Wheel alignment

|

suspension

|

collapse

|

Angle of longitudinal inclination of the axis of rotation

|

Convergence

|

steering

Steering angle

|

Support

Corner

|

|

front

|

-0.55° ± 0.75°

|

2.18° ± 0.73°

|

0.1° ± 0.08°

|

0.0° ± 2.5°

|

-

|

|

Rear

|

-0.35° ± 0.5°

|

-

|

0.09° ± 0.1°

|

-

|

0.0° ± 0.15°

|

Note: The above specifications refer to the wheel alignment of the vehicle when turned.

Difference between values for left and right wheels

|

PROGRAM

|

front

|

Rear

|

|

collapse

|

1.05°max.

|

0.85°max.

|

|

Angle of longitudinal inclination of the axis of rotation

|

2.91°max.

|

-

|

|

Convergence

|

0.18°max.

|

0.19°max.

|

Tightening torques for threaded connections

|

PROGRAM

|

N·m

|

Pound-foot

|

|

Bolt of fastening of the rear upper suspension arm to the frame

|

110 Nm

|

81 lb-ft

|

|

Nut and bolt of fastening of a rack to a rotary fist

|

180 Nm

|

133 lb-ft

|

|

Tie rod locknut

|

60 Nm

|

44 lb-ft

|

|

Bolt of fastening of the lever of a convergence to a frame

|

110 Nm

|

81 lb-ft

|

Tire diagnostics

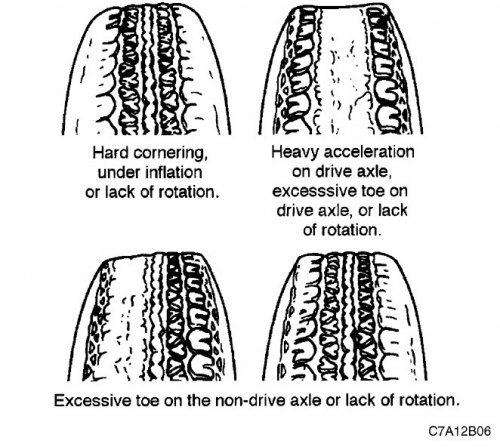

Uneven and premature wear

There are many causes of uneven and premature tire wear. In particular, these include abnormal tire pressure, failure to regularly change wheels, incorrect driving habits, and incorrect wheel alignment. If wheel alignment is due to tire wear, always try to get the toe angle as close to zero as possible within the limits allowed by the specifications. See section in this part «Adjustment of a convergence of back wheels».

Reposition the wheels if:

- Front and rear tire wear is not the same.

- The wear of the left and right front tires is not the same.

- The wear of the left and right rear tires is not the same.

Check wheel alignment if:

- The wear of the left and right front tires is not the same.

- The tread of any of the front tires is worn unevenly.

- The tread of the front tires has sharp edges on the side of the flange or blocks.

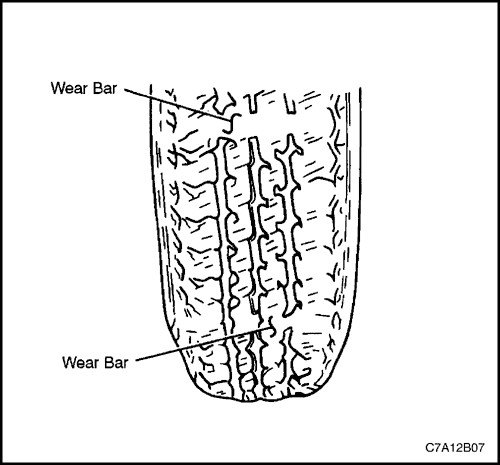

Tread wear indicators

Tires fitted by the vehicle manufacturer have their own tread wear indicators to help you know when your tires need to be replaced. These indicators become visible in the form of stripes with a strong decrease in the depth of the tread grooves. Replacement is recommended when indicators are visible in three or more grooves in six locations.

