Cooling system

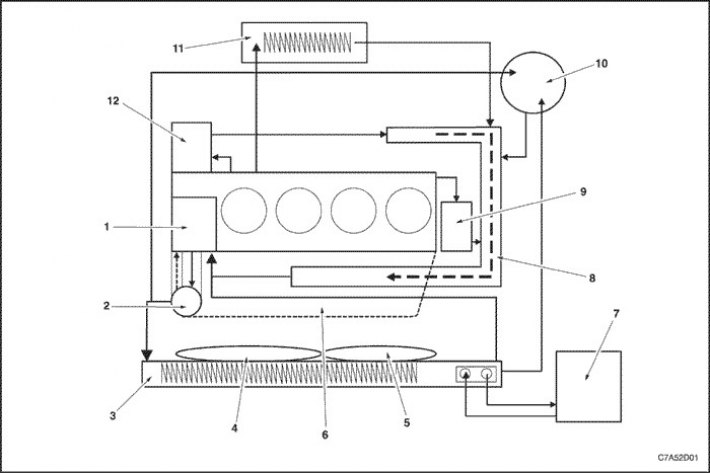

The function of the cooling system is to maintain an efficient engine operating temperature at all engine speeds and under all operating conditions. The cooling system is designed to remove approximately one third of the heat generated by the combustion of the air-fuel mixture. When the engine is cold, no coolant flow enters the radiator until the thermostat opens. This allows the engine to warm up quickly.

1. Water pump

2. Thermostat

3. Radiator

4. Main cooling fan

5. Auxiliary cooling fan

6. Intake manifold

7. Gearbox with final drive assembly

8. water tube

9. Exhaust Gas Recirculation Cooler

10. Expansion tank

11. Heater

12. Engine oil cooler

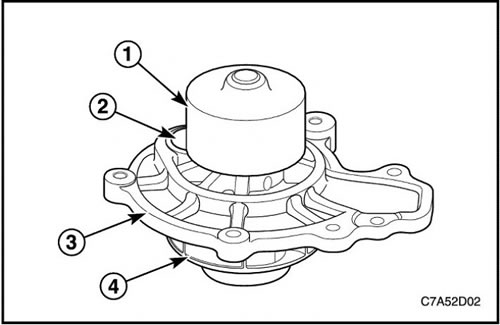

Water pump

The water pump is a component of the engine cooling system and pumps the coolant from each component of the cooling circuit.

This water pump includes a seal, bearing, pulley and housing, and is driven from the crankshaft by the reverse side of the timing belt to dampen the noise from the water pump pulley.

The water pump is provided with a drain cap cup to prevent coolant from spilling onto customers.

The water pump does not have an open type impeller, but a closed type plastic impeller to improve cooling efficiency.

1. Water pump pulley

2. Drain cover cup

3. Frame

4. Impeller

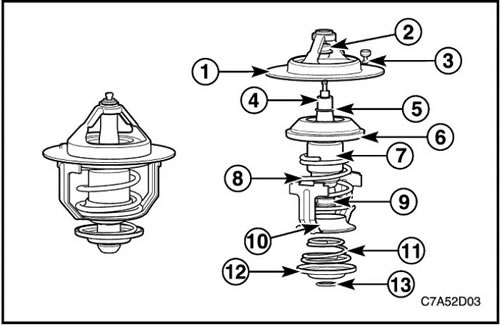

Thermostat

The thermostat controls the flow of coolant and is collected on the intake manifold. Depending on the temperature of the coolant, the wax ball of the thermostat mechanically expands or compresses the mainspring, allowing the flow of coolant.

The thermostat starts to open at 80°C (176°F) and fully opens at 95°C (203°F). Thermostat closes at 75°C (167°F).

1. Saddle

2. Cap

3. float valve

4. Piston

5. Retaining ring

6. rubber valve

7. Assembly element

8. Mainspring

9. bypass shaft

10. frame

11. bypass spring

12. bypass valve

13. Retaining ring

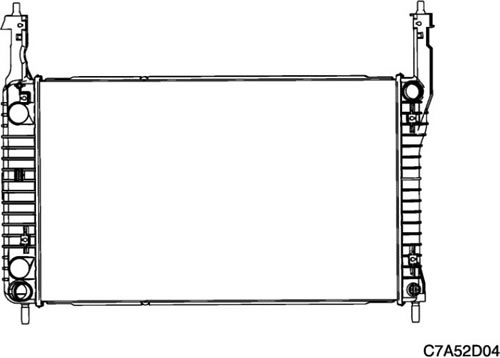

Radiator

The radiator is a heat exchanger. It consists of a core and two tanks. The aluminum core is a cross-flow tube and plate structure that extends from the inlet tank to the outlet tank. Plates are placed around the outside of the tubes to improve heat exchange with the atmosphere.

The inlet and outlet tanks are molded from heat-resistant, polyamide fiber-reinforced plastic. A heat-resistant rubber gasket serves as a seal between the flared lip of the tank and the aluminum core. Tanks are fixed on the core with protrusions with clamps. The lugs are part of an aluminum header at each end of the core.

The radiator also has a drain plug, which is located at the bottom of the left tank. The drain plug assembly includes the drain plug itself and the drain plug seal.

The radiator removes heat from the coolant passing through it. Plates on the core transfer heat from the coolant passing through the tubes. Passing between the plates, the air absorbs heat and cools the coolant.

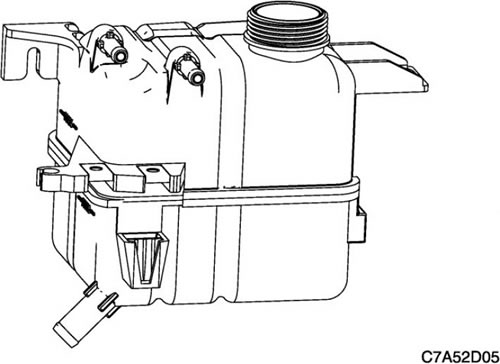

Expansion tank

The expansion tank is a plastic tank with a screw tight cap. The reservoir is mounted at a point above all other coolant passages. The expansion tank provides air space in the cooling system that allows the coolant to expand and contract. The expansion tank serves as a place for filling the coolant and a center for removing air.

When using the vehicle, the coolant heats up and expands. The increasing amount of coolant flows into the expansion tank. As the coolant circulates, all air bubbles are allowed to escape. Coolant without air bubbles absorbs heat much better than coolant with bubbles.

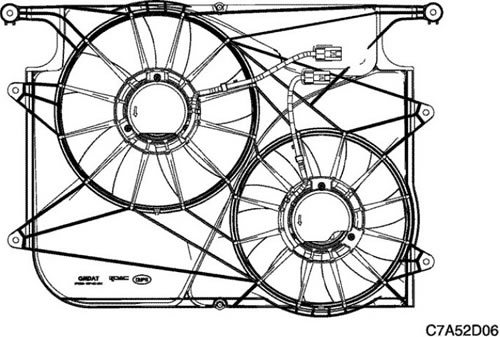

Cooling fan

The cooling fans are installed behind the radiator in the engine compartment. The engine cooling fan is electrically driven. The cooling fan draws air through the radiator to improve heat transfer from the coolant to the atmosphere. As the fan blades rotate, they increase airflow through the radiator core and through the condenser on vehicles equipped with air conditioning. This allows faster cooling at idle or low speeds.