Attention! Brake fluid can cause eye and skin irritation. In case of contact with eyes or skin, the following measures should be taken:

- Contact with eyes - rinse with plenty of water.

- Skin contact - wash with soap and water.

- If swallowed, seek medical attention immediately.

Note: Avoid spilling liquid on connections, wires and cables. Brake fluid will damage painted surfaces and corrode electrical components. If brake fluid comes into contact with painted surfaces, wash the area immediately with water. If brake fluid gets on electrical connections, wires or cables, wipe off the fluid with a clean cloth.

Removal procedure

1. Turn the ignition switch to the OFF position.

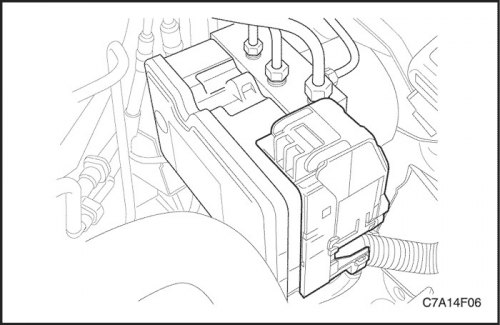

2. Remove the engine coolant reservoir and fuse box. See Section 1D2, Engine Cooling System (FAM II 2.4 D) and Section 1E2 Engine Electrical System (FAM II 2.4 D).

3. Clean the fitting area of the brake modulator tube assembly of accumulated dirt and foreign material.

4. Disconnect the electrical connector from the brake controller (EBCM).

5. Place a towel under the brake modulator assembly to soak up leaking brake fluid.

Important: Before disconnecting the brake lines from the anti-lock brake system modulator assembly (ABS) the position of the brake lines relative to the valve assembly must be recorded to facilitate subsequent reassembly.

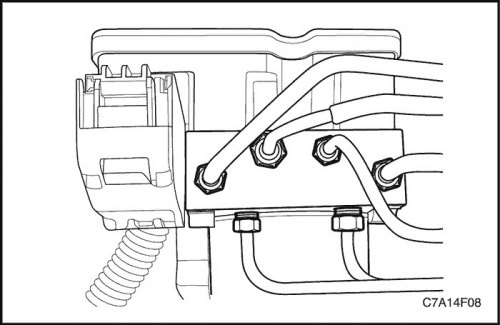

6. Disconnect the tube fitting nut from the brake pressure modulator valve (BPMV).

7. Close the ends of the brake pipes to prevent fluid spillage and environmental contamination.

8. Close the openings of the brake pipes of the modulator to prevent spillage of fluid and pollution of the environment.

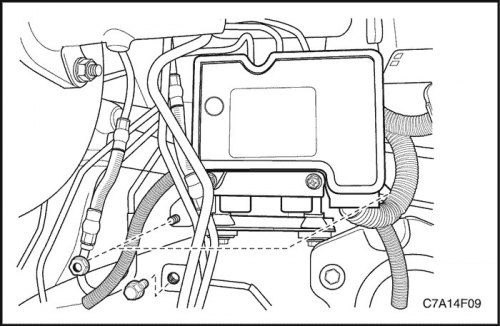

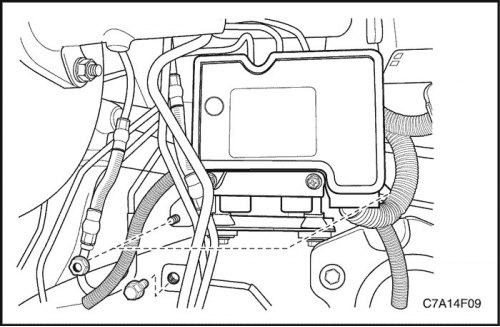

9. Remove the bracket bolt and nuts from the body panel.

10. Loosen the damping bolts securing the brake modulator assembly to the bracket.

Installation procedure

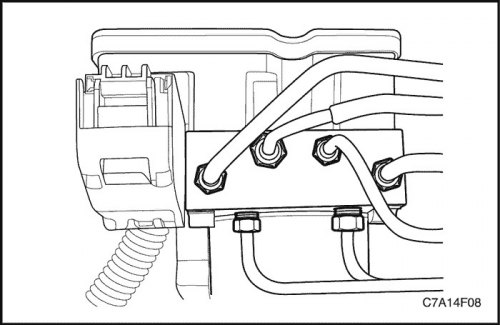

1. Install the damping mounting bolts on the brake modulator assembly.

Tighten

Tighten the damping bolts of the brake modulator assembly to 11 Nm (8 lb-ft).

2. Install the brake modulator assembly on the bracket.

3. Install the brake modulator assembly with the bracket attached to the body panel.

Tighten

Tighten the bolts and nuts securing the bracket to a torque of 10 Nm (89 lb-in).

4. Remove the caps from the ends of the brake master cylinder tubes.

5. Remove the plugs from the master cylinder bores on the modulator assembly.

6. Connect the brake master cylinder tubes to the modulator assembly, in the same place where they were removed.

7. Tighten the brake pipe fitting nuts.

Tighten

Tighten fitting nuts to 16 Nm (12 lb-ft).

8. Connect the electrical connector to the brake controller (EBCM).

9. Install the engine coolant reservoir and fuse box.

10. Bleed the hydraulic brake system. See Part 4A. Hydraulic brakes.

11. Turn the ignition switch to the on position (ON). DO NOT start the engine.

12. Run the diagnostic circuit test in this section.