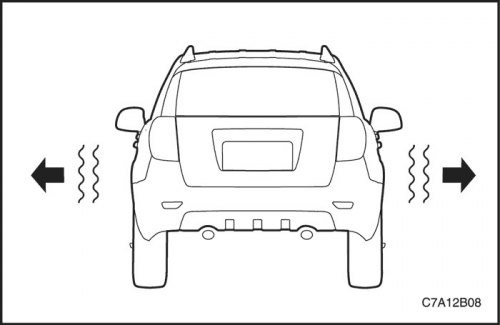

Swinging radial tires

Swing is the movement from side to side of the front or rear of the vehicle. Its cause is the curvature of the steel belt inside the tire, or excessive lateral runout of the tire or wheel. It is most noticeable at low speeds, from 8 to 48 km/h (5 to 30 mph), but may also appear as high-frequency vehicle vibration when driving at speeds from 80 to 113 km / h (50 to 70 mph).

To determine where the faulty tire is, you need to make a test drive. If the defective tire is installed at the rear, the rear of the car will sway. In the driver's seat, it feels like someone is pushing the car sideways. If the faulty tire is at the front, then the wobble can be seen visually. It looks as if the front surface of the car body moves back and forth, and the driver's seat is the center of rotation of the car.

The cause of swaying can be determined by sequentially replacing wheels with tires with known good ones.

1. To determine if the faulty tire is in the front or rear, a test drive must be made.

2. Install, where the malfunction occurs, serviceable tires and wheels taken from a car of the same model. If it is unclear where the bad tire might be, replace the rear tires.

3. Carry out a test drive. If improvement is achieved, then install the old tires to determine the faulty one. If improvement is not achieved, then replace all four tires with serviceable ones.

4. To identify a faulty tire, install the old tires one at a time.

Side slip of a radial tire

Side slip is the deviation of the vehicle from a straight line on a level road in the absence of any force applied to the steering wheel. Common causes of side slip are:

- Incorrect wheel alignment.

- Inconsistency in brake adjustment.

- Tire construction.

Tire design features can cause vehicle side slip. Off-center radial tire breakers can introduce lateral forces when the vehicle is moving straight down the road. If the diameter of the tires on one side is slightly larger than on the other, then the tire will tend to turn in one direction. Inequality in tire diameters will cause a side force that can cause the vehicle to roll.

We recommend that you use a table to diagnose side slip, which allows you to determine whether this malfunction is related to wheel alignment or tires. When performing diagnostics, in some cases it is required to rearrange the wheels in a sequence that differs from the normal one. If a tire with medium or high mileage is moved to the other side of the vehicle, high-frequency vibration should be expected. The rear tires do not cause side slip.

Table for diagnosing the side slip of radial tires

| Step | Operation | Values | Yes | No |

| 1 |

Does the car roll sideways?

|

-

|

Go to Step 2

|

System OK

|

| 2 |

Does the car roll sideways?

|

-

|

Go to Step 3

|

System OK

|

| 3 |

Check the front wheel alignment.

Do the mounting angles meet the required specifications?

|

-

|

Go to Step 4

|

Perform installation angle adjustment

|

| 4 |

Compare the camber and caster values with the required specifications.

Are they within the required limits?

|

- |

Go to Step 7

|

Go to Step 5

|

| 5 |

Check the car frame.

Is the frame bent?

|

-

|

Go to Step 6

|

Go to Step 1

|

| 6 |

Straighten the frame.

Is the repair finished?

|

-

|

Go to Step 3

|

-

|

| 7 |

Does the vehicle still have side pull?

|

-

|

Go to Step 9

|

Go to Step 8

|

| 8 |

Swap the left front tire/wheel assembly and the left rear tire/wheel assembly and replace the left front tire.

