means to adjust the gear gap on the starter. If the clearance is out of specification, check for proper installation and replace worn parts.

29. Move the gear as far back as possible to absorb any movement and check the gap with a feeler gauge. The gap should be between 0.25 and 3.56 mm (0.01 to 0.14 inches).

Assembly procedure

1. Install thrust washer and gear onto shaft.

2. Install the circlip on the groove of the shaft and insert the flange.

3. Install the trigger lever, washer, and resilient spacer.

4. Lubricate the drive end of the armature shaft.

5. Install the solenoid relay assembly.

6. Tighten the electromagnetic relay with screws.

Tighten

Tighten the solenoid relay screws to 8 Nm (71 lb/ft).

7. Install the exciter coil connector to the starter terminal. Install the nut.

Tighten

Tighten the starter coil connector nut to 8 Nm (71 lb-in).

8. Install the armature in the stator.

9. Install the cover on the armature and stator.

10. Install the armature and stator with cover into the starter housing.

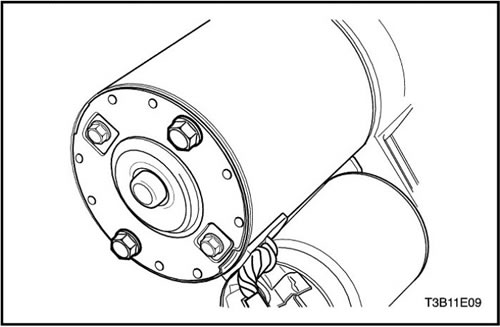

11. Install the end part of the collector and the brush holder, aligning its holes with the through holes in the housing.

12. Install starter through screws.

13. Install starter. follow the paragraph «Starter» in this section.

Tighten

Tighten starter through screws to 6 Nm (53 lb-in).