Wheel runout

Measure wheel runout with an accurate dial indicator. Measurements can be taken without removing the wheels from the vehicle, or by removing them and placing them on a suitable flat surface, such as on a wheel balancer. Measurements can be performed with or without a tire.

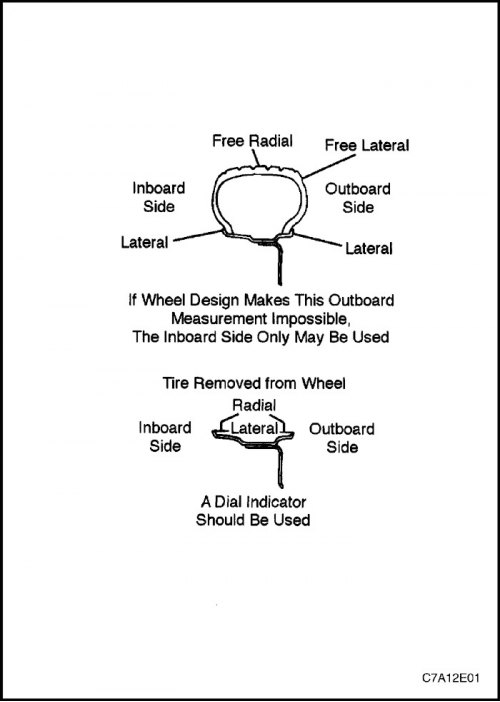

Measure the radial and lateral runout on both the inner and outer flange of the rim. With the dial indicator securely positioned near the wheel and tire assembly, slowly rotate the wheel one revolution and record the indicator reading. If the result of any measurement is greater than the value indicated in the technical data, and there is doubt about the correct balance of the wheel, then the wheel should be replaced. Ignore indicator readings due to welds, paint drips, or scratches.

Measure the radial runout of a freely rotating wheel at the center of the tread. To make the surface of the protector smooth, you can stick an adhesive tape on it. Measure the lateral runout of a freely rotating wheel on the outer sidewall of the tire, as close to the tread as possible.

Steel/alloy wheels

- Radial runout: 0.8mm (0.03 inch)

- Lateral runout: 1.0mm (0.04 inch)