Is the repair finished?

|

-

|

System OK

|

Go to Step 1

|

| 9 |

Does the vehicle still have side pull?

|

-

|

Go to Step 1

|

Go to Step 10

|

| 10 |

Swap the right front tire/wheel assembly and the right rear tire/wheel assembly and replace the right front tire.

Is the repair finished?

|

-

|

System OK

|

Go to Step 1

|

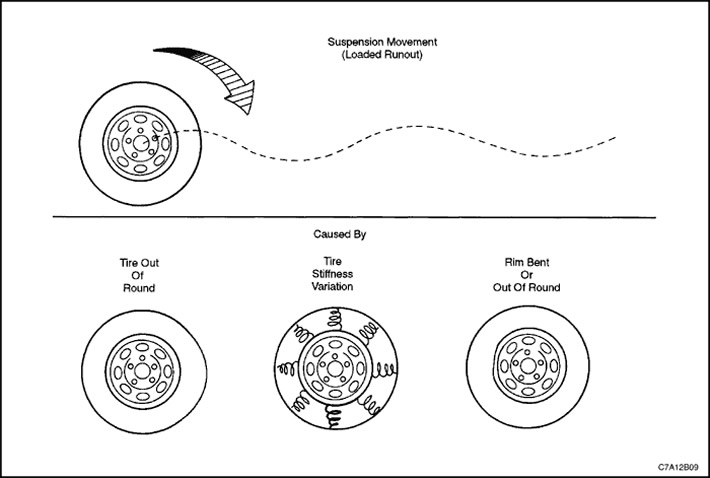

Vibration Diagnostics

In most cases, the cause of vibration at high speeds is wheel imbalance. After dynamic balancing, vibration may persist for the following reasons:

- The tire is deformed.

- The wheel rim is deformed.

- Tire stiffness fluctuates.

Measuring free-running tire and wheel runout reveals only part of the problem. All three causes, known as radial runout under load, should be tested by replacing known good tires and wheel assemblies with bad ones.

The cause of vibrations that occur at low speeds, not exceeding 64 km / h (40 mph), usually is a beat. Cause of vibrations occurring at high speeds exceeding 64 km/h (40 mph) there may be an imbalance or beating.

Preliminary checks

Before starting work, always first make a test drive and carry out a thorough inspection in order to identify the following:

- Explicit runout of the tire with the wheel.

- Explicit runout of the leading axle.

- Under-inflated tires.

- Incorrect body height relative to the wheels.

- Deformed or damaged wheels.

- Mud deposits on a tire or wheel.

- Uneven or excessive tire wear.

- Incorrect position of the tire bead on the wheel rim.

- Tire defects, such as tread warping or peeling, and swelling caused by impact damage. Light dents on the sidewall of a tire are not defects and do not affect ride quality.

Tire balancing

Balancing is the simplest possible operation and if vibration occurs at high speed, then balancing should be done first. First, to correct the imbalance of the tire/wheel assembly, dynamically balance it in two planes by removing the tire/wheel assembly from the vehicle.

The final balancing carried out on the car allows you to eliminate the imbalance associated with the brake drum or disc, or with the wheel cap. If balancing fails to eliminate vibration at high speeds, or if vibration occurs at low speeds, then runout is likely to be the cause.

Beat

The runout can be related to the tire, the wheel, or how the wheel is attached to the vehicle. To determine if wheel runout is possible, refer to the procedures below and use the table in this section for diagnosing wheel runout.

1. If runout is suspected, measure the lateral and radial runout of the tire and wheel assembly while the vehicle is free to rotate. See Part 2E. Tires and wheels. These values must be less than 0.8 mm (0.03 inch). If any of the obtained values is greater, then go to Step 2.

2. Mount the tire and wheel on a dynamic balancer and re-measure the lateral and radial runout in free rotation. Record the values of lateral and radial runout during free rotation and the location of the points that gave the largest values. See Part 2E. Tires and wheels. If these values exceed 1.0 mm (0.04 inch) on the tire tread, then go to Step 4.

3. Measure wheel runout. See Part 2E. Tires and wheels. If the wheel is out of specification, replace it.

4. Release the air from the tire and fit-mount the tire on the wheel so as to bring the point of the tire with a large radial runout as close as possible to the point of the wheel with a small radial runout. Inflate the tire and place the wheel with the tire on a dynamic balancer. Measure and record the radial and lateral free-running values and their locations. In many cases, balancing the tire and wheel by selection-mounting ensures that the runout of the tire and wheel assembly during free rotation is obtained within the allowable range of values not exceeding 1.0 mm (0.04 inch).

5. If the runout of the tire and wheel assembly removed from the vehicle during free rotation does not exceed 1.0 mm (0.04 inch), and after installation on the car exceeds 1.0 mm (0.04 inch), then the probable cause of the vibration is related to the installation of the wheel on the hub. Tighten any two wheel nuts and measure runout again. See Part 2E. Tires and wheels. It may be necessary to perform this operation several times in different places to determine which nuts give the best result.

6. If the runout of the tire and wheel assembly cannot be reduced to less than 1.0 mm (0.04 inch), then remove the assembly.

- Measure hub stud runout with a dial indicator with a magnetic base.

- Zero the indicator on one of the pins.

- Carefully remove the indicator probe from the stud. Rotate the flange so that the next stud is opposite the indicator probe.

- Record the runout values for all studs. When returning to the first of the checked pins, the indicator should show zero.

- If the runout is greater than 0.04 mm (0.002 inch), the hub stud or hub and bearing assembly must be replaced.

It is necessary to re-balance after each change in the position of the tire relative to the wheel or replacement of the wheel or tire.

Table for diagnosing wheel runout

| Step | Operation | Values | Yes | No |

| 1 |

Carry out a test drive to make sure vibration occurs.

Are the customer's complaints validated?

|

-

|

Go to Step 2

|

System OK

|

| 2 |

Has the vibration persisted?

|

-

|

Go to Step 3

|

System OK

|

| 3 |

Determine the speed at which the vibration occurs.

Is there vibration at speeds over 64 km/h (40 mph)?

|

-

|

Go to Step 4

|

Go to Step 6

|

| 4 |

Perform dynamic wheel balancing by removing it from the vehicle.

Has the vibration persisted?

|

-

|

Go to Step 5

|

System OK

|

| 5 |

Carry out final balancing on the vehicle.

Has the vibration persisted?

|

-

|

Go to Step 6

|

System OK

|

| 6 |

Check the lateral and radial runout of the suspended wheel on the vehicle.

Is the beat equal to the required value?

|

0.8mm (0.03 inch)

|

Go to Step 4

|

Go to Step 7

|

| 7 |

Check the lateral and radial runout of the wheel removed from the vehicle.

Is the beat equal to the required value?

|

1.0mm (0.04 inch)

|

Go to Step 8

|

Go to Step 12

|

| 8 |

Is the beat equal to the required value?

|

0.04mm (0.002 inch)

|

Go to Step 9

|

Go to Step 14

|

| 9 |

Perform dynamic wheel balancing by removing it from the vehicle.

Has the vibration persisted?

|

-

|

Go to Step 10

|

System OK

|

| 10 |

Carry out final balancing on the vehicle.

Has the vibration persisted?

|

-

|

Go to Step 11

|

System OK

|

| 11 |

Have the problems been fixed?

|

-

|

Go to Step 1

|

-

|

| 12 |

Is the beat equal to the required value?

|

0.8mm (0.03 inch)

|

Go to Step 9

|

Go to Step 13

|

| 13 |

Is the beat equal to the required value?

|

0.8mm (0.03 inch)

|

Skip to step 15

|

Step 16

|

| 14 |

Measure the hub flange runout.

Is the beat equal to the required value?

|

0.04mm (0.002 inch)

|

Go to Step 9

|

Skip to step 17

|

| 15 |

Replace tire.

Is the repair finished?

|

-

|

Go to Step 1

|

-

|

| 16 |

Replace wheel.

Is the repair finished?

|

-

|

Go to Step 1

|

-

|

| 17 |

Replace hub.

Is the repair finished?

|

-

|

Go to Step 1

|

-

|

Preview

|

Checks

|

operation, action

|

|

Check for abnormal tire pressure and tread wear.

|

Inflate tires to the required pressure. Change tires if necessary.

|

|

Check for play in the wheel bearings.

|

Replace hub and bearing assembly.

|

|

Check ball joints and tie rod ends for play.

|

Tighten ball joints and tie rod ends.

|

|

Check wheel and tire runout.

|

Measure and adjust tire runout.

|

|

Check the height of the body relative to the wheels.

|

Adjust the height of the body relative to the wheels. Make these adjustments before adjusting the toe.

|

|

Check the rack and pinion steering gear for play.

|

Tighten rack and pinion assembly.

|

|

Check the correct operation of the telescopic struts.

|

Replace the telescopic pole assembly.

|

|

Check the levers for play.

|

Tighten the lever mounting bolts. Replace arm bushings if required.

|

Adjusting the angle of the longitudinal inclination of the axis of rotation of the front wheels

The angle of the longitudinal inclination of the axis of rotation of the front wheels is not subject to adjustment. If the caster angle of the front wheels is not within specifications, check that the suspension mount is installed correctly and that the front suspension is damaged. Replace damaged suspension parts if necessary.

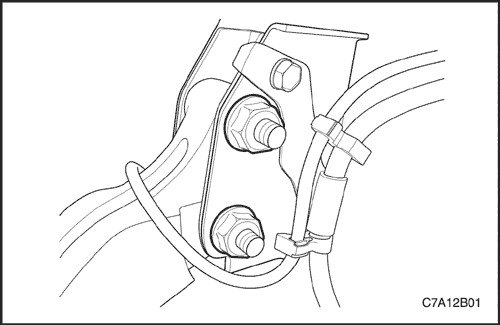

Front camber adjustment

1. Raise and place the vehicle on stands.

2. Remove tires and wheels as an assembly.

3. Remove the nuts and bolts securing the strut to the steering knuckle. Discard nuts and bolts.

4. If the rack has not been modified before, perform the following procedure:

- Disconnect the strut from the steering knuckle.

- If negative camber increases, remove material from the outside of the lower strut hole.

- If negative camber decreases, remove material from the inside of the lower strut hole.

5. Install new bolts and put on new nuts securing the strut to the steering knuckle.

6. Adjust the camber to the required specifications, moving the top of the tire in or out as necessary.

7. Tighten the rack nuts and bolts.

Tighten

Tighten the nuts and bolts until a torque of 180 Nm is reached (133 lb-ft).

8. Install tire and wheel assemblies.

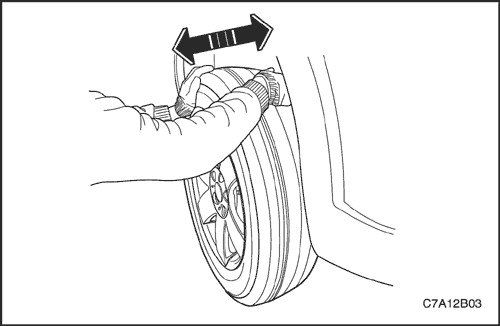

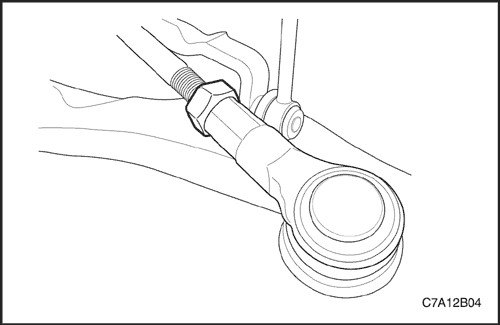

Adjustment of a convergence of forward wheels

1. Move the steering wheel to this position and fix it so that the wheels of the car are pointing straight ahead.

2. Loosen both inner tie rod locknuts.

Important: The inner tie rod must rotate freely without touching the sealing surface of the boot. Do not allow the cover to rotate.

3. Loosen the inner tie rod seal against the boot surface.

4. Use a wrench and flats on the tie rod to increase or decrease toe angle specifications.

5. Tighten the inner tie rod locknuts.

Tighten

Tighten the locknuts until a torque of 60 Nm is reached (44 lb-ft).

6. Check toe angle to ensure correct adjustment and adjust if necessary.

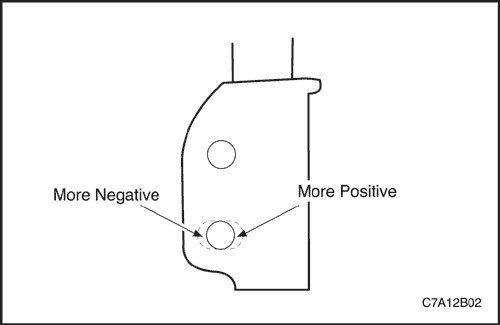

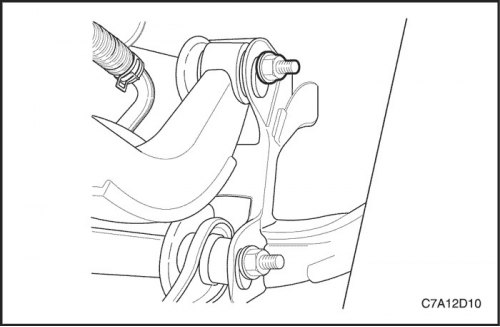

Rear camber adjustment

1. Loosen upper suspension arm to frame just enough to allow movement.

Important: There are grooves on the car frame, by turning the cam nut, you can move the camber to the indicated position.

2. Rotate the upper control arm mount in the direction needed to measure the camber correctly.

3. Firmly seat the upper suspension arm mount to the frame without tightening it.

4. Repeat the rear camber specification test and adjust if necessary.

5. While holding the nut, tighten the bolt securing the upper suspension arm to the frame.

Tighten

Tighten the bolt until a torque of 110 Nm is reached (81 lb-ft).

6. Repeat this procedure for the other rear wheel.

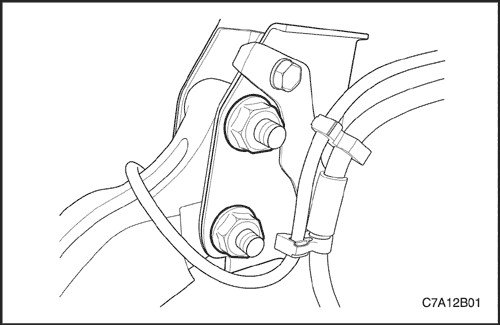

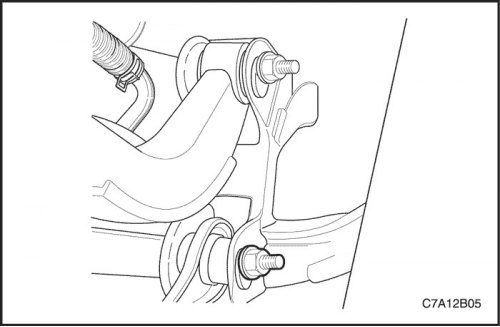

Adjustment of a convergence of back wheels

1. Loosen toe arm to frame just enough to allow movement.

2. Turn the toe lever cam nut in the direction needed to correct the toe angle.

3. Firmly seat the toe lever mount to the frame without tightening it.

4. Repeat the rear wheel toe specification test and adjust if necessary.

5. While holding the nut, tighten the bolt securing the arm to the frame.

Tighten

Tighten the bolt until a torque of 110 Nm is reached (81 lb-ft).

6. Repeat this procedure for the other rear wheel.

Adjustment of angles of installation of all four wheels

The first responsibility of designers is to create safe steering and suspension systems. Each element must have a strength sufficient to withstand the impact of ultimate loads. Both the steering and the rear and front suspensions must function in such a way as to maintain geometric characteristics in the presence of body weight.

In order to drive the engine with minimum effort and maximum comfort, the steering and suspension must ensure that the front wheels self-return and maintain negligible values of tire rolling force and rolling friction force.

A complete wheel alignment check should include rear toe and camber measurements.

Adjusting the angles of the installation of all four wheels ensures that the wheels move in exactly the same direction.

A vehicle that has been geometrically adjusted has the best fuel consumption and tire life, and its handling and performance are maximized.

Convergence

With a positive convergence, the wheels are turned inward, and with a negative one, they are turned outward relative to the geometric center line or the line of action of the thrust. The convergence provides parallel movement of the wheels.

Toe-in serves to compensate for small deviations in the wheel mounting system that occur when the car moves forward. The angle of convergence, which must be obtained during adjustment, is such a convergence, which becomes equal to zero degrees when the car is moving.

Incorrect positive or negative toe will result in tire wear and increased fuel consumption. Since the steering and suspension components wear as the vehicle is used, additional toe adjustment will be required to compensate for this wear.

Always adjust toe last.

Angle of longitudinal inclination of the axis of rotation

The caster angle is the angle at which the top of the steering axle is tilted forward or backward from the vertical when viewed from the side of the vehicle. Tilt back is positive and forward is negative. The caster angle affects the ability of the steering to maintain the desired course of the vehicle, but does not affect tire wear. The caster angle is affected by the weakening of the springs and the overloading of the vehicle. A wheel with a smaller caster angle will move towards the center of the vehicle. In this case, the vehicle will move or lean towards the wheel that has a smaller positive caster angle. The pitch angle is measured in degrees and cannot be adjusted.

Collapse

Camber is the deviation of the top of the tire from the vertical when viewed from the front of the vehicle. If the tires are tilted outward, then the camber is positive. If the tires are tilted inward, then the camber is negative. The camber angle is measured in degrees relative to the vertical. Camber affects both the ability to keep the desired course of the car, and tire wear.

If the vehicle's positive camber is too high, the outer shoulder area of the tire will wear out. If the negative camber of the car wheel is too large, then the inner shoulder area of the tire will wear out.

Pivot Tilt

The inclination of the axis of rotation is the deviation of the upper point of the steering knuckle from the vertical. The steering axis angle is measured between true vertical and a line through the center of the strut and the lower ball joint as viewed from the front of the vehicle.

Pivot tilt helps keep the vehicle in a straight line and return the wheel to the straight line. The tilt of the steering axis for vehicles with front-wheel drive axles must be negative.

Integral angle

The included angle is the angle measured from the camber angle to a line through the center of the strut and the lower ball joint as viewed from the front of the vehicle.

The included angle is calculated in degrees. Most angle stands do not directly measure the included angle. Integral angle can be determined by subtracting negative camber from the skew, or by adding positive camber to the skew.

Run-in shoulder

The run-in shoulder is the distance along the road surface between the true vertical and the line passing through the center of the strut and the lower ball joint. The run-in shoulder is built into the design of the car. The roll arm is not adjustable.

Shift back, delay

Backward offset is the distance that a front hub and bearing assembly can be moved relative to the other front hub and bearing assembly. The shift back is mainly due to road obstacles or collision.

Angle of rotation

Steering angle is the angle of rotation of each of the front wheels about the vertical axis when the car makes a turn.